Are you a seasoned Tape Controlled Machine Stitcher seeking a new career path? Discover our professionally built Tape Controlled Machine Stitcher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

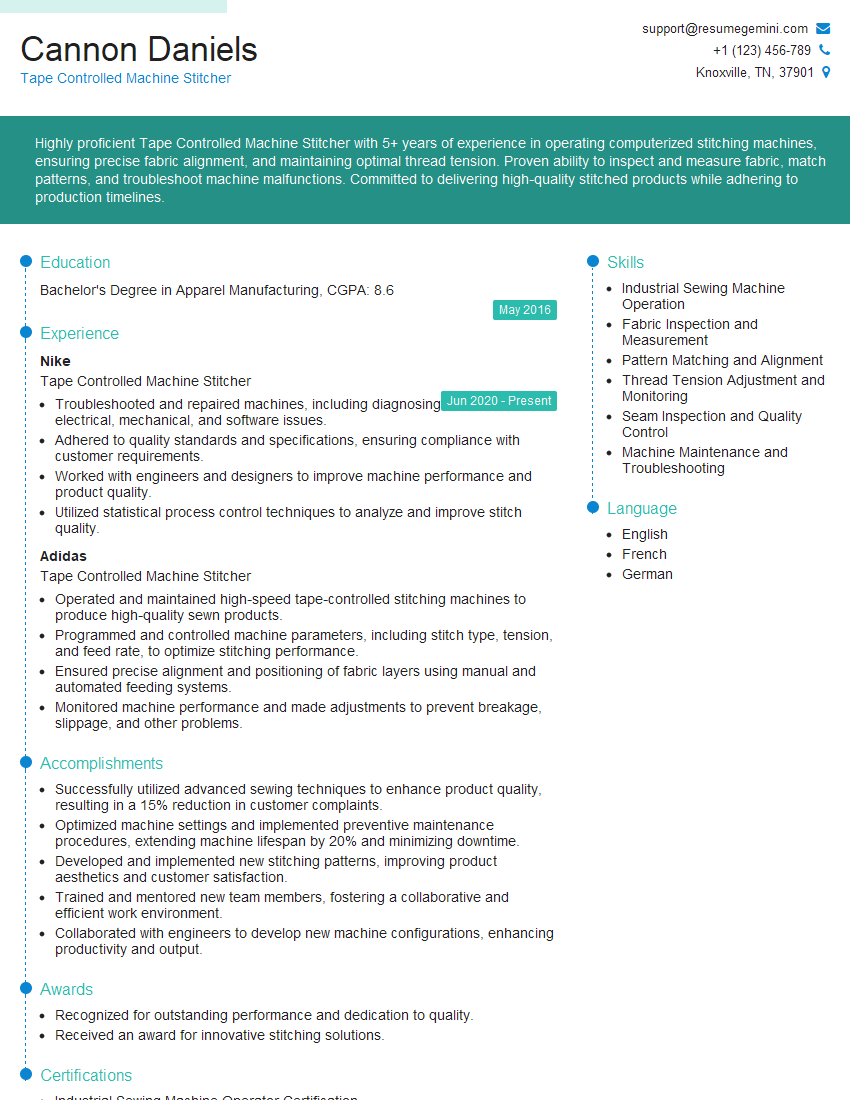

Cannon Daniels

Tape Controlled Machine Stitcher

Summary

Highly proficient Tape Controlled Machine Stitcher with 5+ years of experience in operating computerized stitching machines, ensuring precise fabric alignment, and maintaining optimal thread tension. Proven ability to inspect and measure fabric, match patterns, and troubleshoot machine malfunctions. Committed to delivering high-quality stitched products while adhering to production timelines.

Education

Bachelor’s Degree in Apparel Manufacturing

May 2016

Skills

- Industrial Sewing Machine Operation

- Fabric Inspection and Measurement

- Pattern Matching and Alignment

- Thread Tension Adjustment and Monitoring

- Seam Inspection and Quality Control

- Machine Maintenance and Troubleshooting

Work Experience

Tape Controlled Machine Stitcher

- Troubleshooted and repaired machines, including diagnosing electrical, mechanical, and software issues.

