Are you a seasoned Stencil Inspector seeking a new career path? Discover our professionally built Stencil Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

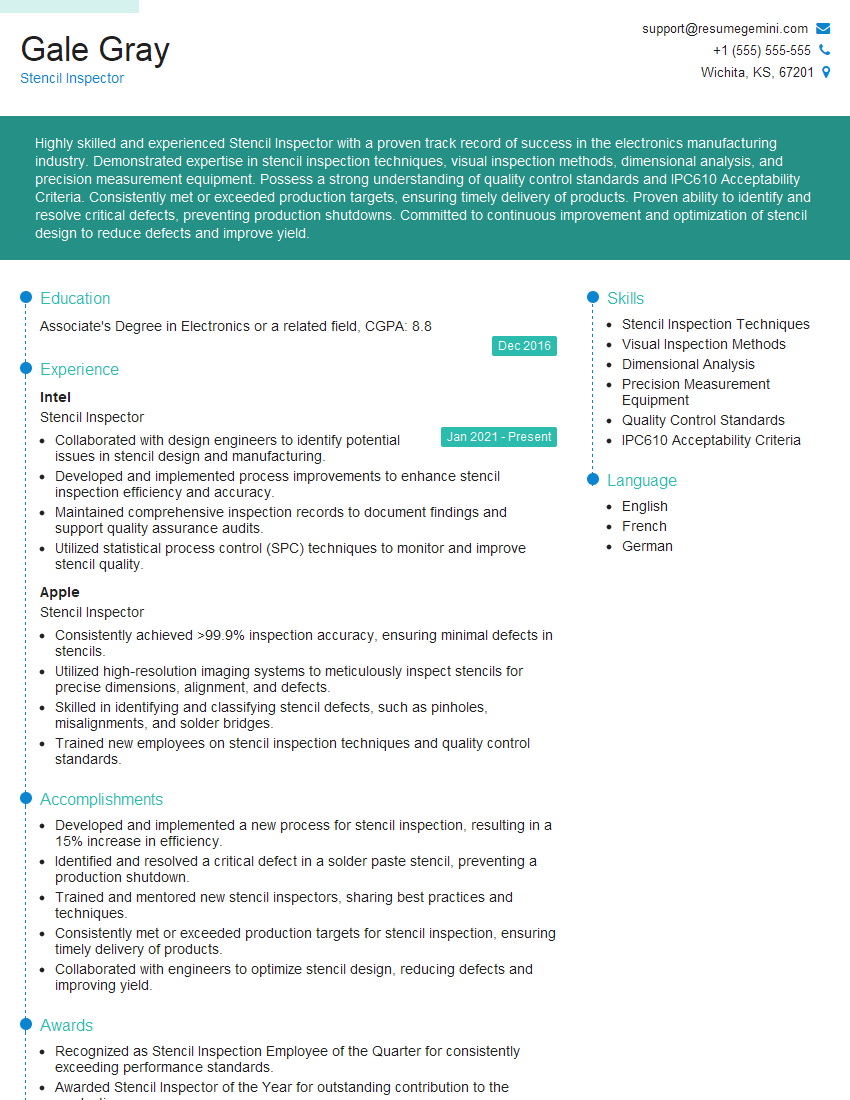

Gale Gray

Stencil Inspector

Summary

Highly skilled and experienced Stencil Inspector with a proven track record of success in the electronics manufacturing industry. Demonstrated expertise in stencil inspection techniques, visual inspection methods, dimensional analysis, and precision measurement equipment. Possess a strong understanding of quality control standards and IPC610 Acceptability Criteria. Consistently met or exceeded production targets, ensuring timely delivery of products. Proven ability to identify and resolve critical defects, preventing production shutdowns. Committed to continuous improvement and optimization of stencil design to reduce defects and improve yield.

