Are you a seasoned Tarring Machine Operator seeking a new career path? Discover our professionally built Tarring Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

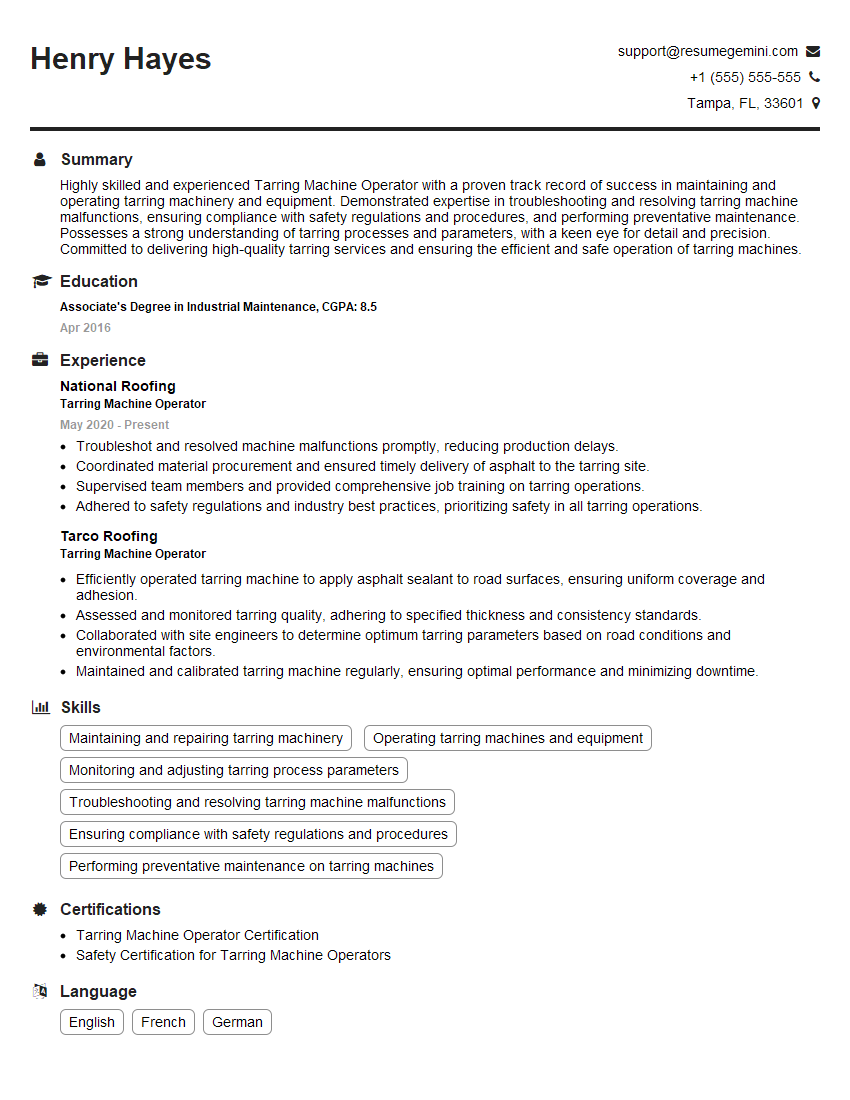

Henry Hayes

Tarring Machine Operator

Summary

Highly skilled and experienced Tarring Machine Operator with a proven track record of success in maintaining and operating tarring machinery and equipment. Demonstrated expertise in troubleshooting and resolving tarring machine malfunctions, ensuring compliance with safety regulations and procedures, and performing preventative maintenance. Possesses a strong understanding of tarring processes and parameters, with a keen eye for detail and precision. Committed to delivering high-quality tarring services and ensuring the efficient and safe operation of tarring machines.

