Are you a seasoned Strip Metal Punch and Straightener Operator seeking a new career path? Discover our professionally built Strip Metal Punch and Straightener Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

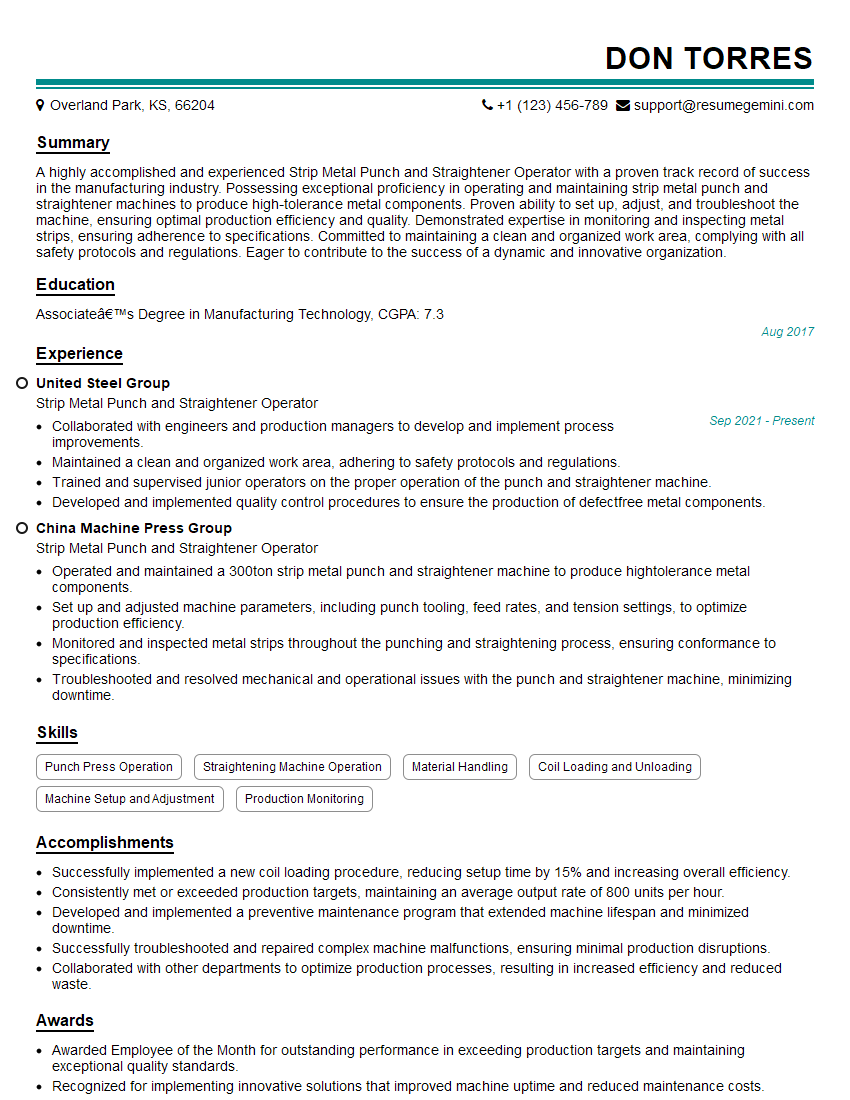

Don Torres

Strip Metal Punch and Straightener Operator

Summary

A highly accomplished and experienced Strip Metal Punch and Straightener Operator with a proven track record of success in the manufacturing industry. Possessing exceptional proficiency in operating and maintaining strip metal punch and straightener machines to produce high-tolerance metal components. Proven ability to set up, adjust, and troubleshoot the machine, ensuring optimal production efficiency and quality. Demonstrated expertise in monitoring and inspecting metal strips, ensuring adherence to specifications. Committed to maintaining a clean and organized work area, complying with all safety protocols and regulations. Eager to contribute to the success of a dynamic and innovative organization.

Education

Associate’s Degree in Manufacturing Technology

August 2017

Skills

- Punch Press Operation

- Straightening Machine Operation

- Material Handling

- Coil Loading and Unloading

- Machine Setup and Adjustment

- Production Monitoring

Work Experience

Strip Metal Punch and Straightener Operator

- Collaborated with engineers and production managers to develop and implement process improvements.

