Are you a seasoned Supplier Quality Engineer (SQE) seeking a new career path? Discover our professionally built Supplier Quality Engineer (SQE) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

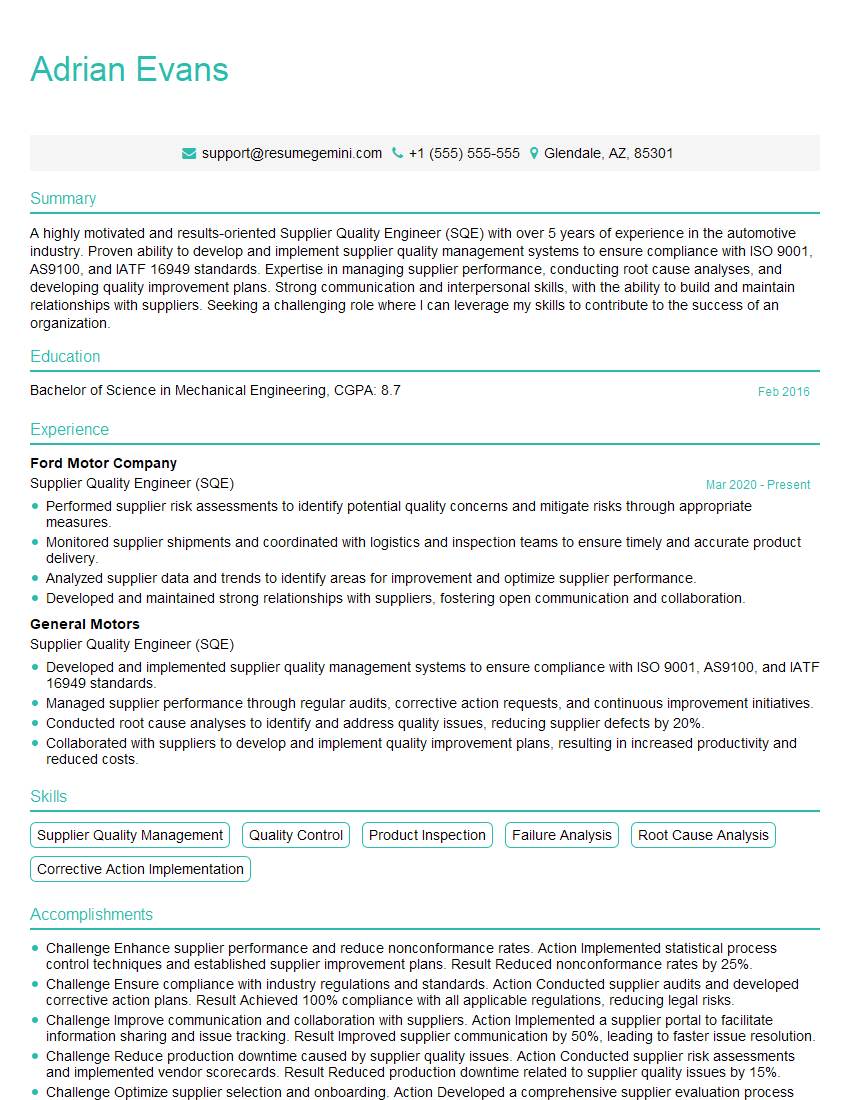

Adrian Evans

Supplier Quality Engineer (SQE)

Summary

A highly motivated and results-oriented Supplier Quality Engineer (SQE) with over 5 years of experience in the automotive industry. Proven ability to develop and implement supplier quality management systems to ensure compliance with ISO 9001, AS9100, and IATF 16949 standards. Expertise in managing supplier performance, conducting root cause analyses, and developing quality improvement plans. Strong communication and interpersonal skills, with the ability to build and maintain relationships with suppliers. Seeking a challenging role where I can leverage my skills to contribute to the success of an organization.

Education

Bachelor of Science in Mechanical Engineering

February 2016

Skills

- Supplier Quality Management

- Quality Control

- Product Inspection

- Failure Analysis

- Root Cause Analysis

- Corrective Action Implementation

Work Experience

Supplier Quality Engineer (SQE)

- Performed supplier risk assessments to identify potential quality concerns and mitigate risks through appropriate measures.

- Monitored supplier shipments and coordinated with logistics and inspection teams to ensure timely and accurate product delivery.

- Analyzed supplier data and trends to identify areas for improvement and optimize supplier performance.

- Developed and maintained strong relationships with suppliers, fostering open communication and collaboration.

Supplier Quality Engineer (SQE)

- Developed and implemented supplier quality management systems to ensure compliance with ISO 9001, AS9100, and IATF 16949 standards.

