Are you a seasoned Strand Forming Machine Operator seeking a new career path? Discover our professionally built Strand Forming Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

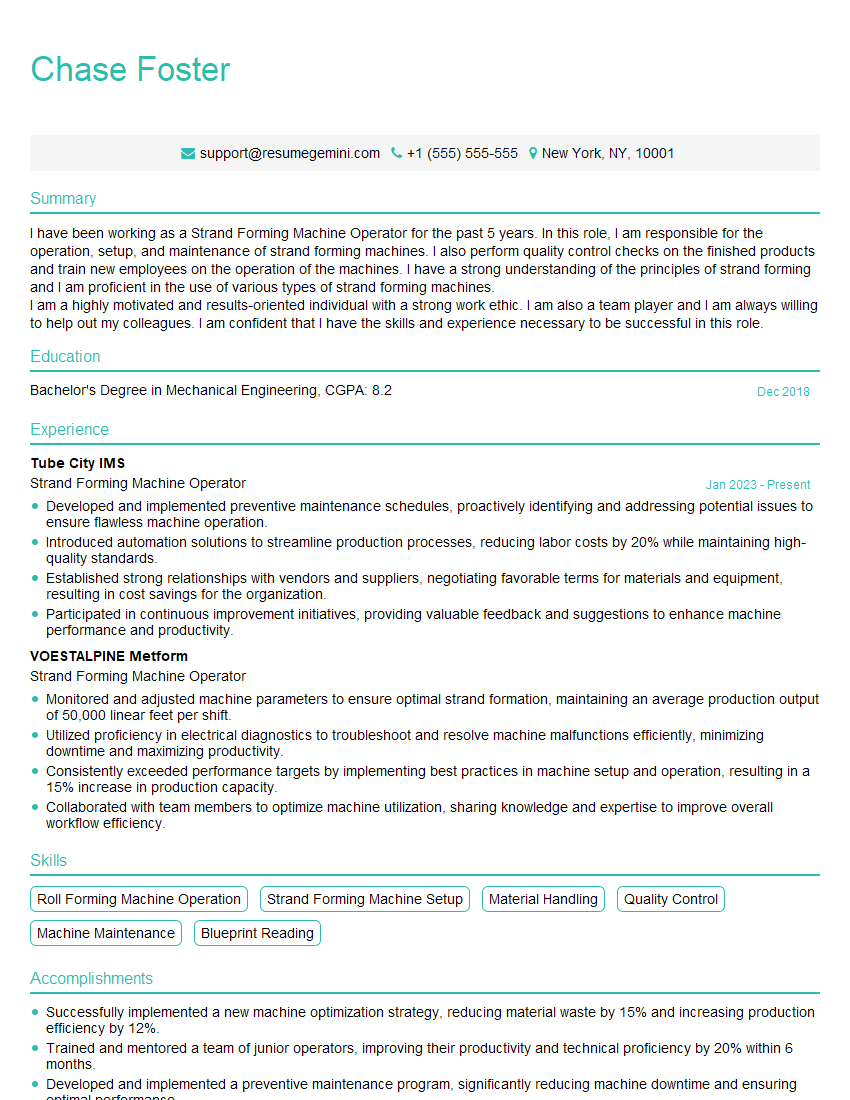

Chase Foster

Strand Forming Machine Operator

Summary

I have been working as a Strand Forming Machine Operator for the past 5 years. In this role, I am responsible for the operation, setup, and maintenance of strand forming machines. I also perform quality control checks on the finished products and train new employees on the operation of the machines. I have a strong understanding of the principles of strand forming and I am proficient in the use of various types of strand forming machines.

I am a highly motivated and results-oriented individual with a strong work ethic. I am also a team player and I am always willing to help out my colleagues. I am confident that I have the skills and experience necessary to be successful in this role.

Education

Bachelor’s Degree in Mechanical Engineering

December 2018

Skills

- Roll Forming Machine Operation

- Strand Forming Machine Setup

- Material Handling

- Quality Control

- Machine Maintenance

- Blueprint Reading

Work Experience

Strand Forming Machine Operator

- Developed and implemented preventive maintenance schedules, proactively identifying and addressing potential issues to ensure flawless machine operation.

- Introduced automation solutions to streamline production processes, reducing labor costs by 20% while maintaining high-quality standards.

