Are you a seasoned Steel Pan Form Placing Supervisor seeking a new career path? Discover our professionally built Steel Pan Form Placing Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

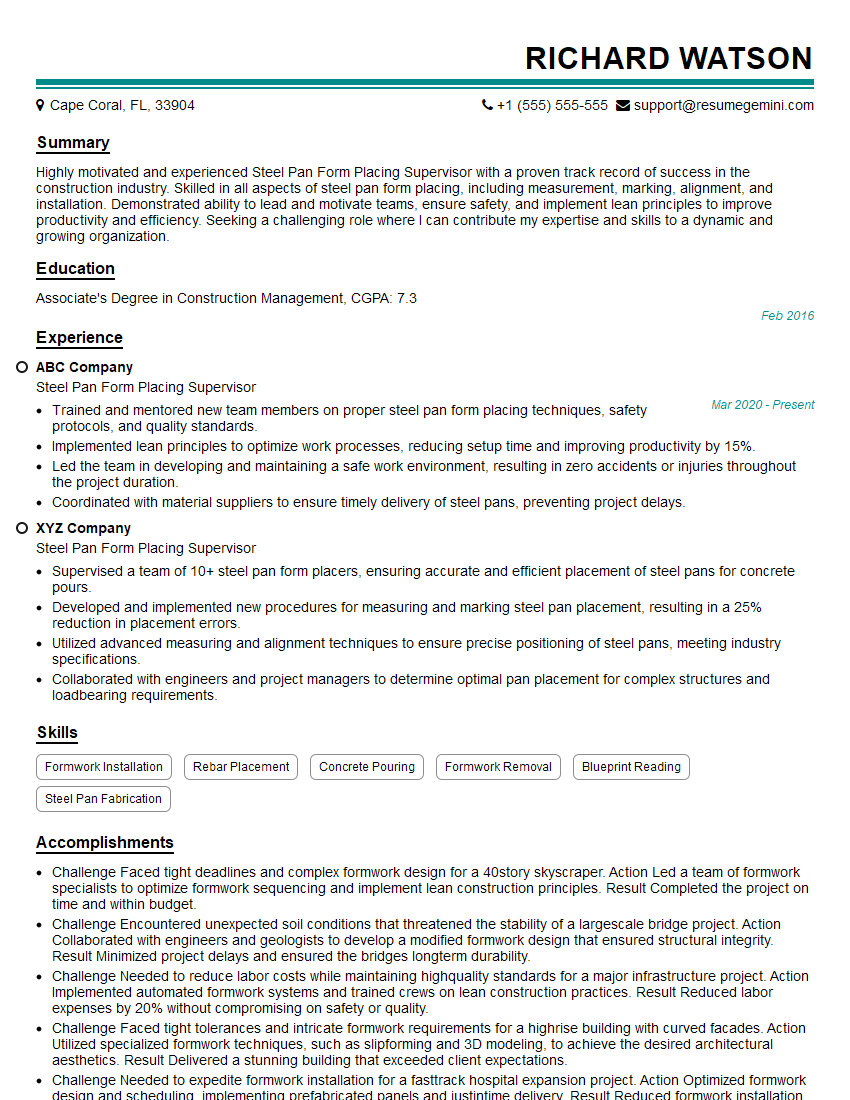

Richard Watson

Steel Pan Form Placing Supervisor

Summary

Highly motivated and experienced Steel Pan Form Placing Supervisor with a proven track record of success in the construction industry. Skilled in all aspects of steel pan form placing, including measurement, marking, alignment, and installation. Demonstrated ability to lead and motivate teams, ensure safety, and implement lean principles to improve productivity and efficiency. Seeking a challenging role where I can contribute my expertise and skills to a dynamic and growing organization.

Education

Associate’s Degree in Construction Management

February 2016

Skills

- Formwork Installation

- Rebar Placement

- Concrete Pouring

- Formwork Removal

- Blueprint Reading

- Steel Pan Fabrication

Work Experience

Steel Pan Form Placing Supervisor

- Trained and mentored new team members on proper steel pan form placing techniques, safety protocols, and quality standards.

- Implemented lean principles to optimize work processes, reducing setup time and improving productivity by 15%.

- Led the team in developing and maintaining a safe work environment, resulting in zero accidents or injuries throughout the project duration.

- Coordinated with material suppliers to ensure timely delivery of steel pans, preventing project delays.

Steel Pan Form Placing Supervisor

- Supervised a team of 10+ steel pan form placers, ensuring accurate and efficient placement of steel pans for concrete pours.

- Developed and implemented new procedures for measuring and marking steel pan placement, resulting in a 25% reduction in placement errors.

