Are you a seasoned Tape Maker seeking a new career path? Discover our professionally built Tape Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

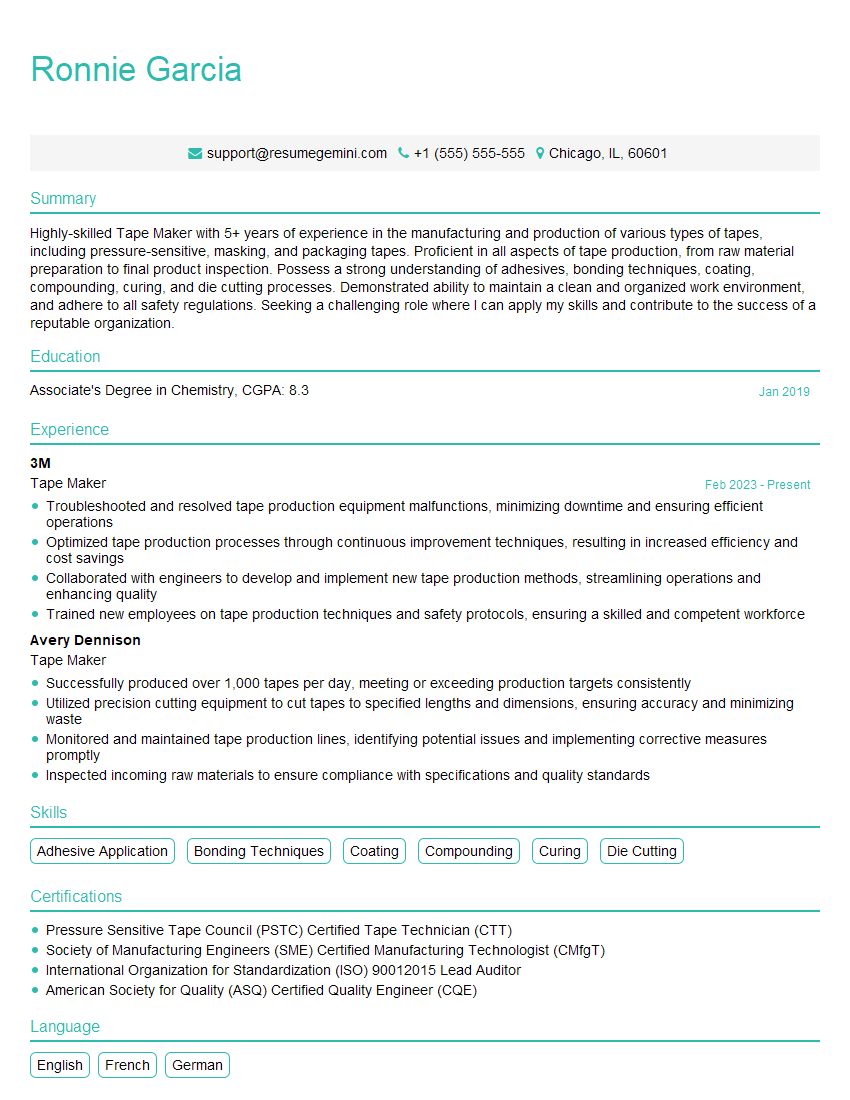

Ronnie Garcia

Tape Maker

Summary

Highly-skilled Tape Maker with 5+ years of experience in the manufacturing and production of various types of tapes, including pressure-sensitive, masking, and packaging tapes. Proficient in all aspects of tape production, from raw material preparation to final product inspection. Possess a strong understanding of adhesives, bonding techniques, coating, compounding, curing, and die cutting processes. Demonstrated ability to maintain a clean and organized work environment, and adhere to all safety regulations. Seeking a challenging role where I can apply my skills and contribute to the success of a reputable organization.

Education

Associate’s Degree in Chemistry

January 2019

Skills

- Adhesive Application

- Bonding Techniques

- Coating

- Compounding

- Curing

- Die Cutting

Work Experience

Tape Maker

- Troubleshooted and resolved tape production equipment malfunctions, minimizing downtime and ensuring efficient operations

- Optimized tape production processes through continuous improvement techniques, resulting in increased efficiency and cost savings

- Collaborated with engineers to develop and implement new tape production methods, streamlining operations and enhancing quality

- Trained new employees on tape production techniques and safety protocols, ensuring a skilled and competent workforce

Tape Maker

- Successfully produced over 1,000 tapes per day, meeting or exceeding production targets consistently

- Utilized precision cutting equipment to cut tapes to specified lengths and dimensions, ensuring accuracy and minimizing waste

- Monitored and maintained tape production lines, identifying potential issues and implementing corrective measures promptly

- Inspected incoming raw materials to ensure compliance with specifications and quality standards

Certificates

- Pressure Sensitive Tape Council (PSTC) Certified Tape Technician (CTT)

- Society of Manufacturing Engineers (SME) Certified Manufacturing Technologist (CMfgT)

- International Organization for Standardization (ISO) 90012015 Lead Auditor

- American Society for Quality (ASQ) Certified Quality Engineer (CQE)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tape Maker

Highlight your technical skills:

Emphasize your proficiency in adhesive application, bonding techniques, coating, compounding, curing, and die cutting.Quantify your accomplishments:

Use specific numbers and metrics to demonstrate the impact of your work.Demonstrate your knowledge of industry standards:

Mention your familiarity with relevant industry standards, such as ASTM and ISO.Tailor your resume to the job description:

Highlight the skills and experience that are most relevant to the specific role you are applying for.Proofread carefully:

Ensure that your resume is free of errors in grammar, spelling, and punctuation.

Essential Experience Highlights for a Strong Tape Maker Resume

- Operate and maintain tape production equipment, including extruders, coaters, and rewinders.

- Prepare and mix adhesive formulations according to specifications.

- Control the thickness, width, and tension of tape during production.

- Inspect finished tapes for defects and ensure they meet quality standards.

- Troubleshoot and resolve production issues to maintain efficiency.

- Maintain a clean and organized work area, and adhere to all safety regulations.

- Collaborate with other departments to ensure smooth production processes.

Frequently Asked Questions (FAQ’s) For Tape Maker

What is the primary role of a Tape Maker?

A Tape Maker is responsible for operating and maintaining tape production equipment, preparing and mixing adhesive formulations, controlling the thickness, width, and tension of tape during production, inspecting finished tapes for defects, and troubleshooting and resolving production issues.

What are the essential skills required for a Tape Maker?

Essential skills for a Tape Maker include adhesive application, bonding techniques, coating, compounding, curing, and die cutting. Additionally, they should have a strong understanding of quality control processes and safety regulations.

What are the career prospects for a Tape Maker?

Tape Makers can advance to supervisory or management roles within the manufacturing industry. They may also pursue further education or training to specialize in a particular area, such as adhesive chemistry or product development.

What is the average salary for a Tape Maker?

The average salary for a Tape Maker varies depending on experience, location, and industry. According to Salary.com, the average salary for a Tape Maker in the United States is around $50,000 per year.

What are the working conditions like for a Tape Maker?

Tape Makers typically work in manufacturing facilities. They may be exposed to noise, dust, and chemicals. They must also be able to work in a fast-paced environment and meet production deadlines.

What is the job outlook for Tape Makers?

The job outlook for Tape Makers is expected to be stable in the coming years. The demand for tape products is expected to remain steady, and there will be a need for skilled workers to operate and maintain tape production equipment.