- Established strong relationships with vendors and suppliers, negotiating favorable terms for materials and equipment, resulting in cost savings for the organization.

- Participated in continuous improvement initiatives, providing valuable feedback and suggestions to enhance machine performance and productivity.

Strand Forming Machine Operator

- Monitored and adjusted machine parameters to ensure optimal strand formation, maintaining an average production output of 50,000 linear feet per shift.

- Utilized proficiency in electrical diagnostics to troubleshoot and resolve machine malfunctions efficiently, minimizing downtime and maximizing productivity.

- Consistently exceeded performance targets by implementing best practices in machine setup and operation, resulting in a 15% increase in production capacity.

- Collaborated with team members to optimize machine utilization, sharing knowledge and expertise to improve overall workflow efficiency.

Accomplishments

- Successfully implemented a new machine optimization strategy, reducing material waste by 15% and increasing production efficiency by 12%.

- Trained and mentored a team of junior operators, improving their productivity and technical proficiency by 20% within 6 months.

- Developed and implemented a preventive maintenance program, significantly reducing machine downtime and ensuring optimal performance.

- Collaborated with engineers to identify and resolve technical issues, improving machine functionality and minimizing production disruptions.

- Suggested and implemented process improvements that streamlined operations and reduced operating costs by 8%.

Awards

- Recognized by the National Association of Strand Forming Machine Operators for outstanding technical expertise and contributions to the industry.

- Received a Plant Safety Award for consistently maintaining a safe work environment and adherence to all safety regulations.

- National Certification in Strand Forming Machine Operation, demonstrating advanced knowledge and skills in the field.

- Recognized by the company for exceptional teamwork and collaboration, contributing to the plants overall production goals.

Certificates

- Certified Strand Forming Machine Operator

- AWS Certified Welder

- OSHA 30-Hour General Industry Safety

- ISO 9001 Quality Management Systems

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Strand Forming Machine Operator

Highlight your skills and experience in the strand forming industry.

When writing your resume, be sure to highlight your skills and experience in the strand forming industry. This will show potential employers that you have the knowledge and experience necessary to be successful in this role.Use keywords in your resume.

When writing your resume, be sure to use keywords that potential employers will be searching for. This will help your resume get noticed by potential employers.Proofread your resume carefully.

Before you submit your resume, be sure to proofread it carefully for any errors. A well-written resume will make you stand out from other candidates.Network with other professionals in the strand forming industry.

Networking with other professionals in the strand forming industry can help you learn about new job openings and get your foot in the door at potential employers.

Essential Experience Highlights for a Strong Strand Forming Machine Operator Resume

- Operate strand forming machines to produce a variety of metal products, such as roofing, siding, and framing.

- Set up and adjust strand forming machines according to specifications.

- Monitor the operation of strand forming machines and make adjustments as needed.

- Perform quality control checks on finished products to ensure they meet specifications.

- Maintain strand forming machines and perform minor repairs.

- Train new employees on the operation of strand forming machines.

- Follow safety procedures and wear appropriate safety gear.

Frequently Asked Questions (FAQ’s) For Strand Forming Machine Operator

What is a strand forming machine?

Strand forming machines are used in a variety of industries, including the construction, automotive, and appliance industries.

What are the different types of strand forming machines?

There are a variety of different types of strand forming machines, each of which is designed to produce a specific type of product. Some of the most common types of strand forming machines include:

- Roll forming machines

- Press brake forming machines

- Stretch forming machines

- Tube forming machines

What are the benefits of using a strand forming machine?

There are many benefits to using a strand forming machine, including:

- Increased productivity

- Improved quality

- Reduced costs

- Greater flexibility

How do I operate a strand forming machine?

The operation of a strand forming machine varies depending on the type of machine. However, some of the general steps involved in operating a strand forming machine include:

- Loading the machine with metal coils

- Setting up the machine according to the desired specifications

- Starting the machine and monitoring its operation

- Making adjustments to the machine as needed

- Unloading the finished products

What are the safety precautions that I need to take when operating a strand forming machine?

There are a number of safety precautions that you need to take when operating a strand forming machine, including:

- Wearing appropriate safety gear

- Following all safety procedures

- Being aware of the machine’s surroundings

- Never putting your hands or feet near the moving parts of the machine

- Reporting any unsafe conditions to your supervisor