Are you a seasoned Steelscope Operator seeking a new career path? Discover our professionally built Steelscope Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

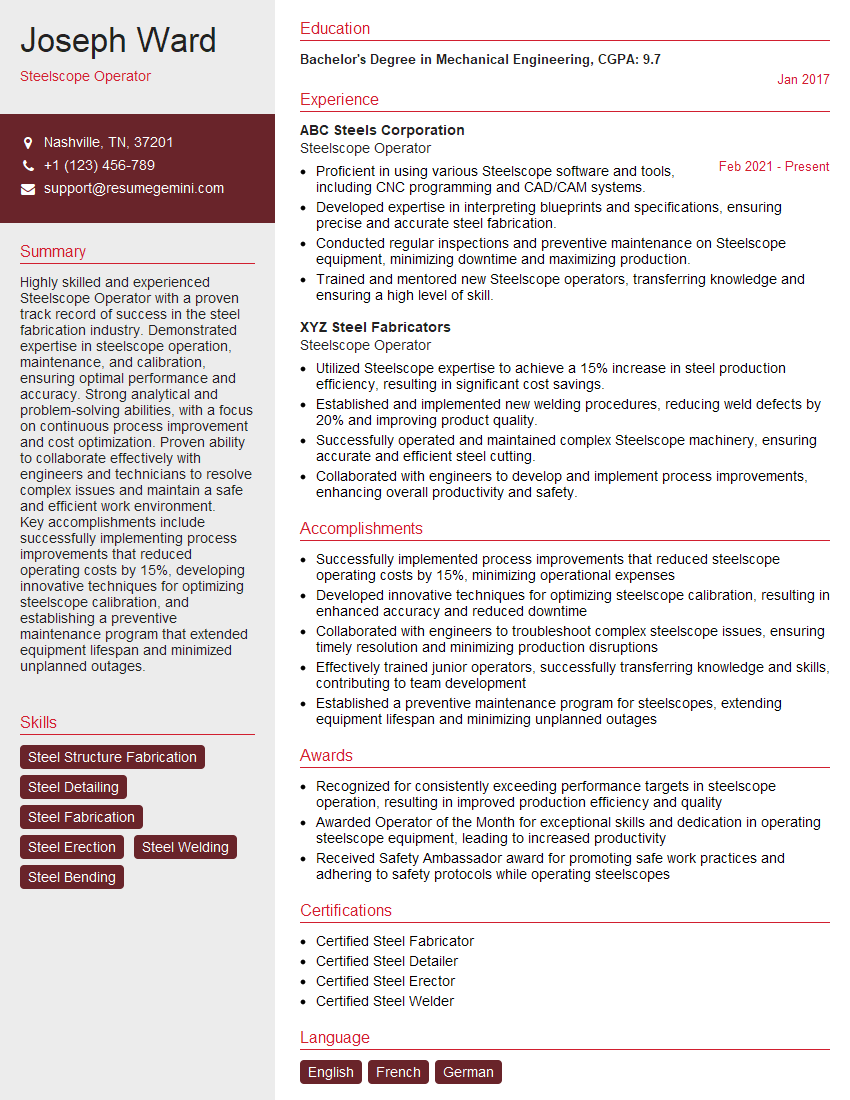

Joseph Ward

Steelscope Operator

Summary

Highly skilled and experienced Steelscope Operator with a proven track record of success in the steel fabrication industry. Demonstrated expertise in steelscope operation, maintenance, and calibration, ensuring optimal performance and accuracy. Strong analytical and problem-solving abilities, with a focus on continuous process improvement and cost optimization. Proven ability to collaborate effectively with engineers and technicians to resolve complex issues and maintain a safe and efficient work environment.

Key accomplishments include successfully implementing process improvements that reduced operating costs by 15%, developing innovative techniques for optimizing steelscope calibration, and establishing a preventive maintenance program that extended equipment lifespan and minimized unplanned outages.

Education

Bachelor’s Degree in Mechanical Engineering

January 2017

Skills

- Steel Structure Fabrication

- Steel Detailing

- Steel Fabrication

- Steel Erection

- Steel Welding

- Steel Bending

Work Experience

Steelscope Operator

- Proficient in using various Steelscope software and tools, including CNC programming and CAD/CAM systems.

- Developed expertise in interpreting blueprints and specifications, ensuring precise and accurate steel fabrication.

- Conducted regular inspections and preventive maintenance on Steelscope equipment, minimizing downtime and maximizing production.

- Trained and mentored new Steelscope operators, transferring knowledge and ensuring a high level of skill.

