Are you a seasoned Thermal Surfacing Machine Operator seeking a new career path? Discover our professionally built Thermal Surfacing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

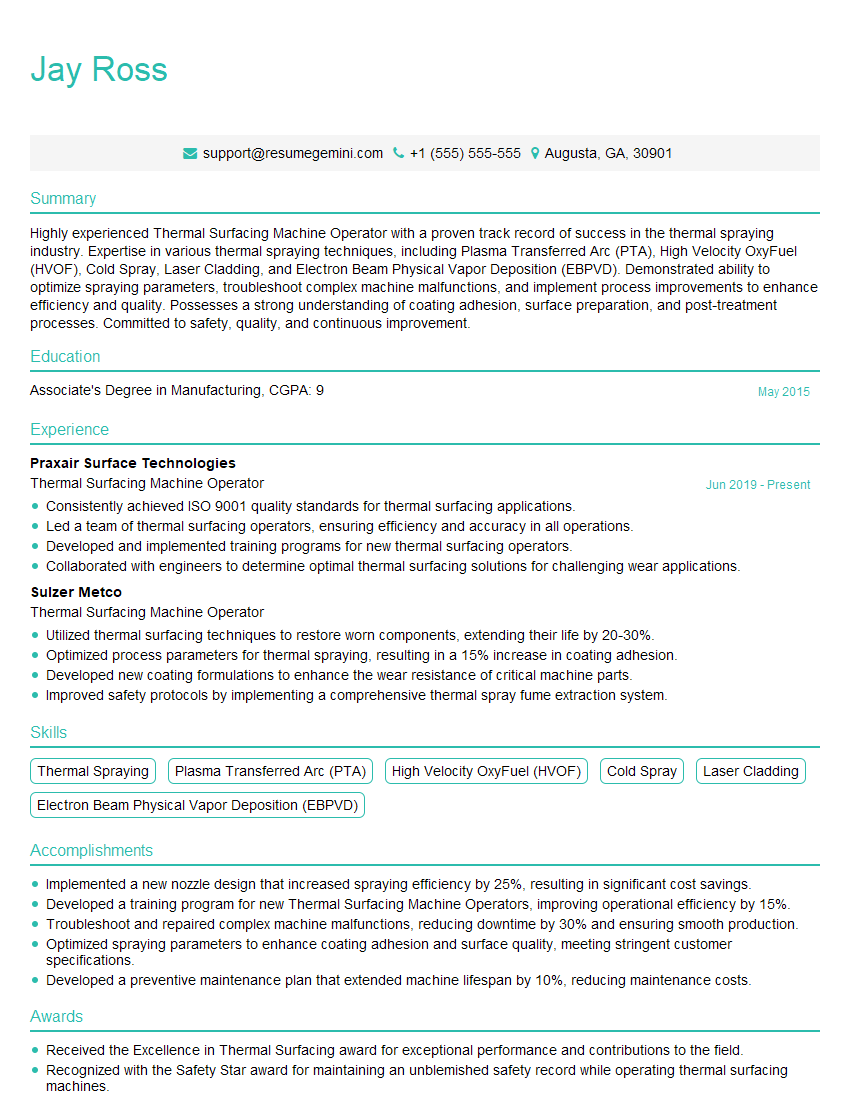

Jay Ross

Thermal Surfacing Machine Operator

Summary

Highly experienced Thermal Surfacing Machine Operator with a proven track record of success in the thermal spraying industry. Expertise in various thermal spraying techniques, including Plasma Transferred Arc (PTA), High Velocity OxyFuel (HVOF), Cold Spray, Laser Cladding, and Electron Beam Physical Vapor Deposition (EBPVD). Demonstrated ability to optimize spraying parameters, troubleshoot complex machine malfunctions, and implement process improvements to enhance efficiency and quality. Possesses a strong understanding of coating adhesion, surface preparation, and post-treatment processes. Committed to safety, quality, and continuous improvement.

Education

Associate’s Degree in Manufacturing

May 2015

Skills

- Thermal Spraying

- Plasma Transferred Arc (PTA)

- High Velocity OxyFuel (HVOF)

- Cold Spray

- Laser Cladding

- Electron Beam Physical Vapor Deposition (EBPVD)

Work Experience

Thermal Surfacing Machine Operator

- Consistently achieved ISO 9001 quality standards for thermal surfacing applications.