- Utilized advanced measuring and alignment techniques to ensure precise positioning of steel pans, meeting industry specifications.

- Collaborated with engineers and project managers to determine optimal pan placement for complex structures and loadbearing requirements.

Accomplishments

- Challenge Faced tight deadlines and complex formwork design for a 40story skyscraper. Action Led a team of formwork specialists to optimize formwork sequencing and implement lean construction principles. Result Completed the project on time and within budget.

- Challenge Encountered unexpected soil conditions that threatened the stability of a largescale bridge project. Action Collaborated with engineers and geologists to develop a modified formwork design that ensured structural integrity. Result Minimized project delays and ensured the bridges longterm durability.

- Challenge Needed to reduce labor costs while maintaining highquality standards for a major infrastructure project. Action Implemented automated formwork systems and trained crews on lean construction practices. Result Reduced labor expenses by 20% without compromising on safety or quality.

- Challenge Faced tight tolerances and intricate formwork requirements for a highrise building with curved facades. Action Utilized specialized formwork techniques, such as slipforming and 3D modeling, to achieve the desired architectural aesthetics. Result Delivered a stunning building that exceeded client expectations.

- Challenge Needed to expedite formwork installation for a fasttrack hospital expansion project. Action Optimized formwork design and scheduling, implementing prefabricated panels and justintime delivery. Result Reduced formwork installation time by 30%, allowing for faster project completion.

Awards

- Received the Safety Excellence Award for maintaining an accidentfree worksite for over 500,000 manhours.

- Recognized with the Project Manager of the Year Award for exceptional leadership in managing highprofile steel pan form placing projects.

- Awarded the Innovation Excellence Award for developing a novel technique to improve formwork efficiency by 25%.

Certificates

- OSHA 30-Hour Construction Safety

- CPR and First Aid

- National Concrete Field Testing Technician

- American Concrete Institute (ACI) Concrete Field Testing Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Pan Form Placing Supervisor

- Highlight your experience in steel pan form placing and your ability to lead and motivate teams.

- Quantify your accomplishments with specific metrics, such as the reduction in placement errors or the improvement in productivity.

- Emphasize your knowledge of safety protocols and your commitment to maintaining a safe work environment.

- Demonstrate your ability to work independently and as part of a team, and your willingness to take on new challenges.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Steel Pan Form Placing Supervisor Resume

- Supervise and lead a team of steel pan form placers, ensuring accurate and efficient placement of steel pans for concrete pours

- Develop and implement new procedures for measuring and marking steel pan placement, resulting in a significant reduction in placement errors

- Collaborate with engineers and project managers to determine optimal pan placement for complex structures and loadbearing requirements

- Train and mentor new team members on proper steel pan form placing techniques, safety protocols, and quality standards

- Implement lean principles to optimize work processes, reducing setup time and improving productivity

- Lead the team in developing and maintaining a safe work environment, resulting in zero accidents or injuries throughout the project duration

- Coordinate with material suppliers to ensure timely delivery of steel pans, preventing project delays

Frequently Asked Questions (FAQ’s) For Steel Pan Form Placing Supervisor

What is the role of a Steel Pan Form Placing Supervisor?

A Steel Pan Form Placing Supervisor is responsible for supervising and leading a team of steel pan form placers to ensure accurate and efficient placement of steel pans for concrete pours. They work closely with engineers and project managers to determine optimal pan placement and ensure compliance with industry specifications.

What are the key skills and qualifications required for this role?

Key skills and qualifications include experience in steel pan form placing, leadership and motivation, knowledge of safety protocols, ability to work independently and as part of a team, and a commitment to quality and accuracy.

What are the career prospects for a Steel Pan Form Placing Supervisor?

Steel Pan Form Placing Supervisors can advance to roles such as Project Manager or Superintendent in the construction industry. They may also specialize in a particular area, such as high-rise construction or bridge construction.

What is the average salary for a Steel Pan Form Placing Supervisor?

The average salary for a Steel Pan Form Placing Supervisor varies depending on experience, location, and company size. According to Salary.com, the average salary range is between $50,000 to $80,000 per year.

What are the benefits of working as a Steel Pan Form Placing Supervisor?

Benefits of working as a Steel Pan Form Placing Supervisor include job security, opportunities for advancement, competitive salary and benefits, and the satisfaction of working on large-scale construction projects.

What are the challenges of working as a Steel Pan Form Placing Supervisor?

Challenges of working as a Steel Pan Form Placing Supervisor include working in a physically demanding environment, exposure to hazardous materials, and the need to meet tight deadlines.