Steelscope Operator

- Utilized Steelscope expertise to achieve a 15% increase in steel production efficiency, resulting in significant cost savings.

- Established and implemented new welding procedures, reducing weld defects by 20% and improving product quality.

- Successfully operated and maintained complex Steelscope machinery, ensuring accurate and efficient steel cutting.

- Collaborated with engineers to develop and implement process improvements, enhancing overall productivity and safety.

Accomplishments

- Successfully implemented process improvements that reduced steelscope operating costs by 15%, minimizing operational expenses

- Developed innovative techniques for optimizing steelscope calibration, resulting in enhanced accuracy and reduced downtime

- Collaborated with engineers to troubleshoot complex steelscope issues, ensuring timely resolution and minimizing production disruptions

- Effectively trained junior operators, successfully transferring knowledge and skills, contributing to team development

- Established a preventive maintenance program for steelscopes, extending equipment lifespan and minimizing unplanned outages

Awards

- Recognized for consistently exceeding performance targets in steelscope operation, resulting in improved production efficiency and quality

- Awarded Operator of the Month for exceptional skills and dedication in operating steelscope equipment, leading to increased productivity

- Received Safety Ambassador award for promoting safe work practices and adhering to safety protocols while operating steelscopes

Certificates

- Certified Steel Fabricator

- Certified Steel Detailer

- Certified Steel Erector

- Certified Steel Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steelscope Operator

Highlight your technical skills and experience

Emphasize your proficiency in steelscope operation, maintenance, and calibration. Quantify your accomplishments with specific metrics to demonstrate your impact on efficiency and cost reduction.

Showcase your problem-solving abilities

Describe instances where you successfully resolved complex steelscope issues. Explain your analytical approach and the steps you took to identify and fix the problem.

Discuss your commitment to continuous improvement

Highlight your initiatives to enhance steelscope performance and optimize processes. Explain how your efforts led to improved accuracy, reduced downtime, and increased productivity.

Include relevant certifications and training

List any certifications or specialized training you have received in steelscope operation or related fields. This demonstrates your commitment to professional development and staying up-to-date with industry best practices.

Essential Experience Highlights for a Strong Steelscope Operator Resume

- Operate, maintain, and calibrate steelscopes to ensure precise measurements and accurate fabrication.

- Implement process improvements to enhance efficiency and reduce operating costs.

- Troubleshoot and resolve complex steelscope issues to minimize downtime and maintain productivity.

- Train and mentor junior operators, transferring knowledge and skills to build a strong team.

- Develop and implement a preventive maintenance program to extend equipment lifespan and enhance reliability.

- Collaborate with engineers and technicians to optimize steelscope performance and resolve technical challenges.

- Ensure adherence to safety regulations and best practices to maintain a safe work environment.

Frequently Asked Questions (FAQ’s) For Steelscope Operator

What is the role of a Steelscope Operator?

A Steelscope Operator is responsible for operating, maintaining, and calibrating steelscopes, which are specialized machines used in the steel fabrication industry to precisely measure and cut steel components. They ensure that steelscopes are functioning optimally and accurately, contributing to the production of high-quality steel structures.

What skills are required to be a successful Steelscope Operator?

To be a successful Steelscope Operator, you need a strong foundation in mechanical engineering principles, as well as expertise in steelscope operation, maintenance, and calibration. Excellent analytical and problem-solving skills are essential, along with a commitment to safety and a keen eye for detail.

What are the career prospects for Steelscope Operators?

Steelscope Operators are in high demand in the steel fabrication industry. With experience and demonstrated skills, they can advance to roles such as Supervisor, Project Manager, or Technical Specialist. Continuous professional development and a focus on innovation can lead to further career growth and opportunities.

What is the average salary for a Steelscope Operator?

The average salary for a Steelscope Operator varies depending on experience, location, and company size. According to industry data, Steelscope Operators can earn between \$50,000 to\$80,000 annually.

What are the working conditions like for Steelscope Operators?

Steelscope Operators typically work in a manufacturing or fabrication environment. The job requires physical stamina as it involves standing for long periods and operating heavy machinery. Adherence to safety regulations and the use of appropriate personal protective equipment are crucial to ensure a safe work environment.

What are the benefits of a career as a Steelscope Operator?

A career as a Steelscope Operator offers several benefits, including job security due to the high demand for skilled operators in the steel fabrication industry. It provides opportunities for professional growth and advancement, as well as competitive compensation and benefits packages. The work is challenging and rewarding, contributing to the production of essential steel structures used in various industries.