Are you a seasoned Stitching Machine Setter seeking a new career path? Discover our professionally built Stitching Machine Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

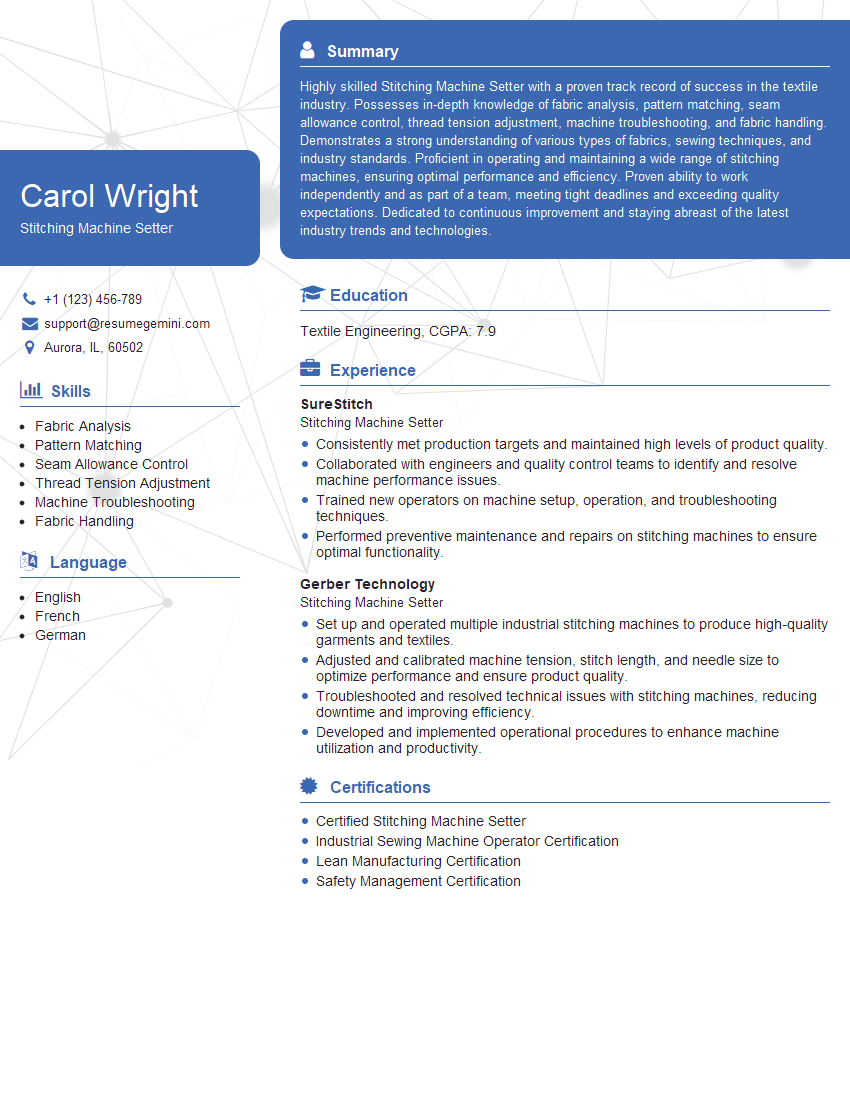

Carol Wright

Stitching Machine Setter

Summary

Highly skilled Stitching Machine Setter with a proven track record of success in the textile industry. Possesses in-depth knowledge of fabric analysis, pattern matching, seam allowance control, thread tension adjustment, machine troubleshooting, and fabric handling. Demonstrates a strong understanding of various types of fabrics, sewing techniques, and industry standards. Proficient in operating and maintaining a wide range of stitching machines, ensuring optimal performance and efficiency. Proven ability to work independently and as part of a team, meeting tight deadlines and exceeding quality expectations. Dedicated to continuous improvement and staying abreast of the latest industry trends and technologies.

Education

Textile Engineering

May 2015

Skills

- Fabric Analysis

- Pattern Matching

- Seam Allowance Control

- Thread Tension Adjustment

- Machine Troubleshooting

- Fabric Handling

Work Experience

Stitching Machine Setter

- Consistently met production targets and maintained high levels of product quality.

- Collaborated with engineers and quality control teams to identify and resolve machine performance issues.

- Trained new operators on machine setup, operation, and troubleshooting techniques.

- Performed preventive maintenance and repairs on stitching machines to ensure optimal functionality.

Stitching Machine Setter

- Set up and operated multiple industrial stitching machines to produce high-quality garments and textiles.

- Adjusted and calibrated machine tension, stitch length, and needle size to optimize performance and ensure product quality.

- Troubleshooted and resolved technical issues with stitching machines, reducing downtime and improving efficiency.

- Developed and implemented operational procedures to enhance machine utilization and productivity.

Certificates

- Certified Stitching Machine Setter

- Industrial Sewing Machine Operator Certification

- Lean Manufacturing Certification

- Safety Management Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Stitching Machine Setter

- Highlight your technical skills and expertise in fabric analysis, pattern matching, and machine troubleshooting

- Showcase your experience working with a variety of fabrics, sewing techniques, and stitching machines

- Emphasize your ability to work independently and as part of a team, meeting deadlines and exceeding quality expectations

- Include relevant certifications or training programs that demonstrate your commitment to professional development and industry best practices

- Showcase your knowledge of industry standards and regulations related to garment manufacturing

Essential Experience Highlights for a Strong Stitching Machine Setter Resume

- Analyze fabrics to determine appropriate stitching methods and machine settings

- Match patterns precisely to ensure accurate seam alignment and garment construction

- Control seam allowances to meet industry standards and prevent fabric distortion

- Adjust thread tension to optimize stitch quality and prevent thread breakage

- Troubleshoot and resolve machine malfunctions to maintain optimal production flow

- Handle fabrics with care to prevent damage and ensure garment quality

- Establish and maintain a clean and organized work area to promote efficiency and safety

Frequently Asked Questions (FAQ’s) For Stitching Machine Setter

What are the key skills required to be a successful Stitching Machine Setter?

The key skills required for a successful Stitching Machine Setter include fabric analysis, pattern matching, seam allowance control, thread tension adjustment, machine troubleshooting, and fabric handling.

What are the common challenges faced by Stitching Machine Setters?

Common challenges faced by Stitching Machine Setters include working with delicate fabrics, meeting tight deadlines, and maintaining consistent stitch quality.

What are the career advancement opportunities for Stitching Machine Setters?

Stitching Machine Setters with experience and expertise can advance to roles such as Production Supervisor, Quality Control Inspector, or Technical Support Specialist.

What is the average salary range for Stitching Machine Setters?

The average salary range for Stitching Machine Setters varies depending on experience, location, and industry, but typically falls between $15-$25 per hour.

What are the essential certifications for Stitching Machine Setters?

While not always required, certifications such as the Certified Production Technician (CPT) from the American Apparel & Footwear Association (AAFA) can enhance your credibility and job prospects.

What are the safety precautions that Stitching Machine Setters should follow?

Stitching Machine Setters should follow safety precautions such as wearing appropriate safety gear, keeping work areas clean and organized, and being aware of potential hazards such as sharp needles and moving machinery.