Are you a seasoned Sweep Molder seeking a new career path? Discover our professionally built Sweep Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

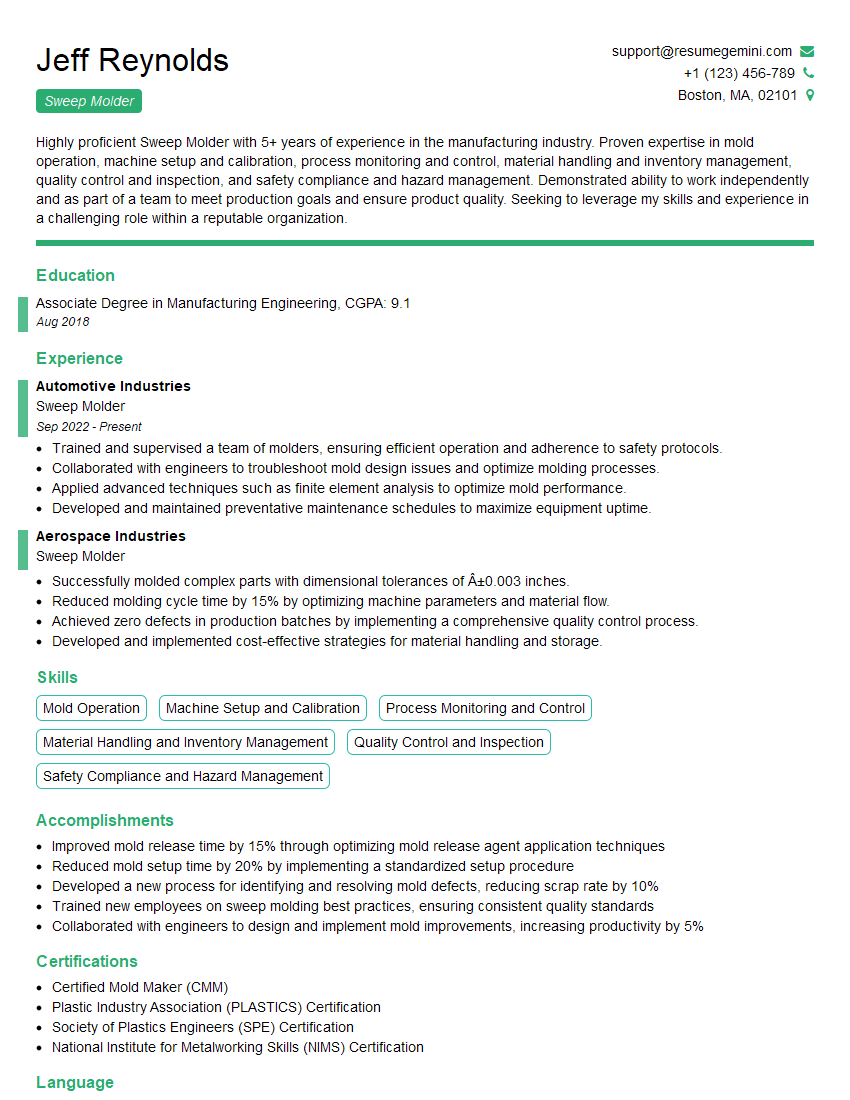

Jeff Reynolds

Sweep Molder

Summary

Highly proficient Sweep Molder with 5+ years of experience in the manufacturing industry. Proven expertise in mold operation, machine setup and calibration, process monitoring and control, material handling and inventory management, quality control and inspection, and safety compliance and hazard management. Demonstrated ability to work independently and as part of a team to meet production goals and ensure product quality. Seeking to leverage my skills and experience in a challenging role within a reputable organization.

Education

Associate Degree in Manufacturing Engineering

August 2018

Skills

- Mold Operation

- Machine Setup and Calibration

- Process Monitoring and Control

- Material Handling and Inventory Management

- Quality Control and Inspection

- Safety Compliance and Hazard Management

Work Experience

Sweep Molder

- Trained and supervised a team of molders, ensuring efficient operation and adherence to safety protocols.

- Collaborated with engineers to troubleshoot mold design issues and optimize molding processes.

- Applied advanced techniques such as finite element analysis to optimize mold performance.

- Developed and maintained preventative maintenance schedules to maximize equipment uptime.

Sweep Molder

- Successfully molded complex parts with dimensional tolerances of ±0.003 inches.

- Reduced molding cycle time by 15% by optimizing machine parameters and material flow.

- Achieved zero defects in production batches by implementing a comprehensive quality control process.

- Developed and implemented cost-effective strategies for material handling and storage.

Accomplishments

- Improved mold release time by 15% through optimizing mold release agent application techniques

- Reduced mold setup time by 20% by implementing a standardized setup procedure

- Developed a new process for identifying and resolving mold defects, reducing scrap rate by 10%

- Trained new employees on sweep molding best practices, ensuring consistent quality standards

- Collaborated with engineers to design and implement mold improvements, increasing productivity by 5%

Certificates

- Certified Mold Maker (CMM)

- Plastic Industry Association (PLASTICS) Certification

- Society of Plastics Engineers (SPE) Certification

- National Institute for Metalworking Skills (NIMS) Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sweep Molder

- Highlight your experience and skills in mold operation, machine setup and calibration, and process monitoring and control.

- Quantify your accomplishments and provide specific examples of how you have contributed to the success of your previous organizations.

- Tailor your resume to the specific requirements of the job you are applying for.

- Proofread your resume carefully before submitting it to ensure that it is error-free.

Essential Experience Highlights for a Strong Sweep Molder Resume

- Set up and calibrate sweep molding machines according to specifications.

- Operate sweep molding machines to produce plastic parts.

- Monitor and control the molding process to ensure quality and efficiency.

- Inspect finished parts to ensure they meet specifications.

- Maintain a clean and organized work area.

- Follow all safety protocols and procedures.

- Troubleshoot and resolve machine and process issues.

Frequently Asked Questions (FAQ’s) For Sweep Molder

What is the role of a Sweep Molder?

A Sweep Molder is responsible for operating and maintaining sweep molding machines to produce plastic parts. They set up and calibrate the machines, monitor and control the molding process, inspect finished parts, and maintain a clean and organized work area.

What are the key skills required for a Sweep Molder?

The key skills required for a Sweep Molder include mold operation, machine setup and calibration, process monitoring and control, material handling and inventory management, quality control and inspection, and safety compliance and hazard management.

What is the work environment of a Sweep Molder?

Sweep Molders typically work in manufacturing environments, such as factories or production plants. They may work in teams or independently, and may be required to work overtime or on weekends to meet production deadlines.

What are the career prospects for a Sweep Molder?

Sweep Molders with experience and expertise can advance to supervisory or management positions. They may also specialize in a particular area of sweep molding, such as mold design or process engineering.

What are the educational requirements for a Sweep Molder?

Most Sweep Molders have an associate degree in manufacturing engineering or a related field. Some employers may also require candidates to have experience in operating and maintaining sweep molding machines.

What are the salary expectations for a Sweep Molder?

The salary expectations for a Sweep Molder vary depending on their experience, skills, and location. According to Indeed, the average salary for a Sweep Molder in the United States is $35,000 per year.

What are the benefits of working as a Sweep Molder?

The benefits of working as a Sweep Molder include job security, opportunities for advancement, and the chance to work with cutting-edge technology.

What are the challenges of working as a Sweep Molder?

The challenges of working as a Sweep Molder include working in a fast-paced environment, meeting production deadlines, and working with potentially hazardous materials.