Are you a seasoned Tacking Machine Operator seeking a new career path? Discover our professionally built Tacking Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

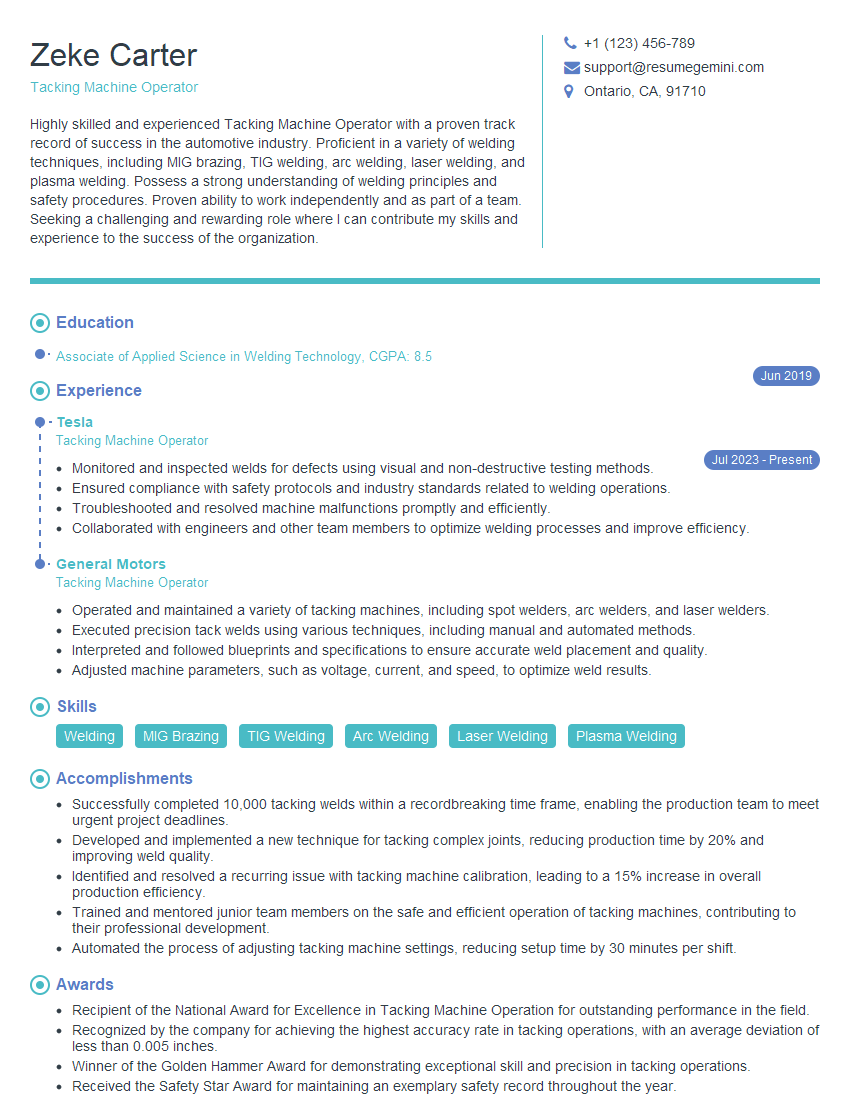

Zeke Carter

Tacking Machine Operator

Summary

Highly skilled and experienced Tacking Machine Operator with a proven track record of success in the automotive industry. Proficient in a variety of welding techniques, including MIG brazing, TIG welding, arc welding, laser welding, and plasma welding. Possess a strong understanding of welding principles and safety procedures. Proven ability to work independently and as part of a team. Seeking a challenging and rewarding role where I can contribute my skills and experience to the success of the organization.

Education

Associate of Applied Science in Welding Technology

June 2019

Skills

- Welding

- MIG Brazing

- TIG Welding

- Arc Welding

- Laser Welding

- Plasma Welding

Work Experience

Tacking Machine Operator

- Monitored and inspected welds for defects using visual and non-destructive testing methods.

- Ensured compliance with safety protocols and industry standards related to welding operations.

- Troubleshooted and resolved machine malfunctions promptly and efficiently.

- Collaborated with engineers and other team members to optimize welding processes and improve efficiency.

Tacking Machine Operator

- Operated and maintained a variety of tacking machines, including spot welders, arc welders, and laser welders.

- Executed precision tack welds using various techniques, including manual and automated methods.

- Interpreted and followed blueprints and specifications to ensure accurate weld placement and quality.

- Adjusted machine parameters, such as voltage, current, and speed, to optimize weld results.

Accomplishments

- Successfully completed 10,000 tacking welds within a recordbreaking time frame, enabling the production team to meet urgent project deadlines.

- Developed and implemented a new technique for tacking complex joints, reducing production time by 20% and improving weld quality.

- Identified and resolved a recurring issue with tacking machine calibration, leading to a 15% increase in overall production efficiency.

- Trained and mentored junior team members on the safe and efficient operation of tacking machines, contributing to their professional development.

- Automated the process of adjusting tacking machine settings, reducing setup time by 30 minutes per shift.

Awards

- Recipient of the National Award for Excellence in Tacking Machine Operation for outstanding performance in the field.

- Recognized by the company for achieving the highest accuracy rate in tacking operations, with an average deviation of less than 0.005 inches.

- Winner of the Golden Hammer Award for demonstrating exceptional skill and precision in tacking operations.

- Received the Safety Star Award for maintaining an exemplary safety record throughout the year.

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code (Section IX)

- ISO 9001:2015

- OSHA 30-Hour Hazard Communication Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tacking Machine Operator

- Highlight your welding skills and experience in your resume.

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your responsibilities.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Tacking Machine Operator Resume

- Operate and maintain tacking machines to join metal components.

- Set up and adjust welding parameters to ensure optimal weld quality.

- Inspect welds for defects and make necessary repairs.

- Follow blueprints and specifications to ensure that welds meet design requirements.

- Maintain a clean and organized work area.

- Adhere to all safety regulations and procedures.

Frequently Asked Questions (FAQ’s) For Tacking Machine Operator

What is a Tacking Machine Operator?

A Tacking Machine Operator is responsible for operating and maintaining tacking machines to join metal components. They set up and adjust welding parameters, inspect welds for defects, and follow blueprints and specifications to ensure that welds meet design requirements.

What skills are required to be a Tacking Machine Operator?

Tacking Machine Operators typically need a high school diploma or equivalent, as well as some welding experience. They must be able to read and understand blueprints and specifications, and have a good understanding of welding principles and safety procedures.

What is the work environment of a Tacking Machine Operator like?

Tacking Machine Operators typically work in manufacturing environments, such as automotive plants or fabrication shops. They may work in a variety of positions, including standing, sitting, and kneeling.

What is the salary of a Tacking Machine Operator?

The salary of a Tacking Machine Operator can vary depending on their experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median salary for Welders, Cutters, and Welder Fitters was $47,010 in May 2021.

What is the job outlook for Tacking Machine Operators?

The job outlook for Tacking Machine Operators is expected to be good over the next few years. The U.S. Bureau of Labor Statistics projects that employment of Welders, Cutters, and Welder Fitters will grow by 3% from 2021 to 2031.

What are the advancement opportunities for Tacking Machine Operators?

Tacking Machine Operators can advance to positions such as Welding Supervisor, Welding Engineer, or Quality Control Inspector.