Education

Associate’s Degree in Industrial Maintenance

April 2016

Skills

- Maintaining and repairing tarring machinery

- Operating tarring machines and equipment

- Monitoring and adjusting tarring process parameters

- Troubleshooting and resolving tarring machine malfunctions

- Ensuring compliance with safety regulations and procedures

- Performing preventative maintenance on tarring machines

Work Experience

Tarring Machine Operator

- Troubleshot and resolved machine malfunctions promptly, reducing production delays.

- Coordinated material procurement and ensured timely delivery of asphalt to the tarring site.

- Supervised team members and provided comprehensive job training on tarring operations.

- Adhered to safety regulations and industry best practices, prioritizing safety in all tarring operations.

Tarring Machine Operator

- Efficiently operated tarring machine to apply asphalt sealant to road surfaces, ensuring uniform coverage and adhesion.

- Assessed and monitored tarring quality, adhering to specified thickness and consistency standards.

- Collaborated with site engineers to determine optimum tarring parameters based on road conditions and environmental factors.

- Maintained and calibrated tarring machine regularly, ensuring optimal performance and minimizing downtime.

Certificates

- Tarring Machine Operator Certification

- Safety Certification for Tarring Machine Operators

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tarring Machine Operator

- Highlight your experience and expertise in maintaining and operating tarring machinery.

- Quantify your accomplishments with specific metrics to demonstrate your impact on productivity and efficiency.

- Showcase your knowledge of tarring processes and parameters, and your ability to troubleshoot and resolve complex issues.

- Demonstrate your commitment to safety and compliance by highlighting your adherence to established protocols and procedures.

- Include keywords related to tarring machinery, operation, maintenance, troubleshooting, and safety to optimize your resume for search engines.

Essential Experience Highlights for a Strong Tarring Machine Operator Resume

- Maintain and repair tarring machinery and equipment to ensure optimal performance and efficiency.

- Operate tarring machines and equipment in accordance with established operating procedures and safety protocols.

- Monitor and adjust tarring process parameters to achieve desired coating thickness, consistency, and adhesion.

- Troubleshoot and resolve tarring machine malfunctions promptly and effectively to minimize downtime and maintain production schedules.

- Ensure compliance with safety regulations and procedures to protect personnel, equipment, and the environment.

- Perform preventative maintenance on tarring machines, including regular inspections, lubrication, and cleaning, to extend their lifespan and minimize breakdowns.

Frequently Asked Questions (FAQ’s) For Tarring Machine Operator

What are the key skills required to be a successful Tarring Machine Operator?

The key skills required to be a successful Tarring Machine Operator include: mechanical aptitude, attention to detail, problem-solving abilities, knowledge of tarring processes, and a strong commitment to safety.

What are the primary responsibilities of a Tarring Machine Operator?

The primary responsibilities of a Tarring Machine Operator include: operating and maintaining tarring machinery, monitoring and adjusting process parameters, troubleshooting and resolving malfunctions, performing preventative maintenance, and ensuring compliance with safety regulations.

What industries commonly utilize Tarring Machine Operators?

Tarring Machine Operators are commonly employed in industries such as roofing, construction, and manufacturing.

What is the average salary for a Tarring Machine Operator?

The average salary for a Tarring Machine Operator varies depending on experience, location, and industry, but typically ranges from $30,000 to $50,000 per year.

What are the career advancement opportunities for Tarring Machine Operators?

Tarring Machine Operators can advance their careers by gaining additional experience and certifications, and by taking on supervisory roles or positions in related fields such as equipment maintenance or process engineering.

What are the potential hazards associated with being a Tarring Machine Operator?

Potential hazards associated with being a Tarring Machine Operator include: exposure to hot tar, fumes, and machinery, as well as the risk of burns, injuries, and falls.

What safety precautions should Tarring Machine Operators take?

Tarring Machine Operators should wear appropriate personal protective equipment (PPE), follow established safety procedures, and be aware of potential hazards to minimize the risk of accidents and injuries.

How can I become a Tarring Machine Operator?

To become a Tarring Machine Operator, you typically need to complete a high school diploma or equivalent, and then gain experience through on-the-job training or an apprenticeship program.