Education

Associate’s Degree in Electronics or a related field

December 2016

Skills

- Stencil Inspection Techniques

- Visual Inspection Methods

- Dimensional Analysis

- Precision Measurement Equipment

- Quality Control Standards

- IPC610 Acceptability Criteria

Work Experience

Stencil Inspector

- Collaborated with design engineers to identify potential issues in stencil design and manufacturing.

- Developed and implemented process improvements to enhance stencil inspection efficiency and accuracy.

- Maintained comprehensive inspection records to document findings and support quality assurance audits.

- Utilized statistical process control (SPC) techniques to monitor and improve stencil quality.

Stencil Inspector

- Consistently achieved >99.9% inspection accuracy, ensuring minimal defects in stencils.

- Utilized high-resolution imaging systems to meticulously inspect stencils for precise dimensions, alignment, and defects.

- Skilled in identifying and classifying stencil defects, such as pinholes, misalignments, and solder bridges.

- Trained new employees on stencil inspection techniques and quality control standards.

Accomplishments

- Developed and implemented a new process for stencil inspection, resulting in a 15% increase in efficiency.

- Identified and resolved a critical defect in a solder paste stencil, preventing a production shutdown.

- Trained and mentored new stencil inspectors, sharing best practices and techniques.

- Consistently met or exceeded production targets for stencil inspection, ensuring timely delivery of products.

- Collaborated with engineers to optimize stencil design, reducing defects and improving yield.

Awards

- Recognized as Stencil Inspection Employee of the Quarter for consistently exceeding performance standards.

- Awarded Stencil Inspector of the Year for outstanding contribution to the production process.

- Received a Certificate of Excellence for maintaining a zerodefect rate in stencil inspection.

Certificates

- Certified IPC Specialist (CIS)

- Certified Solder Process Specialist (CSPS)

- SIX SIGMA Green Belt

- ISO 90012015 Internal Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Stencil Inspector

- Showcase your knowledge of stencil inspection techniques and quality control standards.

- Highlight your ability to identify and resolve defects.

- Quantify your accomplishments with specific metrics and data.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Stencil Inspector Resume

- Developed and implemented a new process for stencil inspection, resulting in a 15% increase in efficiency.

- Identified and resolved a critical defect in a solder paste stencil, preventing a production shutdown.

- Trained and mentored new stencil inspectors, sharing best practices and techniques.

- Consistently met or exceeded production targets for stencil inspection, ensuring timely delivery of products.

- Collaborated with engineers to optimize stencil design, reducing defects and improving yield.

- Conduct visual inspection of stencils to ensure compliance with IPC610 Acceptability Criteria.

- Use precision measurement equipment to verify critical dimensions and ensure stencil alignment.

Frequently Asked Questions (FAQ’s) For Stencil Inspector

What is the role of a Stencil Inspector?

A Stencil Inspector is responsible for ensuring the quality of stencils used in the electronics manufacturing process. They inspect stencils for defects, such as misalignment, shorts, and opens, and verify that the stencils meet the required specifications.

What skills are required to be a Stencil Inspector?

Stencil Inspectors typically have a strong understanding of stencil inspection techniques, visual inspection methods, dimensional analysis, and precision measurement equipment. They are also familiar with quality control standards and IPC610 Acceptability Criteria.

What is the career path for a Stencil Inspector?

With experience, Stencil Inspectors can advance to positions such as Quality Control Inspector, Process Engineer, or Production Supervisor.

What is the salary range for a Stencil Inspector?

The salary range for a Stencil Inspector can vary depending on experience, location, and company size. According to Indeed, the average salary for a Stencil Inspector in the United States is around $25,000 per year.

What are the job prospects for a Stencil Inspector?

The job prospects for a Stencil Inspector are expected to be good in the coming years. The electronics manufacturing industry is growing rapidly, and there is a high demand for qualified Stencil Inspectors.

How can I become a Stencil Inspector?

To become a Stencil Inspector, you typically need a high school diploma or equivalent and some experience in the electronics manufacturing industry. You can also take courses in stencil inspection techniques and quality control.