- Led a team of thermal surfacing operators, ensuring efficiency and accuracy in all operations.

- Developed and implemented training programs for new thermal surfacing operators.

- Collaborated with engineers to determine optimal thermal surfacing solutions for challenging wear applications.

Thermal Surfacing Machine Operator

- Utilized thermal surfacing techniques to restore worn components, extending their life by 20-30%.

- Optimized process parameters for thermal spraying, resulting in a 15% increase in coating adhesion.

- Developed new coating formulations to enhance the wear resistance of critical machine parts.

- Improved safety protocols by implementing a comprehensive thermal spray fume extraction system.

Accomplishments

- Implemented a new nozzle design that increased spraying efficiency by 25%, resulting in significant cost savings.

- Developed a training program for new Thermal Surfacing Machine Operators, improving operational efficiency by 15%.

- Troubleshoot and repaired complex machine malfunctions, reducing downtime by 30% and ensuring smooth production.

- Optimized spraying parameters to enhance coating adhesion and surface quality, meeting stringent customer specifications.

- Developed a preventive maintenance plan that extended machine lifespan by 10%, reducing maintenance costs.

Awards

- Received the Excellence in Thermal Surfacing award for exceptional performance and contributions to the field.

- Recognized with the Safety Star award for maintaining an unblemished safety record while operating thermal surfacing machines.

- Won the Golden Torch award for achieving the highest production targets among all Thermal Surfacing Machine Operators.

Certificates

- Certified Thermal Spray Engineer (CTSE)

- Certified Thermal Spray Inspector (CTSI)

- Certified Thermal Spray Technician (CTST)

- National Association of Surface Finishing (NASF) Coating Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Thermal Surfacing Machine Operator

- Highlight your experience with different thermal spraying techniques and your ability to select the appropriate coating for each application.

- Quantify your accomplishments with specific metrics, such as increased efficiency or reduced downtime.

- Showcase your problem-solving skills and ability to troubleshoot complex machine malfunctions.

- Emphasize your commitment to safety, quality, and continuous improvement.

- Tailor your resume to each job description, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Thermal Surfacing Machine Operator Resume

- Operate and maintain thermal surfacing machines, including plasma spray, HVOF, and cold spray systems.

- Select and apply appropriate thermal spray coatings based on customer specifications and application requirements.

- Monitor and control spraying parameters to ensure coating quality and adhesion.

- Troubleshoot and resolve machine malfunctions, ensuring minimal downtime and smooth production.

- Perform preventive maintenance and repairs on thermal surfacing equipment.

- Collaborate with engineers and technicians to optimize spraying processes and develop new applications.

- Adhere to safety regulations and industry standards to ensure a safe work environment.

Frequently Asked Questions (FAQ’s) For Thermal Surfacing Machine Operator

What are the key skills required to be a successful Thermal Surfacing Machine Operator?

Key skills for a Thermal Surfacing Machine Operator include expertise in thermal spraying techniques (PTA, HVOF, Cold Spray, Laser Cladding, EBPVD), machine operation and maintenance, troubleshooting, process optimization, coating adhesion, and surface preparation.

What industries use thermal surfacing?

Thermal surfacing is used in a wide range of industries, including aerospace, automotive, energy, manufacturing, and transportation. It is applied to enhance the properties of components, such as increasing wear resistance, corrosion resistance, and lifespan.

What are the different thermal spraying techniques?

Common thermal spraying techniques include Plasma Transferred Arc (PTA), High Velocity OxyFuel (HVOF), Cold Spray, Laser Cladding, and Electron Beam Physical Vapor Deposition (EBPVD). Each technique has its unique advantages and is suitable for different applications.

What are the career prospects for Thermal Surfacing Machine Operators?

Thermal Surfacing Machine Operators are in high demand due to the increasing use of thermal spraying in various industries. With experience and skill development, career advancement opportunities exist, such as becoming a Supervisor, Quality Control Inspector, or Process Engineer.

How can I improve my skills as a Thermal Surfacing Machine Operator?

To enhance your skills, consider attending industry workshops, obtaining certifications, and seeking opportunities to work on diverse projects. Stay updated with the latest advancements in thermal spraying technologies and best practices.

What is the salary range for Thermal Surfacing Machine Operators?

The salary range for Thermal Surfacing Machine Operators varies depending on experience, location, and industry. In the United States, the average salary is around $60,000 per year.