- Managed supplier performance through regular audits, corrective action requests, and continuous improvement initiatives.

- Conducted root cause analyses to identify and address quality issues, reducing supplier defects by 20%.

- Collaborated with suppliers to develop and implement quality improvement plans, resulting in increased productivity and reduced costs.

Accomplishments

- Challenge Enhance supplier performance and reduce nonconformance rates. Action Implemented statistical process control techniques and established supplier improvement plans. Result Reduced nonconformance rates by 25%.

- Challenge Ensure compliance with industry regulations and standards. Action Conducted supplier audits and developed corrective action plans. Result Achieved 100% compliance with all applicable regulations, reducing legal risks.

- Challenge Improve communication and collaboration with suppliers. Action Implemented a supplier portal to facilitate information sharing and issue tracking. Result Improved supplier communication by 50%, leading to faster issue resolution.

- Challenge Reduce production downtime caused by supplier quality issues. Action Conducted supplier risk assessments and implemented vendor scorecards. Result Reduced production downtime related to supplier quality issues by 15%.

- Challenge Optimize supplier selection and onboarding. Action Developed a comprehensive supplier evaluation process and training program. Result Increased supplier quality and reduced onboarding time by 20%.

Awards

- Supplier Quality Excellence Award for outstanding contributions to the improvement of supplier quality.

- Recognized with the Supplier of the Year Award for the exceptional quality of supplier deliveries.

- Received the Lean Six Sigma Green Belt Certification, demonstrating expertise in process improvement and quality control.

Certificates

- Certified Quality Engineer (CQE)

- Certified Six Sigma Black Belt (CSSBB)

- Certified Supplier Quality Professional (CSQP)

- Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Supplier Quality Engineer (SQE)

- Highlight your experience in developing and implementing supplier quality management systems.

- Provide specific examples of how you have improved supplier performance.

- Demonstrate your knowledge of quality standards and regulations in the automotive industry.

- Emphasize your problem-solving and analytical skills.

- Showcase your communication and interpersonal skills.

Essential Experience Highlights for a Strong Supplier Quality Engineer (SQE) Resume

- Developed and implemented supplier quality management systems to ensure compliance with ISO 9001, AS9100, and IATF 16949 standards.

- Managed supplier performance through regular audits, corrective action requests, and continuous improvement initiatives.

- Conducted root cause analyses to identify and address quality issues, reducing supplier defects by 20%.

- Collaborated with suppliers to develop and implement quality improvement plans, resulting in increased productivity and reduced costs.

- Performed supplier risk assessments to identify potential quality concerns and mitigate risks through appropriate measures.

- Monitored supplier shipments and coordinated with logistics and inspection teams to ensure timely and accurate product delivery.

- Analyzed supplier data and trends to identify areas for improvement and optimize supplier performance.

Frequently Asked Questions (FAQ’s) For Supplier Quality Engineer (SQE)

What is the role of a Supplier Quality Engineer (SQE)?

A Supplier Quality Engineer (SQE) is responsible for ensuring that the products and services provided by suppliers meet the quality standards of the organization. This involves developing and implementing supplier quality management systems, managing supplier performance, conducting root cause analyses, and collaborating with suppliers to improve quality.

What are the key skills required for a successful Supplier Quality Engineer (SQE)?

Key skills for a successful Supplier Quality Engineer (SQE) include knowledge of quality standards and regulations, experience in developing and implementing quality management systems, problem-solving and analytical skills, and strong communication and interpersonal skills.

What are the career prospects for a Supplier Quality Engineer (SQE)?

Supplier Quality Engineers (SQEs) can advance to roles such as Quality Manager, Supplier Quality Manager, or Six Sigma Black Belt. With experience and additional qualifications, SQEs can also move into leadership positions in quality assurance and quality control.

How can I become a certified Supplier Quality Engineer (SQE)?

There are several organizations that offer certification for Supplier Quality Engineers (SQEs). Some popular certifications include the Certified Supplier Quality Professional (CSQP) from the American Society for Quality (ASQ) and the Certified Quality Engineer (CQE) from the American Society for Quality (ASQ).

What is the average salary for a Supplier Quality Engineer (SQE)?

The average salary for a Supplier Quality Engineer (SQE) in the United States is around $85,000.

What are some of the benefits of working as a Supplier Quality Engineer (SQE)?

Some of the benefits of working as a Supplier Quality Engineer (SQE) include job security, opportunities for career advancement, and the satisfaction of knowing that you are helping to improve the quality of products and services.