Are you a seasoned Textile Conversion Manager seeking a new career path? Discover our professionally built Textile Conversion Manager Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

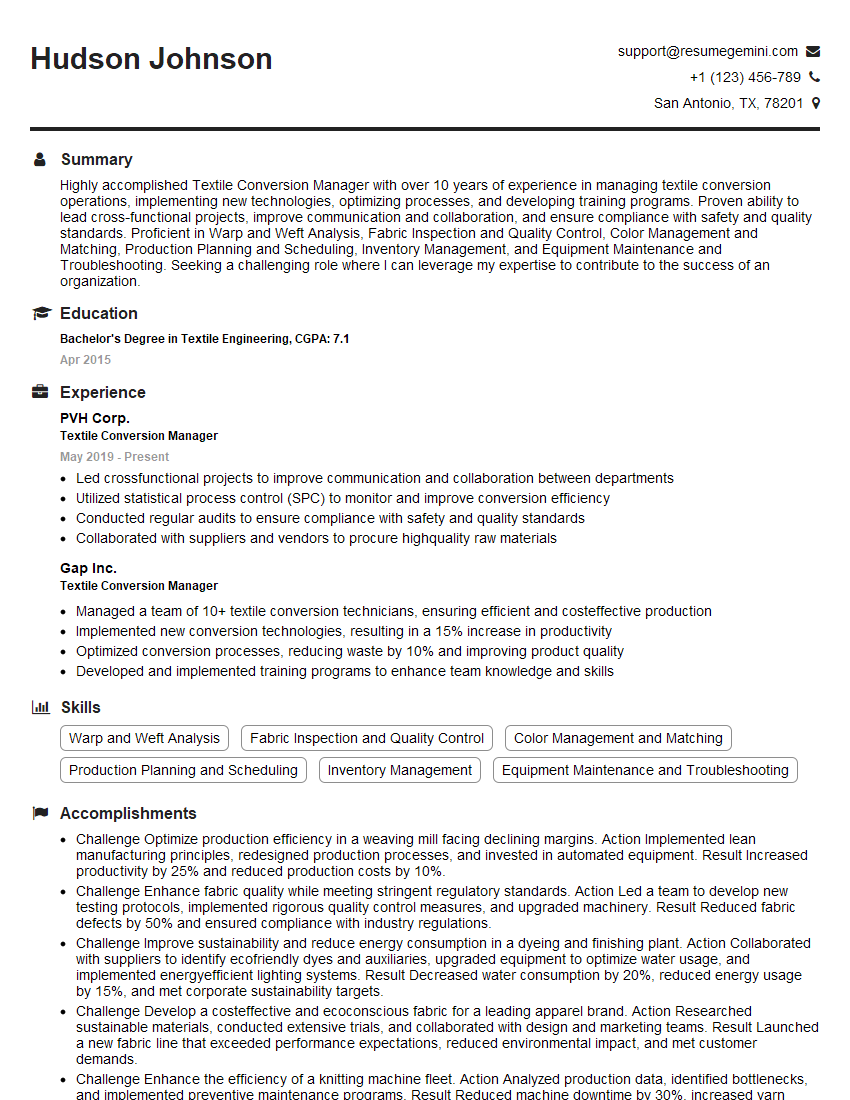

Hudson Johnson

Textile Conversion Manager

Summary

Highly accomplished Textile Conversion Manager with over 10 years of experience in managing textile conversion operations, implementing new technologies, optimizing processes, and developing training programs. Proven ability to lead cross-functional projects, improve communication and collaboration, and ensure compliance with safety and quality standards. Proficient in Warp and Weft Analysis, Fabric Inspection and Quality Control, Color Management and Matching, Production Planning and Scheduling, Inventory Management, and Equipment Maintenance and Troubleshooting. Seeking a challenging role where I can leverage my expertise to contribute to the success of an organization.

Education

Bachelor’s Degree in Textile Engineering

April 2015

Skills

- Warp and Weft Analysis

- Fabric Inspection and Quality Control

- Color Management and Matching

- Production Planning and Scheduling

- Inventory Management

- Equipment Maintenance and Troubleshooting

Work Experience

Textile Conversion Manager

- Led crossfunctional projects to improve communication and collaboration between departments

- Utilized statistical process control (SPC) to monitor and improve conversion efficiency

- Conducted regular audits to ensure compliance with safety and quality standards

- Collaborated with suppliers and vendors to procure highquality raw materials

Textile Conversion Manager

- Managed a team of 10+ textile conversion technicians, ensuring efficient and costeffective production

- Implemented new conversion technologies, resulting in a 15% increase in productivity

- Optimized conversion processes, reducing waste by 10% and improving product quality

- Developed and implemented training programs to enhance team knowledge and skills

Accomplishments

- Challenge Optimize production efficiency in a weaving mill facing declining margins. Action Implemented lean manufacturing principles, redesigned production processes, and invested in automated equipment. Result Increased productivity by 25% and reduced production costs by 10%.

