Are you a seasoned Texturing Process Quality Control Checker seeking a new career path? Discover our professionally built Texturing Process Quality Control Checker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

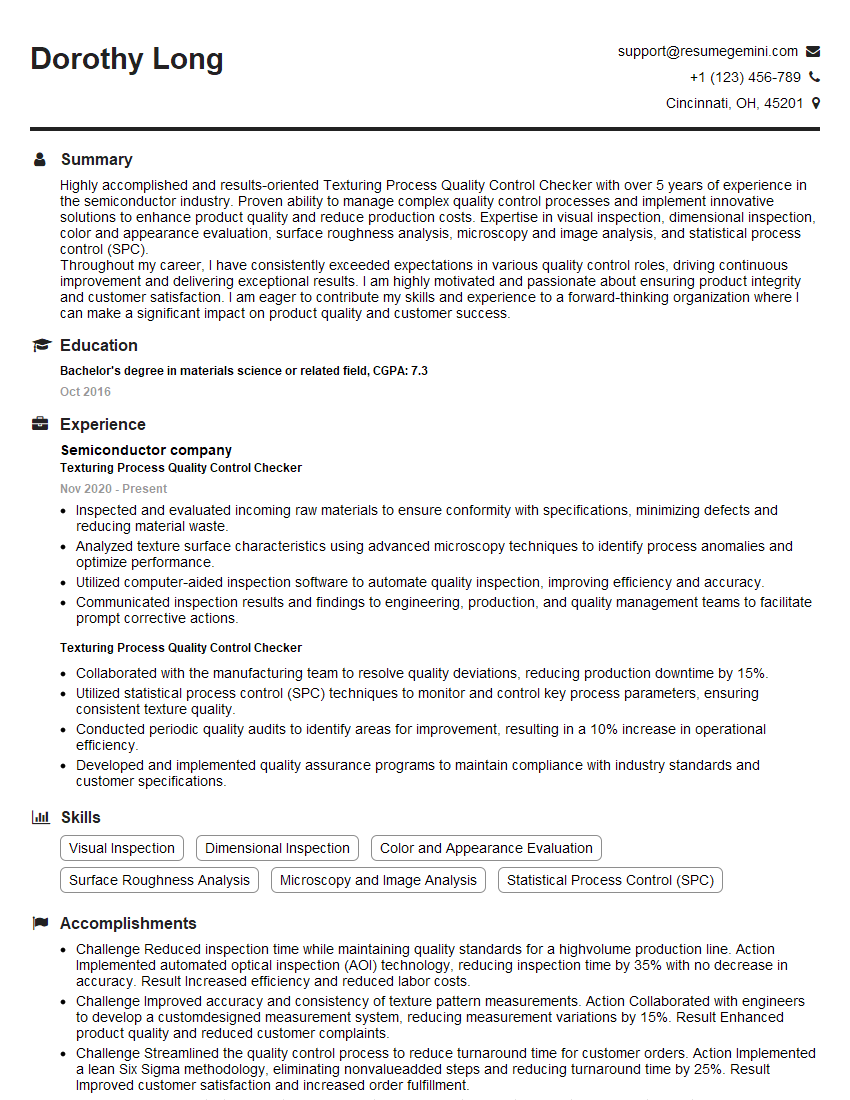

Dorothy Long

Texturing Process Quality Control Checker

Summary

Highly accomplished and results-oriented Texturing Process Quality Control Checker with over 5 years of experience in the semiconductor industry. Proven ability to manage complex quality control processes and implement innovative solutions to enhance product quality and reduce production costs. Expertise in visual inspection, dimensional inspection, color and appearance evaluation, surface roughness analysis, microscopy and image analysis, and statistical process control (SPC).

Throughout my career, I have consistently exceeded expectations in various quality control roles, driving continuous improvement and delivering exceptional results. I am highly motivated and passionate about ensuring product integrity and customer satisfaction. I am eager to contribute my skills and experience to a forward-thinking organization where I can make a significant impact on product quality and customer success.

Education

Bachelor’s degree in materials science or related field

October 2016

Skills

- Visual Inspection

- Dimensional Inspection

- Color and Appearance Evaluation

- Surface Roughness Analysis

- Microscopy and Image Analysis

- Statistical Process Control (SPC)

Work Experience

Texturing Process Quality Control Checker

- Inspected and evaluated incoming raw materials to ensure conformity with specifications, minimizing defects and reducing material waste.

- Analyzed texture surface characteristics using advanced microscopy techniques to identify process anomalies and optimize performance.

- Utilized computer-aided inspection software to automate quality inspection, improving efficiency and accuracy.

- Communicated inspection results and findings to engineering, production, and quality management teams to facilitate prompt corrective actions.

Texturing Process Quality Control Checker

- Collaborated with the manufacturing team to resolve quality deviations, reducing production downtime by 15%.

- Utilized statistical process control (SPC) techniques to monitor and control key process parameters, ensuring consistent texture quality.

