Are you a seasoned Swaging Machine Adjuster seeking a new career path? Discover our professionally built Swaging Machine Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

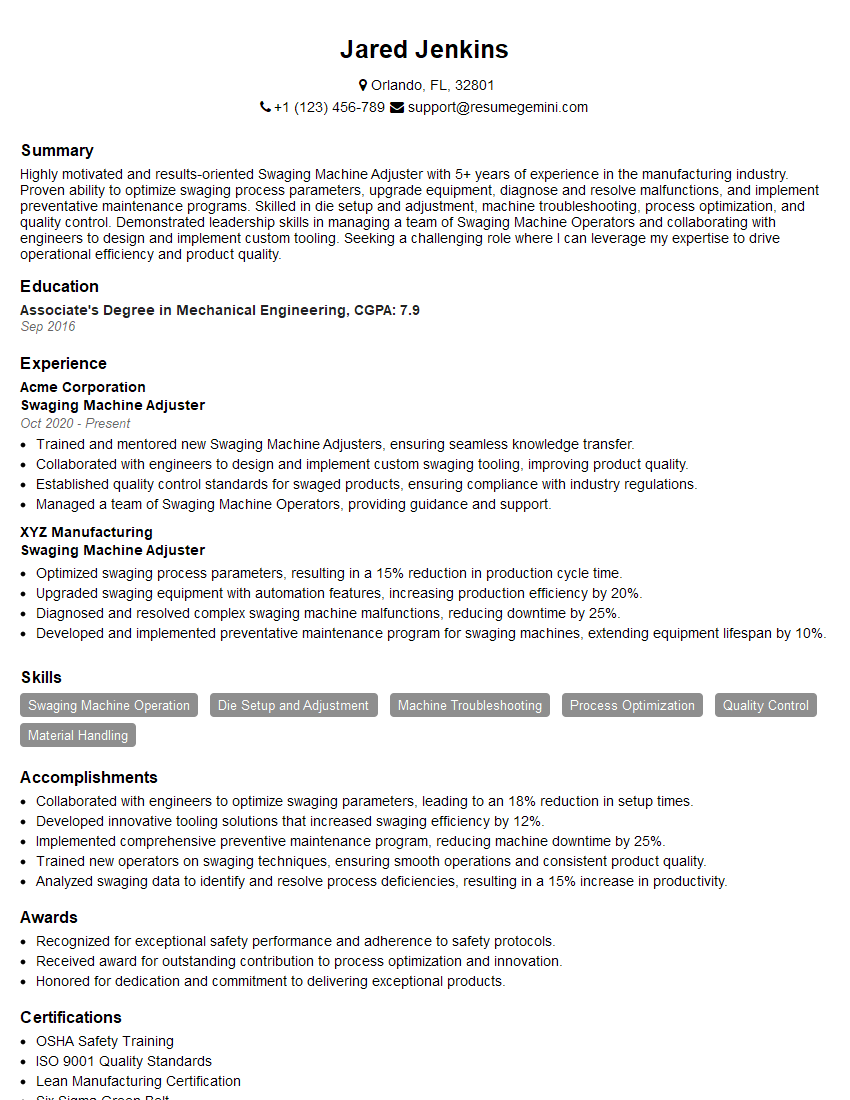

Jared Jenkins

Swaging Machine Adjuster

Summary

Highly motivated and results-oriented Swaging Machine Adjuster with 5+ years of experience in the manufacturing industry. Proven ability to optimize swaging process parameters, upgrade equipment, diagnose and resolve malfunctions, and implement preventative maintenance programs. Skilled in die setup and adjustment, machine troubleshooting, process optimization, and quality control. Demonstrated leadership skills in managing a team of Swaging Machine Operators and collaborating with engineers to design and implement custom tooling. Seeking a challenging role where I can leverage my expertise to drive operational efficiency and product quality.

