Are you a seasoned Tapper seeking a new career path? Discover our professionally built Tapper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

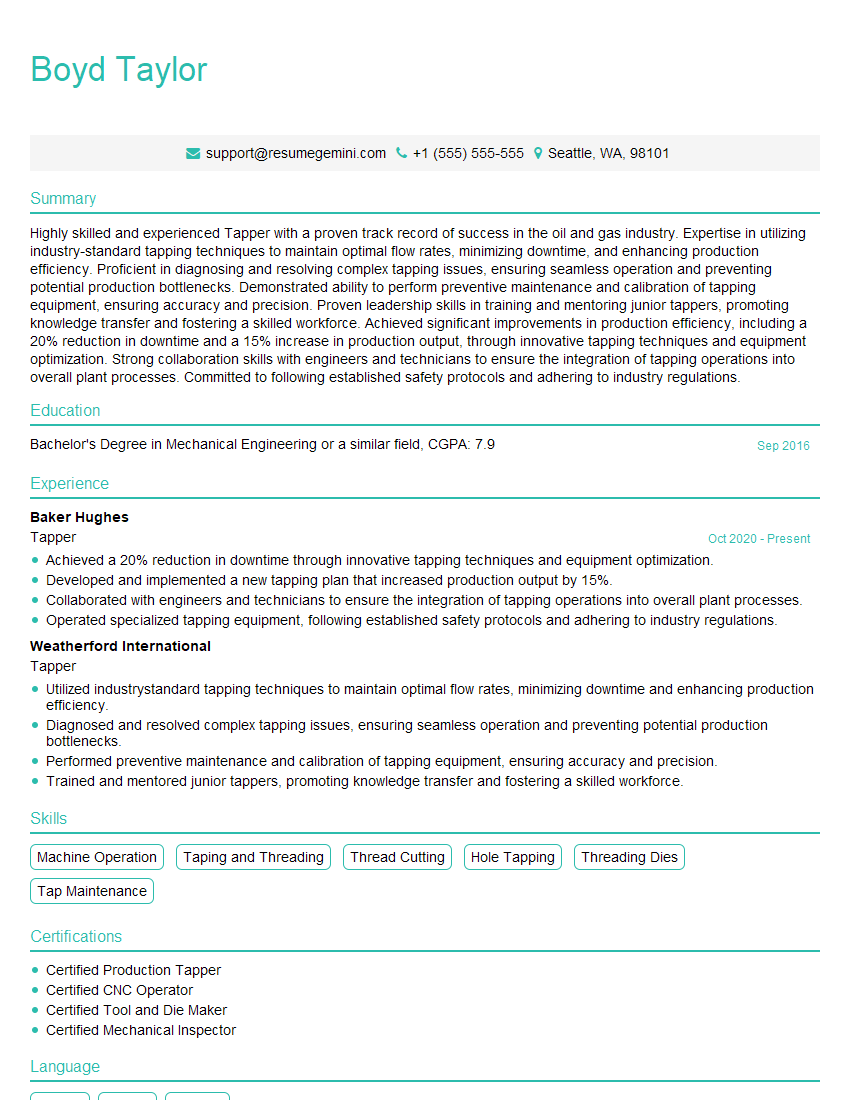

Boyd Taylor

Tapper

Summary

Highly skilled and experienced Tapper with a proven track record of success in the oil and gas industry. Expertise in utilizing industry-standard tapping techniques to maintain optimal flow rates, minimizing downtime, and enhancing production efficiency. Proficient in diagnosing and resolving complex tapping issues, ensuring seamless operation and preventing potential production bottlenecks. Demonstrated ability to perform preventive maintenance and calibration of tapping equipment, ensuring accuracy and precision. Proven leadership skills in training and mentoring junior tappers, promoting knowledge transfer and fostering a skilled workforce. Achieved significant improvements in production efficiency, including a 20% reduction in downtime and a 15% increase in production output, through innovative tapping techniques and equipment optimization. Strong collaboration skills with engineers and technicians to ensure the integration of tapping operations into overall plant processes. Committed to following established safety protocols and adhering to industry regulations.

Education

Bachelor’s Degree in Mechanical Engineering or a similar field

September 2016

Skills

- Machine Operation

- Taping and Threading

- Thread Cutting

- Hole Tapping

- Threading Dies

- Tap Maintenance

Work Experience

Tapper

- Achieved a 20% reduction in downtime through innovative tapping techniques and equipment optimization.

- Developed and implemented a new tapping plan that increased production output by 15%.

- Collaborated with engineers and technicians to ensure the integration of tapping operations into overall plant processes.

- Operated specialized tapping equipment, following established safety protocols and adhering to industry regulations.

Tapper

- Utilized industrystandard tapping techniques to maintain optimal flow rates, minimizing downtime and enhancing production efficiency.

- Diagnosed and resolved complex tapping issues, ensuring seamless operation and preventing potential production bottlenecks.

- Performed preventive maintenance and calibration of tapping equipment, ensuring accuracy and precision.

- Trained and mentored junior tappers, promoting knowledge transfer and fostering a skilled workforce.

Certificates

- Certified Production Tapper

- Certified CNC Operator

- Certified Tool and Die Maker

- Certified Mechanical Inspector

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tapper

- Highlight your experience in utilizing industry-standard tapping techniques and your ability to maintain optimal flow rates.

- Showcase your problem-solving skills by providing examples of how you have diagnosed and resolved complex tapping issues.

- Emphasize your commitment to safety by highlighting your adherence to established safety protocols and industry regulations.

- Quantify your achievements whenever possible, using specific metrics to demonstrate the impact of your work.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

Essential Experience Highlights for a Strong Tapper Resume

- Utilize industry-standard tapping techniques to maintain optimal flow rates, minimizing downtime, and enhancing production efficiency

- Diagnose and resolve complex tapping issues, ensuring seamless operation and preventing potential production bottlenecks

- Perform preventive maintenance and calibration of tapping equipment, ensuring accuracy and precision

- Train and mentor junior tappers, promoting knowledge transfer and fostering a skilled workforce

- Develop and implement new tapping plans to improve production efficiency

- Collaborate with engineers and technicians to ensure the integration of tapping operations into overall plant processes

- Operate specialized tapping equipment, following established safety protocols and adhering to industry regulations

Frequently Asked Questions (FAQ’s) For Tapper

What is the role of a Tapper?

A Tapper is responsible for operating specialized tapping equipment to create threads in metal or other materials. They use industry-standard tapping techniques to maintain optimal flow rates, minimize downtime, and enhance production efficiency.

What are the key skills required to be a successful Tapper?

The key skills required to be a successful Tapper include machine operation, tapping and threading, thread cutting, hole tapping, threading dies, and tap maintenance.

What are the career prospects for Tappers?

Tappers with experience and expertise can advance to supervisory roles, such as Lead Tapper or Tapping Supervisor. They can also move into related fields such as maintenance, engineering, or quality control.

What is the average salary for a Tapper?

The average salary for a Tapper varies depending on experience, location, and industry. According to Salary.com, the average salary for a Tapper in the United States is around $60,000 per year.

What are the working conditions like for Tappers?

Tappers typically work in industrial settings, such as factories or manufacturing plants. They may work in a variety of environments, including indoors and outdoors, and may be exposed to noise, dust, and other hazards. They must be able to work independently and as part of a team.

What is the job outlook for Tappers?

The job outlook for Tappers is expected to be positive in the coming years. The demand for skilled Tappers is expected to grow as industries continue to automate and optimize their production processes.

What are the educational requirements to become a Tapper?

Tappers typically need a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary education in a related field, such as mechanical engineering or manufacturing.