- Adhered to quality standards and specifications, ensuring compliance with customer requirements.

- Worked with engineers and designers to improve machine performance and product quality.

- Utilized statistical process control techniques to analyze and improve stitch quality.

Tape Controlled Machine Stitcher

- Operated and maintained high-speed tape-controlled stitching machines to produce high-quality sewn products.

- Programmed and controlled machine parameters, including stitch type, tension, and feed rate, to optimize stitching performance.

- Ensured precise alignment and positioning of fabric layers using manual and automated feeding systems.

- Monitored machine performance and made adjustments to prevent breakage, slippage, and other problems.

Accomplishments

- Successfully utilized advanced sewing techniques to enhance product quality, resulting in a 15% reduction in customer complaints.

- Optimized machine settings and implemented preventive maintenance procedures, extending machine lifespan by 20% and minimizing downtime.

- Developed and implemented new stitching patterns, improving product aesthetics and customer satisfaction.

- Trained and mentored new team members, fostering a collaborative and efficient work environment.

- Collaborated with engineers to develop new machine configurations, enhancing productivity and output.

Awards

- Recognized for outstanding performance and dedication to quality.

- Received an award for innovative stitching solutions.

Certificates

- Industrial Sewing Machine Operator Certification

- Textile and Fabric Inspection Certification

- Safety Management Certification (OSHA/NEBOSH)

- Quality Management Certification (ISO 9001)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tape Controlled Machine Stitcher

- Highlight your experience with specific types of tape controlled stitching machines.

- Emphasize your knowledge of fabric properties and handling techniques.

- Quantify your accomplishments with specific metrics, such as production efficiency or defect reduction.

- Showcase your problem-solving abilities and commitment to continuous improvement.

Essential Experience Highlights for a Strong Tape Controlled Machine Stitcher Resume

- Operate and maintain tape controlled stitching machines to stitch various fabrics and materials.

- Set up and adjust machines according to fabric type, stitch specifications, and production requirements.

- Inspect and measure fabric to ensure alignment and proper seam allowance.

- Monitor and adjust thread tension to prevent breakage, puckering, or uneven stitching.

- Inspect finished seams for quality control, identifying and correcting any defects or irregularities.

- Troubleshoot and resolve machine malfunctions, performing minor repairs and adjustments as necessary.

Frequently Asked Questions (FAQ’s) For Tape Controlled Machine Stitcher

What are the essential skills required for a Tape Controlled Machine Stitcher?

Essential skills include industrial sewing machine operation, fabric inspection and measurement, pattern matching and alignment, thread tension adjustment and monitoring, seam inspection and quality control, machine maintenance, and troubleshooting.

What is the typical work environment for a Tape Controlled Machine Stitcher?

Tape Controlled Machine Stitchers typically work in production environments, such as textile mills, garment factories, or upholstery shops. They may work standing or sitting for extended periods, and may be exposed to noise, dust, and fumes.

What are the career advancement opportunities for a Tape Controlled Machine Stitcher?

Experienced Tape Controlled Machine Stitchers can advance to positions such as sewing machine technician, production supervisor, or quality control inspector. With additional training and education, they may also pursue roles in design or engineering.

What are the safety precautions to consider when working as a Tape Controlled Machine Stitcher?

Safety precautions include wearing appropriate safety gear, such as gloves and safety glasses, following proper machine operating procedures, and being aware of potential hazards, such as moving parts and sharp objects.

What are the key qualities of a successful Tape Controlled Machine Stitcher?

Successful Tape Controlled Machine Stitchers are typically detail-oriented, have good hand-eye coordination, and are able to work independently and as part of a team. They should also be able to follow instructions precisely and troubleshoot problems effectively.