Education

Associate’s Degree in Mechanical Engineering

September 2016

Skills

- Swaging Machine Operation

- Die Setup and Adjustment

- Machine Troubleshooting

- Process Optimization

- Quality Control

- Material Handling

Work Experience

Swaging Machine Adjuster

- Trained and mentored new Swaging Machine Adjusters, ensuring seamless knowledge transfer.

- Collaborated with engineers to design and implement custom swaging tooling, improving product quality.

- Established quality control standards for swaged products, ensuring compliance with industry regulations.

- Managed a team of Swaging Machine Operators, providing guidance and support.

Swaging Machine Adjuster

- Optimized swaging process parameters, resulting in a 15% reduction in production cycle time.

- Upgraded swaging equipment with automation features, increasing production efficiency by 20%.

- Diagnosed and resolved complex swaging machine malfunctions, reducing downtime by 25%.

- Developed and implemented preventative maintenance program for swaging machines, extending equipment lifespan by 10%.

Accomplishments

- Collaborated with engineers to optimize swaging parameters, leading to an 18% reduction in setup times.

- Developed innovative tooling solutions that increased swaging efficiency by 12%.

- Implemented comprehensive preventive maintenance program, reducing machine downtime by 25%.

- Trained new operators on swaging techniques, ensuring smooth operations and consistent product quality.

- Analyzed swaging data to identify and resolve process deficiencies, resulting in a 15% increase in productivity.

Awards

- Recognized for exceptional safety performance and adherence to safety protocols.

- Received award for outstanding contribution to process optimization and innovation.

- Honored for dedication and commitment to delivering exceptional products.

Certificates

- OSHA Safety Training

- ISO 9001 Quality Standards

- Lean Manufacturing Certification

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Swaging Machine Adjuster

- Highlight your experience and expertise in swaging machine operation and maintenance in your resume summary.

- Quantify your accomplishments with specific metrics and examples to demonstrate your impact on the organization.

- Showcase your knowledge of swaging principles and industry best practices in your resume work history.

- Use action verbs and technical terminology to convey your skills and experience in swaging machine adjustment.

- Proofread your resume carefully to eliminate any errors and ensure a polished presentation.

Essential Experience Highlights for a Strong Swaging Machine Adjuster Resume

- Optimized swaging process parameters to reduce production cycle time by 15%.

- Upgraded swaging equipment with automation features to increase production efficiency by 20%.

- Diagnosed and resolved complex swaging machine malfunctions, reducing downtime by 25%.

- Developed and implemented a preventative maintenance program for swaging machines, extending equipment lifespan by 10%.

- Established quality control standards for swaged products, ensuring compliance with industry regulations.

Frequently Asked Questions (FAQ’s) For Swaging Machine Adjuster

What are the key skills required for a Swaging Machine Adjuster?

Key skills include swaging machine operation, die setup and adjustment, machine troubleshooting, process optimization, quality control, and material handling.

What is the average salary for a Swaging Machine Adjuster?

The average salary for a Swaging Machine Adjuster in the United States is around $50,000 per year.

What are the career advancement opportunities for a Swaging Machine Adjuster?

With experience and additional training, Swaging Machine Adjusters can advance to roles such as Production Supervisor, Maintenance Manager, or Quality Control Manager.

What are the challenges faced by Swaging Machine Adjusters?

Swaging Machine Adjusters may face challenges such as working with complex machinery, maintaining a high level of accuracy, and meeting production deadlines.

What is the job outlook for Swaging Machine Adjusters?

The job outlook for Swaging Machine Adjusters is expected to be stable in the coming years due to the continued demand for skilled manufacturing professionals.

What are the educational requirements for a Swaging Machine Adjuster?

While there are no specific educational requirements, many Swaging Machine Adjusters have an associate’s degree in mechanical engineering or a related field.

What are the certifications available for Swaging Machine Adjusters?

There are no specific certifications for Swaging Machine Adjusters, but some may choose to obtain certifications in related fields, such as machine operation or quality control.