Are you a seasoned Steel Layer seeking a new career path? Discover our professionally built Steel Layer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

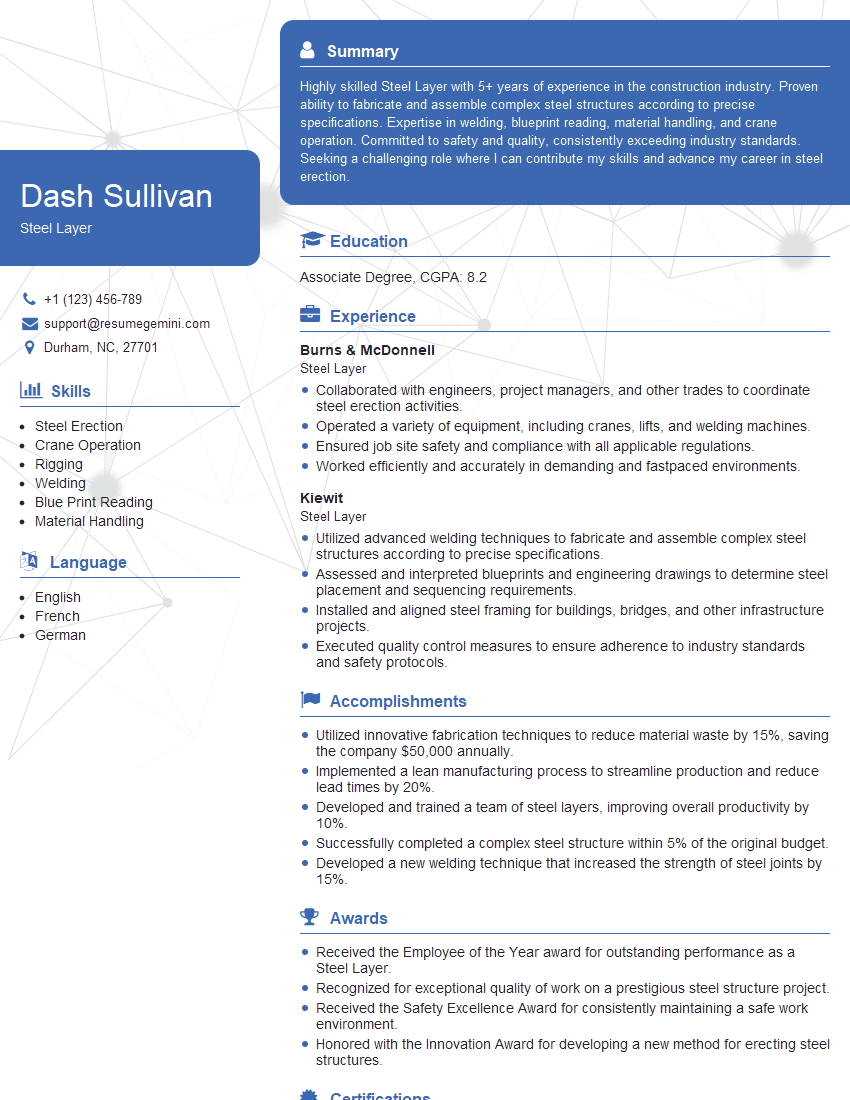

Dash Sullivan

Steel Layer

Summary

Highly skilled Steel Layer with 5+ years of experience in the construction industry. Proven ability to fabricate and assemble complex steel structures according to precise specifications. Expertise in welding, blueprint reading, material handling, and crane operation. Committed to safety and quality, consistently exceeding industry standards. Seeking a challenging role where I can contribute my skills and advance my career in steel erection.

Education

Associate Degree

July 2018

Skills

- Steel Erection

- Crane Operation

- Rigging

- Welding

- Blue Print Reading

- Material Handling

Work Experience

Steel Layer

- Collaborated with engineers, project managers, and other trades to coordinate steel erection activities.

- Operated a variety of equipment, including cranes, lifts, and welding machines.

- Ensured job site safety and compliance with all applicable regulations.

- Worked efficiently and accurately in demanding and fastpaced environments.

Steel Layer

- Utilized advanced welding techniques to fabricate and assemble complex steel structures according to precise specifications.

- Assessed and interpreted blueprints and engineering drawings to determine steel placement and sequencing requirements.

- Installed and aligned steel framing for buildings, bridges, and other infrastructure projects.

- Executed quality control measures to ensure adherence to industry standards and safety protocols.

Accomplishments

- Utilized innovative fabrication techniques to reduce material waste by 15%, saving the company $50,000 annually.

- Implemented a lean manufacturing process to streamline production and reduce lead times by 20%.

- Developed and trained a team of steel layers, improving overall productivity by 10%.

- Successfully completed a complex steel structure within 5% of the original budget.

- Developed a new welding technique that increased the strength of steel joints by 15%.

Awards

- Received the Employee of the Year award for outstanding performance as a Steel Layer.

- Recognized for exceptional quality of work on a prestigious steel structure project.

- Received the Safety Excellence Award for consistently maintaining a safe work environment.

- Honored with the Innovation Award for developing a new method for erecting steel structures.

Certificates

- NCCCO Crane Operator Certification

- OSHA 30-Hour Construction Safety Training

- AWS Certified Welder

- American Concrete Institute (ACI) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Layer

- Highlight your welding skills and experience, emphasizing any certifications or specialized techniques you possess.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on projects.

- Showcase your knowledge of steel erection best practices and safety protocols.

- Include relevant keywords throughout your resume to increase its visibility to potential employers.

Essential Experience Highlights for a Strong Steel Layer Resume

- Utilized advanced welding techniques to fabricate and assemble complex steel structures according to precise specifications.

- Assessed and interpreted blueprints and engineering drawings to determine steel placement and sequencing requirements.

- Installed and aligned steel framing for buildings, bridges, and other infrastructure projects.

- Executed quality control measures to ensure adherence to industry standards and safety protocols.

- Collaborated with engineers, project managers, and other trades to coordinate steel erection activities.

- Operated a variety of equipment, including cranes, lifts, and welding machines.

- Ensured job site safety and compliance with all applicable regulations.

Frequently Asked Questions (FAQ’s) For Steel Layer

What is the role of a Steel Layer?

A Steel Layer is responsible for fabricating, assembling, and installing steel structures according to blueprints and engineering drawings. They work with various types of steel, welding equipment, and tools to create structural frameworks for buildings, bridges, and other infrastructure projects.

What skills are required to be a successful Steel Layer?

Essential skills for a Steel Layer include welding, blueprint reading, material handling, crane operation, and a strong understanding of construction safety protocols. They should also possess physical strength, attention to detail, and the ability to work effectively in a team environment.

What is the career outlook for Steel Layers?

The job outlook for Steel Layers is expected to be positive in the coming years, driven by the increasing demand for infrastructure development and construction projects. Steel Layers with specialized skills and experience can expect to find ample opportunities for advancement.

What are the safety considerations for Steel Layers?

Steel Layers work with heavy machinery and materials, so safety is of paramount importance. They must adhere to strict safety protocols, wear appropriate protective gear, and be aware of potential hazards on the job site.

How can I become a certified Steel Layer?

While certification is not mandatory, it can enhance your credibility and demonstrate your commitment to the profession. There are several organizations that offer certification programs for Steel Layers, including the American Welding Society (AWS) and the National Institute for Steel Detailing (NISD).