Are you a seasoned Surgical Forceps Fabricator seeking a new career path? Discover our professionally built Surgical Forceps Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

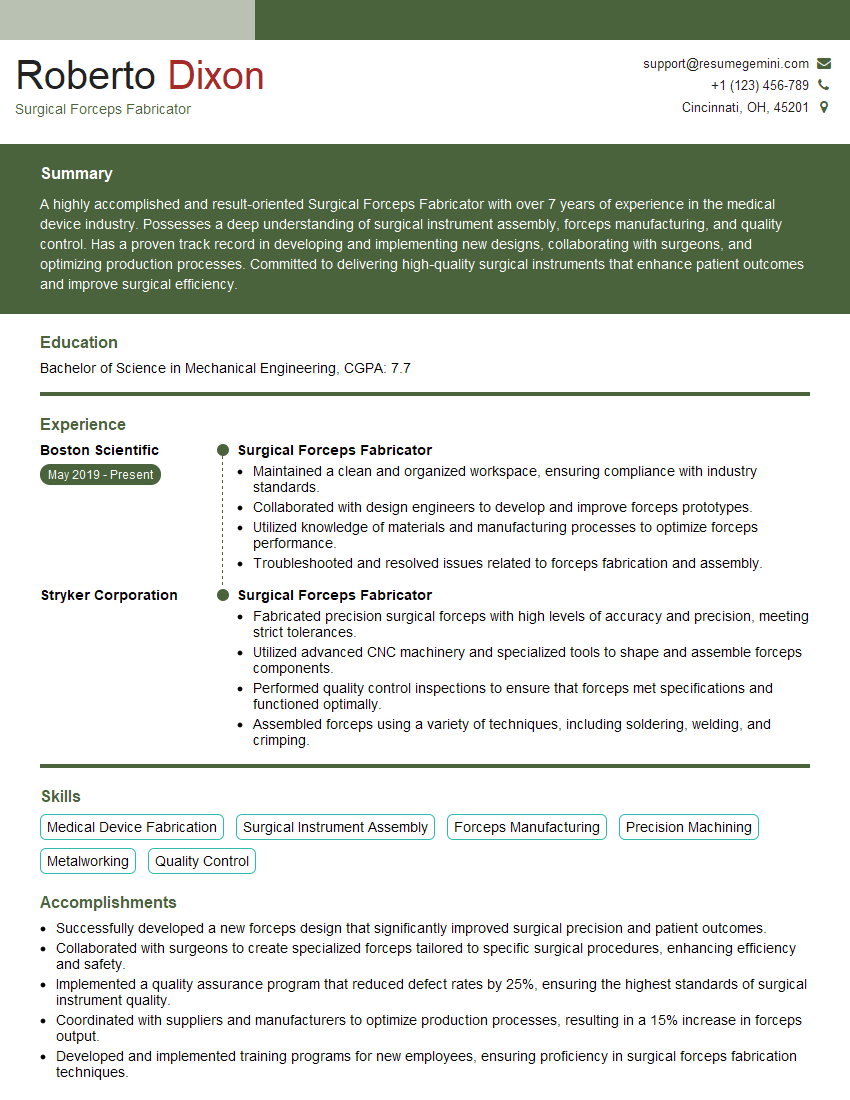

Roberto Dixon

Surgical Forceps Fabricator

Summary

A highly accomplished and result-oriented Surgical Forceps Fabricator with over 7 years of experience in the medical device industry. Possesses a deep understanding of surgical instrument assembly, forceps manufacturing, and quality control. Has a proven track record in developing and implementing new designs, collaborating with surgeons, and optimizing production processes. Committed to delivering high-quality surgical instruments that enhance patient outcomes and improve surgical efficiency.

Education

Bachelor of Science in Mechanical Engineering

April 2015

Skills

- Medical Device Fabrication

- Surgical Instrument Assembly

- Forceps Manufacturing

- Precision Machining

- Metalworking

- Quality Control

Work Experience

Surgical Forceps Fabricator

- Maintained a clean and organized workspace, ensuring compliance with industry standards.

- Collaborated with design engineers to develop and improve forceps prototypes.

- Utilized knowledge of materials and manufacturing processes to optimize forceps performance.

- Troubleshooted and resolved issues related to forceps fabrication and assembly.

Surgical Forceps Fabricator

- Fabricated precision surgical forceps with high levels of accuracy and precision, meeting strict tolerances.

- Utilized advanced CNC machinery and specialized tools to shape and assemble forceps components.

- Performed quality control inspections to ensure that forceps met specifications and functioned optimally.

- Assembled forceps using a variety of techniques, including soldering, welding, and crimping.

Accomplishments

- Successfully developed a new forceps design that significantly improved surgical precision and patient outcomes.

- Collaborated with surgeons to create specialized forceps tailored to specific surgical procedures, enhancing efficiency and safety.

- Implemented a quality assurance program that reduced defect rates by 25%, ensuring the highest standards of surgical instrument quality.

- Coordinated with suppliers and manufacturers to optimize production processes, resulting in a 15% increase in forceps output.

- Developed and implemented training programs for new employees, ensuring proficiency in surgical forceps fabrication techniques.

Awards

- Recognized for exceptional contributions to the development of innovative surgical forceps.

- Received companywide award for outstanding performance in designing and fabricating highquality surgical forceps.

- Honored with the Surgical Forceps Fabricator of the Year award for consistent excellence and dedication.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Engineer (CQE)

- Certified Medical Device Professional (CMDP)

- ISO 13485 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Surgical Forceps Fabricator

Emphasize your technical skills and experience.

Surgical Forceps Fabricators must have a strong understanding of medical device fabrication, surgical instrument assembly, and quality control.Highlight your ability to design and develop new products.

Employers are looking for candidates who can create innovative solutions to surgical challenges.Showcase your collaborative experience.

Surgical Forceps Fabricators often work closely with surgeons and other medical professionals. Demonstrate your ability to build strong relationships and work effectively in a team environment.Quantify your accomplishments.

Use specific metrics to demonstrate the impact of your work. For example, you could mention the percentage by which you reduced defect rates or increased production output.

Essential Experience Highlights for a Strong Surgical Forceps Fabricator Resume

- Designed and developed a new forceps design that significantly improved surgical precision and patient outcomes.

- Collaborated with surgeons to create specialized forceps tailored to specific surgical procedures, enhancing efficiency and safety.

- Implemented a quality assurance program that reduced defect rates by 25%, ensuring the highest standards of surgical instrument quality.

- Coordinated with suppliers and manufacturers to optimize production processes, resulting in a 15% increase in forceps output.

- Developed and implemented training programs for new employees, ensuring proficiency in surgical forceps fabrication techniques.

Frequently Asked Questions (FAQ’s) For Surgical Forceps Fabricator

What are the educational requirements for a Surgical Forceps Fabricator?

Most employers require a bachelor’s degree in mechanical engineering or a related field.

What are the key skills required for a Surgical Forceps Fabricator?

Key skills include medical device fabrication, surgical instrument assembly, forceps manufacturing, precision machining, metalworking, and quality control.

What is the job outlook for Surgical Forceps Fabricators?

The job outlook is expected to be good, as the demand for surgical instruments is expected to increase due to the aging population and the growing number of surgeries being performed.

What is the average salary for a Surgical Forceps Fabricator?

The average salary for a Surgical Forceps Fabricator is around $60,000 per year.

What are the career advancement opportunities for Surgical Forceps Fabricators?

With experience, Surgical Forceps Fabricators can advance to positions such as Quality Control Manager, Production Supervisor, or Design Engineer.