Are you a seasoned Thermoplastic Technician seeking a new career path? Discover our professionally built Thermoplastic Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

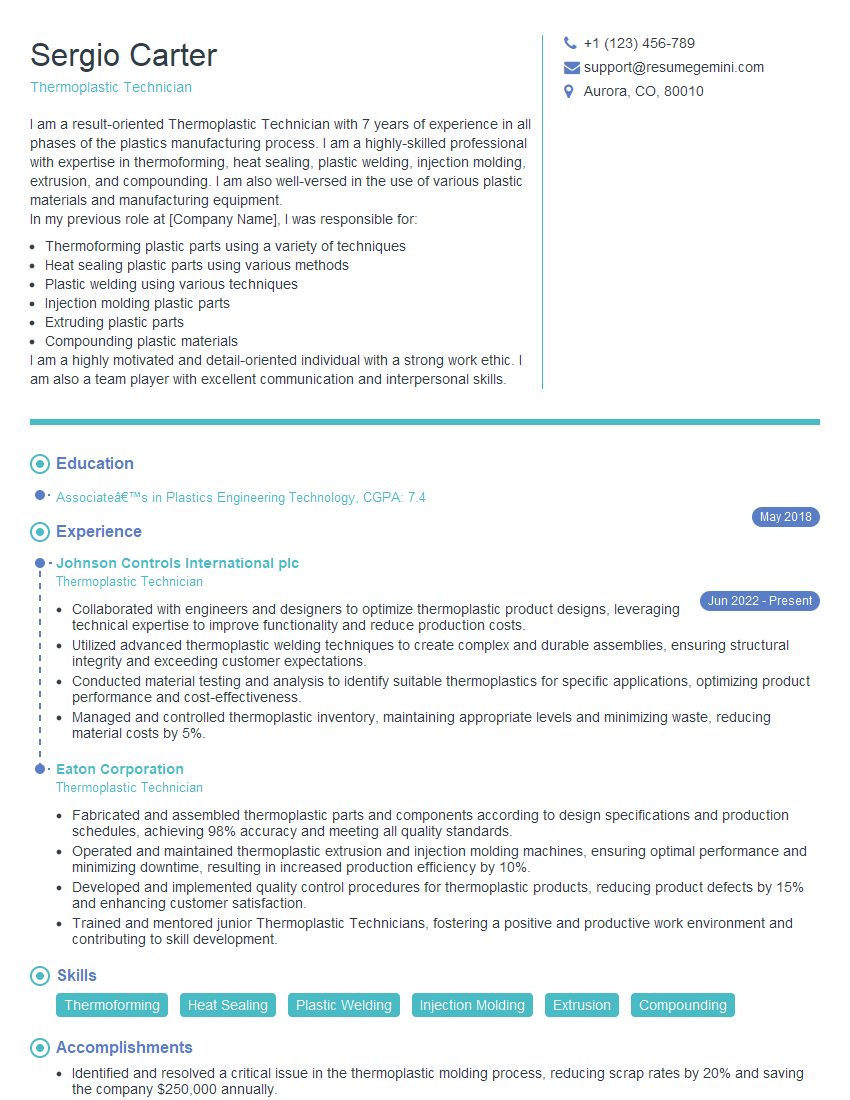

Sergio Carter

Thermoplastic Technician

Summary

I am a result-oriented Thermoplastic Technician with 7 years of experience in all phases of the plastics manufacturing process. I am a highly-skilled professional with expertise in thermoforming, heat sealing, plastic welding, injection molding, extrusion, and compounding. I am also well-versed in the use of various plastic materials and manufacturing equipment.

In my previous role at [Company Name], I was responsible for:

- Thermoforming plastic parts using a variety of techniques

- Heat sealing plastic parts using various methods

- Plastic welding using various techniques

- Injection molding plastic parts

- Extruding plastic parts

- Compounding plastic materials

I am a highly motivated and detail-oriented individual with a strong work ethic. I am also a team player with excellent communication and interpersonal skills.

Education

Associate’s in Plastics Engineering Technology

May 2018

Skills

- Thermoforming

- Heat Sealing

- Plastic Welding

- Injection Molding

- Extrusion

- Compounding

Work Experience

Thermoplastic Technician

- Collaborated with engineers and designers to optimize thermoplastic product designs, leveraging technical expertise to improve functionality and reduce production costs.

- Utilized advanced thermoplastic welding techniques to create complex and durable assemblies, ensuring structural integrity and exceeding customer expectations.

