Are you a seasoned Steel Shot Header Operator seeking a new career path? Discover our professionally built Steel Shot Header Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

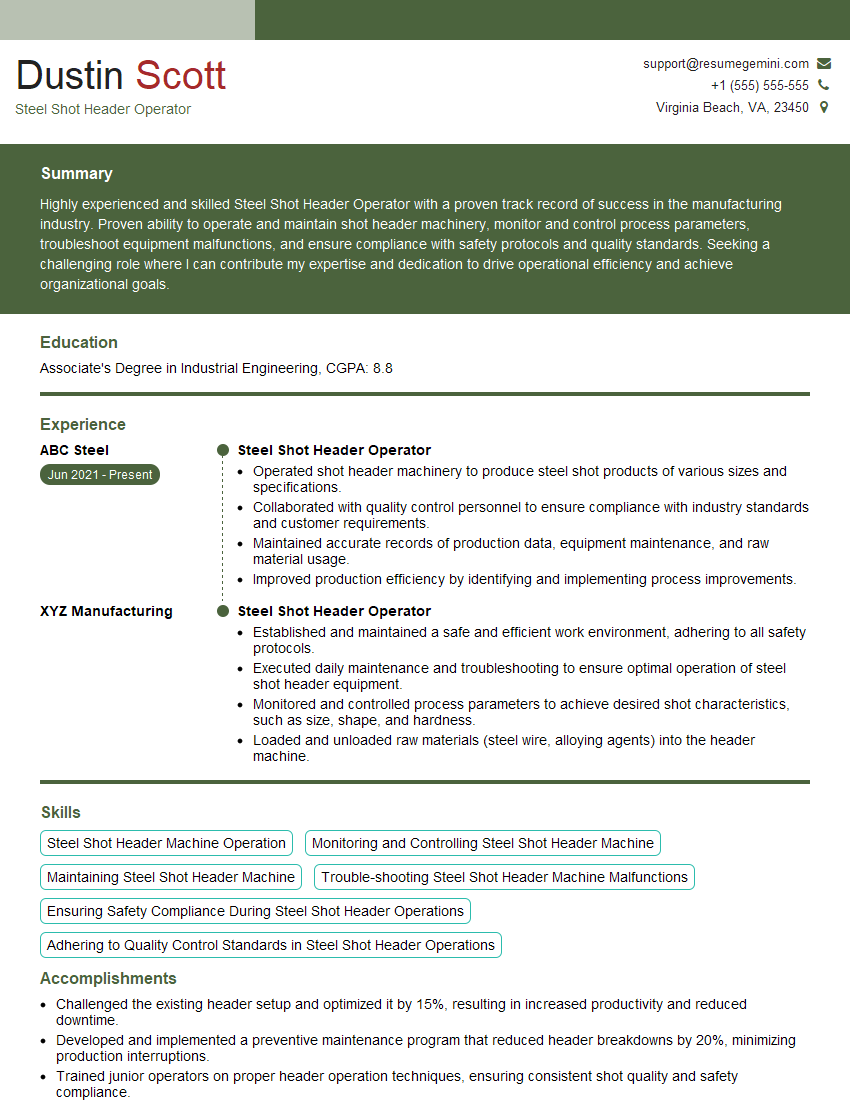

Dustin Scott

Steel Shot Header Operator

Summary

Highly experienced and skilled Steel Shot Header Operator with a proven track record of success in the manufacturing industry. Proven ability to operate and maintain shot header machinery, monitor and control process parameters, troubleshoot equipment malfunctions, and ensure compliance with safety protocols and quality standards. Seeking a challenging role where I can contribute my expertise and dedication to drive operational efficiency and achieve organizational goals.