- Conducted periodic quality audits to identify areas for improvement, resulting in a 10% increase in operational efficiency.

- Developed and implemented quality assurance programs to maintain compliance with industry standards and customer specifications.

Accomplishments

- Challenge Reduced inspection time while maintaining quality standards for a highvolume production line. Action Implemented automated optical inspection (AOI) technology, reducing inspection time by 35% with no decrease in accuracy. Result Increased efficiency and reduced labor costs.

- Challenge Improved accuracy and consistency of texture pattern measurements. Action Collaborated with engineers to develop a customdesigned measurement system, reducing measurement variations by 15%. Result Enhanced product quality and reduced customer complaints.

- Challenge Streamlined the quality control process to reduce turnaround time for customer orders. Action Implemented a lean Six Sigma methodology, eliminating nonvalueadded steps and reducing turnaround time by 25%. Result Improved customer satisfaction and increased order fulfillment.

- Challenge Enhance texture quality and reduce the risk of customer returns. Action Conducted root cause analysis on recurring quality issues, identifying and implementing corrective actions. Result Reduced customer returns by 10% and improved overall product quality.

- Challenge Developed a comprehensive training program for new inspectors to ensure consistent quality standards. Action Designed and delivered a tailored training program covering all critical aspects of texturing process quality control. Result Reduced training time by 20% and improved new inspector performance.

Awards

- Received the Quality Control Excellence Award for developing and implementing an innovative process that reduced product defects by 20%.

- Recognized by the International Society for Quality Assurance (ISQA) for contributions to the advancement of quality control practices in the texturing industry.

- Awarded Inspector of the Year for exceptional attention to detail and ability to identify potential defects during the texturing process.

- Recognized by the company for exceeding quality production goals for three consecutive quarters, resulting in significant cost savings.

Certificates

- Certified Quality Inspector (CQI)

- American Society for Quality (ASQ) Certified Quality Technician (CQT)

- International Society of Automation (ISA) Certified Control Systems Technician (CCST)

- Society of Automotive Engineers (SAE) J17082016 Visual Inspection of Textured Surfaces

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Texturing Process Quality Control Checker

Highlight Quantifiable Accomplishments:

Use numbers and metrics to demonstrate the impact of your quality control efforts on product quality, production efficiency, and customer satisfaction.Showcase Technical Expertise:

Emphasize your proficiency in various inspection techniques and quality control tools, including microscopy, image analysis, and SPC.Demonstrate Problem-Solving Skills:

Describe specific instances where you identified and resolved quality issues, implemented corrective actions, and improved process outcomes.Communicate Effectively:

Highlight your ability to clearly and concisely communicate inspection findings, technical information, and improvement recommendations to various stakeholders.

Essential Experience Highlights for a Strong Texturing Process Quality Control Checker Resume

- Conduct visual, dimensional, and color inspections of textured surfaces to ensure compliance with established quality standards.

- Analyze surface roughness and other physical characteristics using microscopy and image analysis techniques.

- Monitor and evaluate process parameters to identify and correct deviations that could impact product quality.

- Collaborate with production teams to implement corrective actions and improve process efficiency.

- Develop and implement quality control procedures to ensure consistent and accurate inspection results.

- Train and supervise inspection personnel to maintain high levels of quality and productivity.

- Document inspection findings and prepare reports for management and customers.

Frequently Asked Questions (FAQ’s) For Texturing Process Quality Control Checker

What are the primary responsibilities of a Texturing Process Quality Control Checker?

The primary responsibilities of a Texturing Process Quality Control Checker include conducting visual, dimensional, and color inspections of textured surfaces, analyzing surface roughness and other physical characteristics, monitoring and evaluating process parameters, implementing and evaluating corrective actions, developing and implementing quality control procedures, and training and supervising inspection personnel.

What are the key skills and qualifications required for this role?

The key skills and qualifications required for a Texturing Process Quality Control Checker include visual inspection, dimensional inspection, color and appearance evaluation, surface roughness analysis, microscopy and image analysis, and statistical process control (SPC). A bachelor’s degree in materials science or a related field is also typically required.

What are the career prospects for Texturing Process Quality Control Checkers?

Texturing Process Quality Control Checkers with experience and expertise can advance to supervisory or management roles in quality control or related fields. They may also specialize in specific inspection techniques or focus on quality control in particular industries, such as semiconductors or manufacturing.

What is the expected salary range for this position?

The salary range for a Texturing Process Quality Control Checker can vary depending on experience, qualifications, and location. According to Glassdoor, the average salary for this role in the United States is around $65,000 per year.

What are some of the challenges that Texturing Process Quality Control Checkers face?

Some of the challenges that Texturing Process Quality Control Checkers may face include maintaining high levels of accuracy and consistency in inspections, keeping up with advancements in inspection techniques and technology, and ensuring that quality control processes are efficient and effective.