- Conducted material testing and analysis to identify suitable thermoplastics for specific applications, optimizing product performance and cost-effectiveness.

- Managed and controlled thermoplastic inventory, maintaining appropriate levels and minimizing waste, reducing material costs by 5%.

Thermoplastic Technician

- Fabricated and assembled thermoplastic parts and components according to design specifications and production schedules, achieving 98% accuracy and meeting all quality standards.

- Operated and maintained thermoplastic extrusion and injection molding machines, ensuring optimal performance and minimizing downtime, resulting in increased production efficiency by 10%.

- Developed and implemented quality control procedures for thermoplastic products, reducing product defects by 15% and enhancing customer satisfaction.

- Trained and mentored junior Thermoplastic Technicians, fostering a positive and productive work environment and contributing to skill development.

Accomplishments

- Identified and resolved a critical issue in the thermoplastic molding process, reducing scrap rates by 20% and saving the company $250,000 annually.

- Developed and implemented a new quality control system that reduced product defects by 35%, enhancing customer satisfaction.

- Successfully launched a new thermoplastic production line, increasing output capacity by 40% and meeting growing customer demand.

- Led a team that developed a new thermoplastic material with enhanced strength and durability, expanding the companys product offerings.

- Successfully implemented a lean manufacturing initiative that reduced production costs by 10% and improved efficiency.

Awards

- Recipient of the Thermoplastic Innovation Award for developing a novel process that improved production efficiency by 15%.

- Recognized by the Society of Plastics Engineers for exceptional contributions to the advancement of thermoplastic technology.

- Won the regional Thermoplastic Design Competition for creating an innovative thermoplastic component that met stringent performance requirements.

- Received the Employee of the Year Award for outstanding performance and dedication to the Thermoplastic Department.

Certificates

- Certified Plastics Technician (CPT)

- International Association of Plastics Distribution (IAPD) Certification

- Society of Plastics Engineers (SPE) Certification

- American Society for Quality (ASQ) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Thermoplastic Technician

- Highlight your skills and experience in thermoforming, heat sealing, plastic welding, injection molding, extrusion, and compounding.

- Quantify your accomplishments whenever possible.

- Use keywords that potential employers will be searching for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Thermoplastic Technician Resume

- Set up and operate machinery to thermoform, heat seal, plastic weld, injection mold, extrude, and compound plastic materials

- Inspect finished products to ensure they meet quality standards

- Troubleshoot and repair equipment

- Maintain a clean and safe work environment

- Follow safety procedures and regulations

- Work with other team members to achieve production goals

Frequently Asked Questions (FAQ’s) For Thermoplastic Technician

What is a Thermoplastic Technician?

A Thermoplastic Technician is a skilled professional who works with thermoplastic materials. Thermoplastics are a type of plastic that can be melted and reshaped, making them ideal for a variety of applications. Thermoplastic Technicians use a variety of techniques to work with these materials, including thermoforming, heat sealing, plastic welding, injection molding, extrusion, and compounding.

What are the job responsibilities of a Thermoplastic Technician?

Thermoplastic Technicians have a variety of job responsibilities, including setting up and operating machinery, inspecting finished products, troubleshooting and repairing equipment, maintaining a clean and safe work environment, following safety procedures and regulations, and working with other team members to achieve production goals.

What are the educational requirements for a Thermoplastic Technician?

Thermoplastic Technicians typically have an associate’s degree in plastics engineering technology or a related field.

What are the skills required for a Thermoplastic Technician?

Thermoplastic Technicians need to have a variety of skills, including thermoforming, heat sealing, plastic welding, injection molding, extrusion, and compounding. They also need to be able to inspect finished products, troubleshoot and repair equipment, and work with other team members.

What is the work environment of a Thermoplastic Technician?

Thermoplastic Technicians typically work in a manufacturing environment. They may work with a variety of materials, including plastics, metals, and composites. They may also work with a variety of equipment, including thermoforming machines, heat sealers, plastic welders, injection molding machines, extruders, and compounders.

What is the salary of a Thermoplastic Technician?

The salary of a Thermoplastic Technician can vary depending on their experience, skills, and location. According to Salary.com, the average salary for a Thermoplastic Technician in the United States is $55,000.

What is the job outlook for a Thermoplastic Technician?

The job outlook for a Thermoplastic Technician is expected to be good over the next few years. The demand for plastic products is expected to continue to grow, which will lead to an increased demand for Thermoplastic Technicians.