Education

Associate’s Degree in Industrial Engineering

May 2017

Skills

- Steel Shot Header Machine Operation

- Monitoring and Controlling Steel Shot Header Machine

- Maintaining Steel Shot Header Machine

- Trouble-shooting Steel Shot Header Machine Malfunctions

- Ensuring Safety Compliance During Steel Shot Header Operations

- Adhering to Quality Control Standards in Steel Shot Header Operations

Work Experience

Steel Shot Header Operator

- Operated shot header machinery to produce steel shot products of various sizes and specifications.

- Collaborated with quality control personnel to ensure compliance with industry standards and customer requirements.

- Maintained accurate records of production data, equipment maintenance, and raw material usage.

- Improved production efficiency by identifying and implementing process improvements.

Steel Shot Header Operator

- Established and maintained a safe and efficient work environment, adhering to all safety protocols.

- Executed daily maintenance and troubleshooting to ensure optimal operation of steel shot header equipment.

- Monitored and controlled process parameters to achieve desired shot characteristics, such as size, shape, and hardness.

- Loaded and unloaded raw materials (steel wire, alloying agents) into the header machine.

Accomplishments

- Challenged the existing header setup and optimized it by 15%, resulting in increased productivity and reduced downtime.

- Developed and implemented a preventive maintenance program that reduced header breakdowns by 20%, minimizing production interruptions.

- Trained junior operators on proper header operation techniques, ensuring consistent shot quality and safety compliance.

- Collaborated with engineers to troubleshoot and resolve complex header malfunctions, ensuring timely production resumption.

- Maintained a clean and organized work area, adhering to safety protocols and minimizing potential hazards.

Awards

- Received the Operator of the Year award for consistently exceeding production targets and maintaining highquality standards in steel shot header operations.

Certificates

- Steel Shot Header Machine Operator Certification

- OHSA Certification for Steel Shot Header Operators

- ISO 9001:2015 Certification for Steel Shot Header Operators

- Safety First Certification for Steel Shot Header Operators

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Shot Header Operator

- Emphasize your technical skills and experience in operating and maintaining steel shot header machinery.

- Highlight your ability to monitor and control process parameters to achieve desired shot characteristics.

- Showcase your knowledge of safety protocols and quality standards in the manufacturing industry.

- Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate your impact.

Essential Experience Highlights for a Strong Steel Shot Header Operator Resume

- Established and maintained a safe and efficient work environment.

- Executed daily maintenance and troubleshooting to ensure optimal operation of steel shot header equipment.

- Monitored and controlled process parameters to achieve desired shot characteristics, such as size, shape, and hardness.

- Loaded and unloaded raw materials (steel wire, alloying agents) into the header machine.

- Operated shot header machinery to produce steel shot products of various sizes and specifications.

- Collaborated with quality control personnel to ensure compliance with industry standards and customer requirements.

- Maintained accurate records of production data, equipment maintenance, and raw material usage.

Frequently Asked Questions (FAQ’s) For Steel Shot Header Operator

What is the primary role of a Steel Shot Header Operator?

Steel Shot Header Operators are responsible for operating and maintaining steel shot header machinery to produce steel shot products of various sizes and specifications.

What are the essential skills and qualifications for a Steel Shot Header Operator?

Essential skills and qualifications include technical proficiency in operating steel shot header machinery, knowledge of process parameters and quality standards, and a strong commitment to safety.

What are the career prospects for a Steel Shot Header Operator?

Steel Shot Header Operators can advance to supervisory or management roles within the manufacturing industry. With additional training and experience, they can also pursue opportunities in quality control, process engineering, or production management.

How can I prepare for an interview as a Steel Shot Header Operator?

Prior to an interview, research the company and the specific role, practice answering common interview questions, and review safety protocols and quality standards related to the manufacturing industry.

How can I stay updated on the latest advancements in steel shot header technology?

Attend industry conferences, read trade publications, and connect with professionals in the field to stay informed about the latest advancements and best practices in steel shot header operations.

What are the key challenges faced by Steel Shot Header Operators?

Some key challenges faced by Steel Shot Header Operators include ensuring product quality, maintaining equipment efficiency, and adhering to safety regulations in a demanding manufacturing environment.