Are you a seasoned Strip Cutter seeking a new career path? Discover our professionally built Strip Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

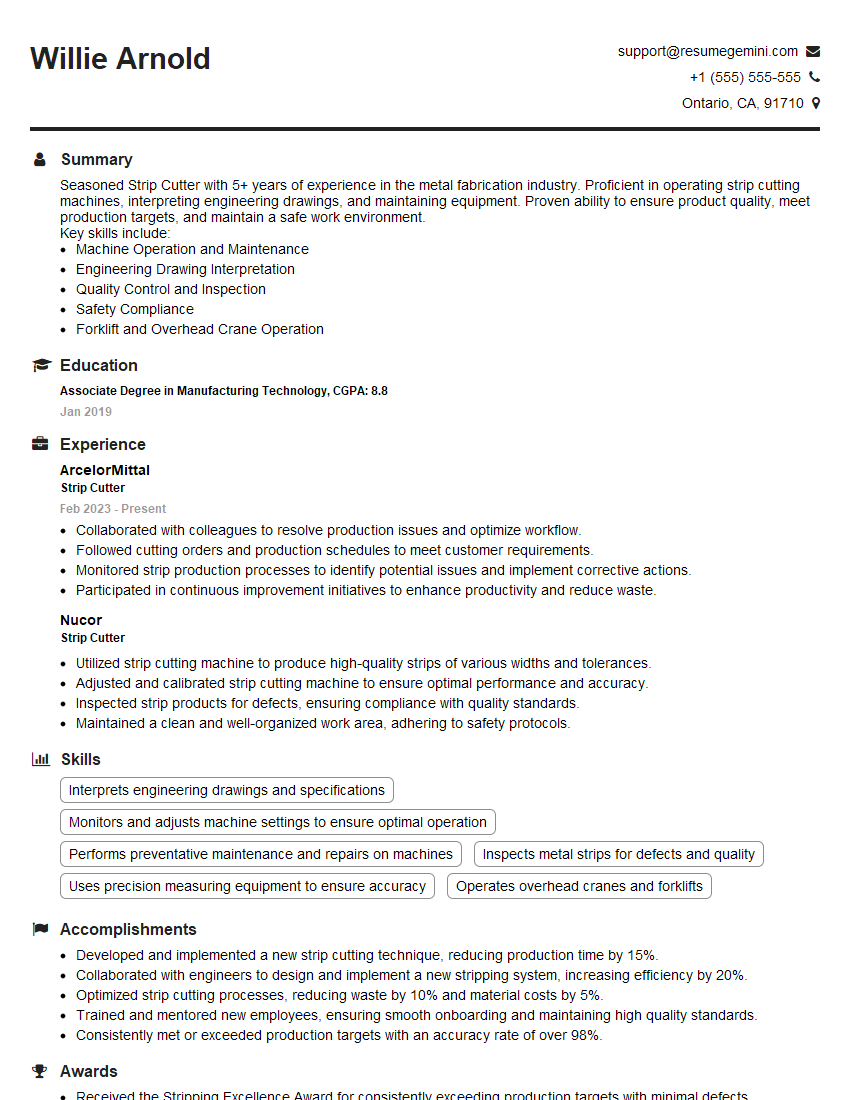

Willie Arnold

Strip Cutter

Summary

Seasoned Strip Cutter with 5+ years of experience in the metal fabrication industry. Proficient in operating strip cutting machines, interpreting engineering drawings, and maintaining equipment. Proven ability to ensure product quality, meet production targets, and maintain a safe work environment.

Key skills include:

- Machine Operation and Maintenance

- Engineering Drawing Interpretation

- Quality Control and Inspection

- Safety Compliance

- Forklift and Overhead Crane Operation

Education

Associate Degree in Manufacturing Technology

January 2019

Skills

- Interprets engineering drawings and specifications

- Monitors and adjusts machine settings to ensure optimal operation

- Performs preventative maintenance and repairs on machines

- Inspects metal strips for defects and quality

- Uses precision measuring equipment to ensure accuracy

- Operates overhead cranes and forklifts

Work Experience

Strip Cutter

- Collaborated with colleagues to resolve production issues and optimize workflow.