- Maintained a clean and organized work area, adhering to safety protocols and regulations.

- Trained and supervised junior operators on the proper operation of the punch and straightener machine.

- Developed and implemented quality control procedures to ensure the production of defectfree metal components.

Strip Metal Punch and Straightener Operator

- Operated and maintained a 300ton strip metal punch and straightener machine to produce hightolerance metal components.

- Set up and adjusted machine parameters, including punch tooling, feed rates, and tension settings, to optimize production efficiency.

- Monitored and inspected metal strips throughout the punching and straightening process, ensuring conformance to specifications.

- Troubleshooted and resolved mechanical and operational issues with the punch and straightener machine, minimizing downtime.

Accomplishments

- Successfully implemented a new coil loading procedure, reducing setup time by 15% and increasing overall efficiency.

- Consistently met or exceeded production targets, maintaining an average output rate of 800 units per hour.

- Developed and implemented a preventive maintenance program that extended machine lifespan and minimized downtime.

- Successfully troubleshooted and repaired complex machine malfunctions, ensuring minimal production disruptions.

- Collaborated with other departments to optimize production processes, resulting in increased efficiency and reduced waste.

Awards

- Awarded Employee of the Month for outstanding performance in exceeding production targets and maintaining exceptional quality standards.

- Recognized for implementing innovative solutions that improved machine uptime and reduced maintenance costs.

- Received a Safety Excellence Award for maintaining a spotless safety record and adhering to all safety protocols.

- Nominated for a Top Performer award for exceptional productivity and dedication to the job.

Certificates

- Certified Punch Press Operator

- Certified Straightening Machine Operator

- OSHA Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Strip Metal Punch and Straightener Operator

- Highlight your technical skills and experience in operating and maintaining strip metal punch and straightener machines.

- Demonstrate your understanding of the production process and your ability to optimize machine performance.

- Showcase your commitment to quality and your ability to identify and resolve potential issues.

- Quantify your achievements to provide concrete evidence of your contributions to the organization.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Strip Metal Punch and Straightener Operator Resume

- Setting up and adjusting machine parameters, including punch tooling, feed rates, and tension settings, to optimize production efficiency.

- Monitoring and inspecting metal strips throughout the punching and straightening process, ensuring conformance to specifications.

- Performing regular maintenance and troubleshooting to ensure that the strip metal punch and straightener machine is operating at optimal performance.

- Collaborating with engineers and production managers to develop and implement process improvements aimed at increasing efficiency and reducing downtime.

- Maintaining a clean and organized work area, adhering to all safety protocols and regulations.

- Training and supervising junior operators on the proper operation of the punch and straightener machine.

- Developing and implementing quality control procedures to ensure the production of defect-free metal components.

Frequently Asked Questions (FAQ’s) For Strip Metal Punch and Straightener Operator

What is the role of a Strip Metal Punch and Straightener Operator?

A Strip Metal Punch and Straightener Operator is responsible for operating and maintaining a strip metal punch and straightener machine to produce high-tolerance metal components. They set up and adjust machine parameters, monitor and inspect metal strips, troubleshoot and resolve mechanical and operational issues, and collaborate with engineers and production managers to develop and implement process improvements.

What skills are required to be a successful Strip Metal Punch and Straightener Operator?

To be a successful Strip Metal Punch and Straightener Operator, you need to have strong technical skills in operating and maintaining strip metal punch and straightener machines, as well as a good understanding of the production process. You should also be able to troubleshoot and resolve mechanical and operational issues, and have a commitment to quality.

What is the work environment of a Strip Metal Punch and Straightener Operator like?

Strip Metal Punch and Straightener Operators typically work in a manufacturing environment, operating and maintaining strip metal punch and straightener machines. They may be exposed to noise, dust, and other hazards, so it is important to wear appropriate safety gear.

What are the career prospects for Strip Metal Punch and Straightener Operators?

Strip Metal Punch and Straightener Operators can advance their careers by becoming supervisors or managers, or by specializing in a particular area of manufacturing. They may also choose to start their own businesses.

What is the job outlook for Strip Metal Punch and Straightener Operators?

The job outlook for Strip Metal Punch and Straightener Operators is expected to be good over the next few years, as the manufacturing industry continues to grow.