- Challenge Enhance fabric quality while meeting stringent regulatory standards. Action Led a team to develop new testing protocols, implemented rigorous quality control measures, and upgraded machinery. Result Reduced fabric defects by 50% and ensured compliance with industry regulations.

- Challenge Improve sustainability and reduce energy consumption in a dyeing and finishing plant. Action Collaborated with suppliers to identify ecofriendly dyes and auxiliaries, upgraded equipment to optimize water usage, and implemented energyefficient lighting systems. Result Decreased water consumption by 20%, reduced energy usage by 15%, and met corporate sustainability targets.

- Challenge Develop a costeffective and ecoconscious fabric for a leading apparel brand. Action Researched sustainable materials, conducted extensive trials, and collaborated with design and marketing teams. Result Launched a new fabric line that exceeded performance expectations, reduced environmental impact, and met customer demands.

- Challenge Enhance the efficiency of a knitting machine fleet. Action Analyzed production data, identified bottlenecks, and implemented preventive maintenance programs. Result Reduced machine downtime by 30%, increased yarn utilization by 5%, and improved overall production efficiency.

Awards

- Received the Textile Innovator of the Year award for developing a novel yarn spinning technology that significantly improved fabric strength and durability.

- Recognized with the Sustainable Textile Production Award for pioneering innovative practices that minimized waste and reduced environmental impact.

- Honored with the Textile Conversion Excellence Award for successfully implementing a stateoftheart fiber conversion facility that significantly improved product quality and customer satisfaction.

- Recipient of the Textile Technology Advancement Award for developing a breakthrough yarn sizing technology that enhanced fabric handle and performance.

Certificates

- Certified Textile Converter (CTC)

- Certified Colorist (CC)

- Six Sigma Green Belt

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Textile Conversion Manager

- Quantify your accomplishments and provide specific metrics to demonstrate your impact.

- Highlight your technical expertise and proficiency in textile conversion technologies and processes.

- Showcase your leadership skills and ability to manage and develop a team.

- Emphasize your commitment to quality and continuous improvement.

- Use keywords relevant to the textile conversion industry throughout your resume.

Essential Experience Highlights for a Strong Textile Conversion Manager Resume

- Managed a team of 10+ textile conversion technicians, ensuring efficient and cost-effective production.

- Implemented new conversion technologies, resulting in a 15% increase in productivity.

- Optimized conversion processes, reducing waste by 10% and improving product quality.

- Developed and implemented training programs to enhance team knowledge and skills.

- Led cross-functional projects to improve communication and collaboration between departments.

- Utilized statistical process control (SPC) to monitor and improve conversion efficiency.

- Conducted regular audits to ensure compliance with safety and quality standards.

Frequently Asked Questions (FAQ’s) For Textile Conversion Manager

What are the key responsibilities of a Textile Conversion Manager?

Textile Conversion Managers are responsible for overseeing the conversion of textile materials into finished products. They manage teams of technicians, implement new technologies, optimize processes, and ensure compliance with safety and quality standards.

What are the qualifications for a Textile Conversion Manager?

Textile Conversion Managers typically have a Bachelor’s Degree in Textile Engineering or a related field, along with several years of experience in the textile industry.

What are the career prospects for a Textile Conversion Manager?

Textile Conversion Managers can advance to leadership roles within the textile industry, such as Production Manager or Plant Manager. They may also pursue careers in research and development or technical sales.

What are the challenges faced by Textile Conversion Managers?

Textile Conversion Managers face challenges such as managing production costs, ensuring product quality, and keeping up with new technologies. They must also be able to work effectively with a team of technicians.

What are the key skills required for a Textile Conversion Manager?

Textile Conversion Managers need strong technical skills in textile conversion processes, as well as leadership and management skills. They must also be able to work independently and as part of a team.

What is the salary range for a Textile Conversion Manager?

The salary range for a Textile Conversion Manager varies depending on experience and location. According to Salary.com, the average salary for a Textile Conversion Manager in the United States is $75,000.