- Followed cutting orders and production schedules to meet customer requirements.

- Monitored strip production processes to identify potential issues and implement corrective actions.

- Participated in continuous improvement initiatives to enhance productivity and reduce waste.

Strip Cutter

- Utilized strip cutting machine to produce high-quality strips of various widths and tolerances.

- Adjusted and calibrated strip cutting machine to ensure optimal performance and accuracy.

- Inspected strip products for defects, ensuring compliance with quality standards.

- Maintained a clean and well-organized work area, adhering to safety protocols.

Accomplishments

- Developed and implemented a new strip cutting technique, reducing production time by 15%.

- Collaborated with engineers to design and implement a new stripping system, increasing efficiency by 20%.

- Optimized strip cutting processes, reducing waste by 10% and material costs by 5%.

- Trained and mentored new employees, ensuring smooth onboarding and maintaining high quality standards.

- Consistently met or exceeded production targets with an accuracy rate of over 98%.

Awards

- Received the Stripping Excellence Award for consistently exceeding production targets with minimal defects.

- Recognized for achieving the highest customer satisfaction ratings in the stripping department.

- Won the Innovation Award for developing a new tool that simplified the strip cutting process.

- Received the Safety Excellence Award for maintaining an exceptional safety record.

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Strip Cutter

- Highlight your proficiency in operating strip cutting machines and experience in interpreting engineering drawings.

- Quantify your accomplishments with specific metrics, such as increased production efficiency or reduced waste.

- Showcase your knowledge of quality control procedures and your ability to identify and resolve defects.

- Emphasize your commitment to safety and your experience in operating heavy equipment.

Essential Experience Highlights for a Strong Strip Cutter Resume

- Interpreted engineering drawings and specifications to determine strip cutting parameters.

- Monitored and adjusted machine settings to optimize cutting efficiency and minimize waste.

- Performed preventative maintenance and repairs on cutting machines, ensuring smooth operation and minimizing downtime.

- Inspected metal strips for defects and quality, adhering to established standards.

- Used precision measuring equipment to ensure accurate cutting and maintain product specifications.

- Utilized overhead cranes and forklifts to transport materials safely and efficiently.

- Maintained a clean and organized work area, adhering to safety protocols.

Frequently Asked Questions (FAQ’s) For Strip Cutter

What is a Strip Cutter?

A Strip Cutter is a machine operator responsible for cutting metal strips to specified dimensions using specialized cutting machines.

What are the key skills required for a Strip Cutter?

Key skills include machine operation, engineering drawing interpretation, quality control, safety compliance, and the ability to operate forklifts and overhead cranes.

What industries employ Strip Cutters?

Strip Cutters are employed in various industries that utilize metal strips, such as automotive, construction, and manufacturing.

What are the career advancement opportunities for a Strip Cutter?

With experience and additional training, Strip Cutters can advance to positions such as Machine Supervisor, Quality Inspector, or Production Manager.

What is the average salary for a Strip Cutter?

The average salary for a Strip Cutter varies depending on experience, location, and industry, but typically ranges from $25,000 to $50,000 per year.

What are the working conditions like for a Strip Cutter?

Strip Cutters typically work in industrial settings, operating machinery and handling metal strips. They may be exposed to noise, dust, and heavy lifting.

What are the educational requirements for a Strip Cutter?

While formal education is not always required, employers often prefer candidates with an associate degree in manufacturing technology or a related field.

What are the safety precautions that Strip Cutters must follow?

Strip Cutters must follow strict safety protocols to prevent accidents, including proper machine operation, wearing appropriate personal protective equipment, and maintaining a clean and organized work area.