Are you a seasoned Swaging Machine Operator seeking a new career path? Discover our professionally built Swaging Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

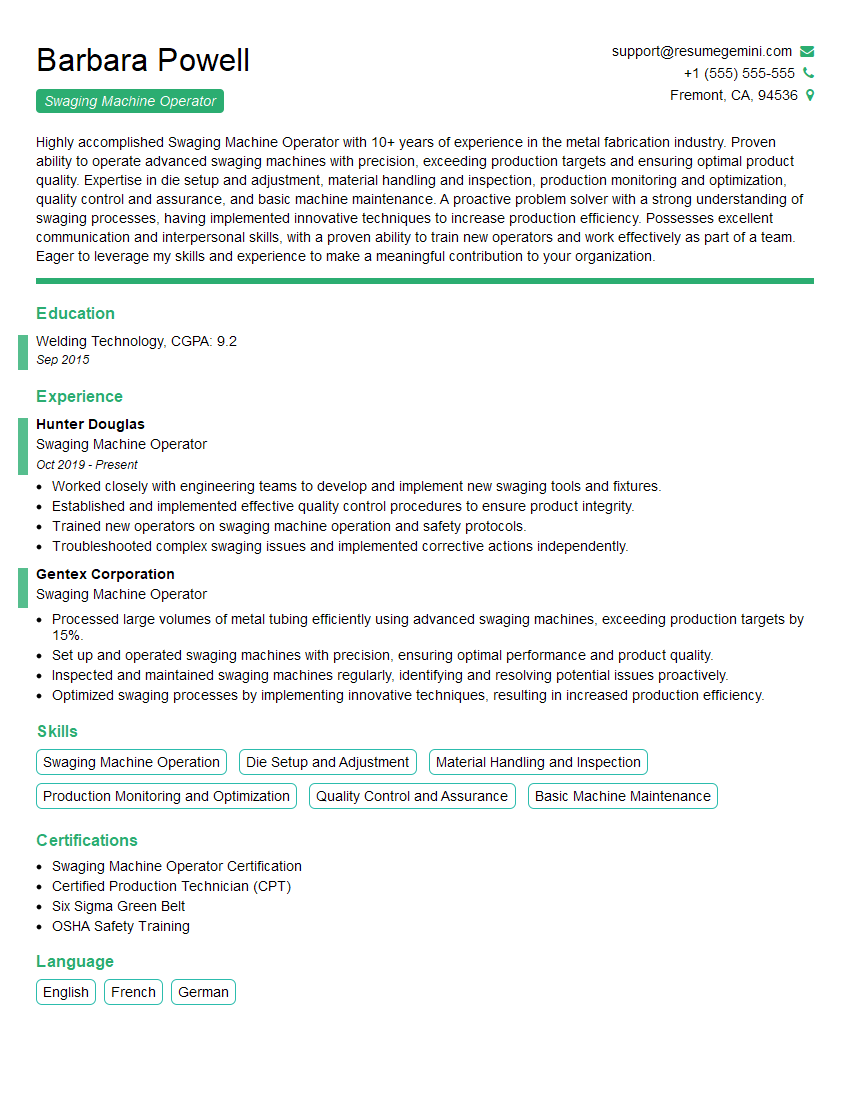

Barbara Powell

Swaging Machine Operator

Summary

Highly accomplished Swaging Machine Operator with 10+ years of experience in the metal fabrication industry. Proven ability to operate advanced swaging machines with precision, exceeding production targets and ensuring optimal product quality. Expertise in die setup and adjustment, material handling and inspection, production monitoring and optimization, quality control and assurance, and basic machine maintenance. A proactive problem solver with a strong understanding of swaging processes, having implemented innovative techniques to increase production efficiency. Possesses excellent communication and interpersonal skills, with a proven ability to train new operators and work effectively as part of a team. Eager to leverage my skills and experience to make a meaningful contribution to your organization.

Education

Welding Technology

September 2015

Skills

- Swaging Machine Operation

- Die Setup and Adjustment

- Material Handling and Inspection

- Production Monitoring and Optimization

- Quality Control and Assurance

- Basic Machine Maintenance

Work Experience

Swaging Machine Operator

- Worked closely with engineering teams to develop and implement new swaging tools and fixtures.

- Established and implemented effective quality control procedures to ensure product integrity.

- Trained new operators on swaging machine operation and safety protocols.

- Troubleshooted complex swaging issues and implemented corrective actions independently.

Swaging Machine Operator

- Processed large volumes of metal tubing efficiently using advanced swaging machines, exceeding production targets by 15%.

- Set up and operated swaging machines with precision, ensuring optimal performance and product quality.

- Inspected and maintained swaging machines regularly, identifying and resolving potential issues proactively.

- Optimized swaging processes by implementing innovative techniques, resulting in increased production efficiency.

Certificates

- Swaging Machine Operator Certification

- Certified Production Technician (CPT)

- Six Sigma Green Belt

- OSHA Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Swaging Machine Operator

- Highlight your experience and expertise in operating swaging machines, including specific models and their capabilities.

- Quantify your accomplishments by providing specific metrics and results, such as increased production efficiency or reduced downtime.

- Demonstrate your understanding of swaging processes and techniques, including die selection, material handling, and quality control.

- Emphasize your problem-solving skills and ability to troubleshoot and resolve issues independently.

- Showcase your teamwork and communication abilities, as well as your willingness to train and support new team members.

Essential Experience Highlights for a Strong Swaging Machine Operator Resume

- Processed large volumes of metal tubing using advanced swaging machines, exceeding production targets by 15%.

- Set up and operated swaging machines with precision, ensuring optimal performance and product quality.

- Inspected and maintained swaging machines regularly, identifying and resolving potential issues proactively.

- Optimized swaging processes by implementing innovative techniques, resulting in increased production efficiency.

- Worked closely with engineering teams to develop and implement new swaging tools and fixtures.

- Established and implemented effective quality control procedures to ensure product integrity.

Frequently Asked Questions (FAQ’s) For Swaging Machine Operator

What is a swaging machine operator?

A swaging machine operator is responsible for operating and maintaining swaging machines, which are used to shape and form metal tubing or wire.

What skills are required to be a successful swaging machine operator?

Successful swaging machine operators typically have a strong understanding of metalworking principles, as well as experience in operating and maintaining swaging machines.

What is the job outlook for swaging machine operators?

The job outlook for swaging machine operators is expected to be good, as there is a growing demand for skilled workers in the metal fabrication industry.

What are the earning prospects for swaging machine operators?

The earning prospects for swaging machine operators vary depending on their experience, skills, and location, but they can earn a competitive salary and benefits package.

What are the working conditions like for swaging machine operators?

Swaging machine operators typically work in a factory setting and may be exposed to noise, dust, and other hazards.