Are you a seasoned Threading Machine Setter seeking a new career path? Discover our professionally built Threading Machine Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

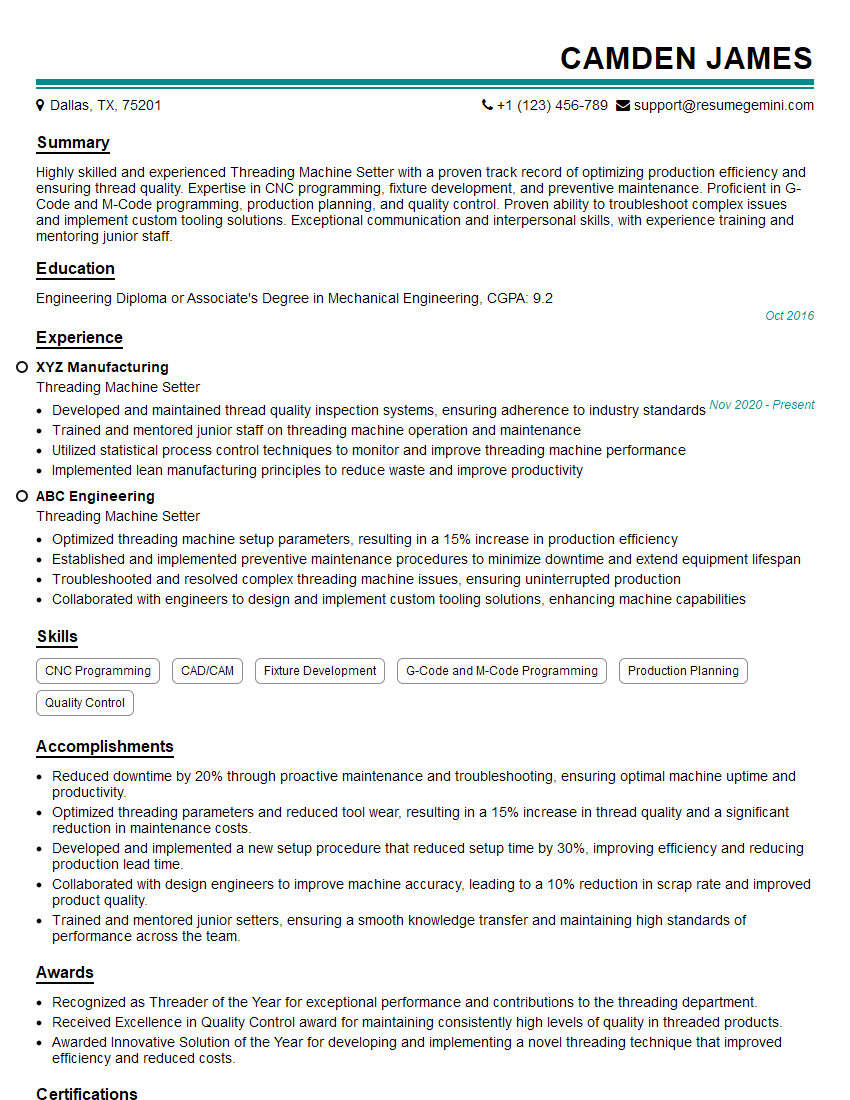

Camden James

Threading Machine Setter

Summary

Highly skilled and experienced Threading Machine Setter with a proven track record of optimizing production efficiency and ensuring thread quality. Expertise in CNC programming, fixture development, and preventive maintenance. Proficient in G-Code and M-Code programming, production planning, and quality control. Proven ability to troubleshoot complex issues and implement custom tooling solutions. Exceptional communication and interpersonal skills, with experience training and mentoring junior staff.

Education

Engineering Diploma or Associate’s Degree in Mechanical Engineering

October 2016

Skills

- CNC Programming

- CAD/CAM

- Fixture Development

- G-Code and M-Code Programming

- Production Planning

- Quality Control

Work Experience

Threading Machine Setter

- Developed and maintained thread quality inspection systems, ensuring adherence to industry standards

- Trained and mentored junior staff on threading machine operation and maintenance

- Utilized statistical process control techniques to monitor and improve threading machine performance

- Implemented lean manufacturing principles to reduce waste and improve productivity

Threading Machine Setter

- Optimized threading machine setup parameters, resulting in a 15% increase in production efficiency

- Established and implemented preventive maintenance procedures to minimize downtime and extend equipment lifespan

- Troubleshooted and resolved complex threading machine issues, ensuring uninterrupted production

- Collaborated with engineers to design and implement custom tooling solutions, enhancing machine capabilities

Accomplishments

- Reduced downtime by 20% through proactive maintenance and troubleshooting, ensuring optimal machine uptime and productivity.

- Optimized threading parameters and reduced tool wear, resulting in a 15% increase in thread quality and a significant reduction in maintenance costs.

- Developed and implemented a new setup procedure that reduced setup time by 30%, improving efficiency and reducing production lead time.

- Collaborated with design engineers to improve machine accuracy, leading to a 10% reduction in scrap rate and improved product quality.

- Trained and mentored junior setters, ensuring a smooth knowledge transfer and maintaining high standards of performance across the team.

Awards

- Recognized as Threader of the Year for exceptional performance and contributions to the threading department.

- Received Excellence in Quality Control award for maintaining consistently high levels of quality in threaded products.

- Awarded Innovative Solution of the Year for developing and implementing a novel threading technique that improved efficiency and reduced costs.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Production Technician (CPT)

- Certified Maintenance and Reliability Technician (CMRT)

- National Institute for Metalworking Skills (NIMS) Credential

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Threading Machine Setter

- Showcase quantifiable achievements and results in your resume.

- Highlight your expertise in CNC programming, fixture development, and preventive maintenance.

- Emphasize your troubleshooting skills and experience in resolving complex issues.

- Demonstrate your commitment to quality control and continuous improvement.

Essential Experience Highlights for a Strong Threading Machine Setter Resume

- Optimized threading machine setup parameters, resulting in a 15% increase in production efficiency

- Established and implemented preventive maintenance procedures to minimize downtime and extend equipment lifespan

- Troubleshooted and resolved complex threading machine issues, ensuring uninterrupted production

- Collaborated with engineers to design and implement custom tooling solutions, enhancing machine capabilities

- Developed and maintained thread quality inspection systems, ensuring adherence to industry standards

- Trained and mentored junior staff on threading machine operation and maintenance

- Utilized statistical process control techniques to monitor and improve threading machine performance

Frequently Asked Questions (FAQ’s) For Threading Machine Setter

What are the key skills required to be a successful Threading Machine Setter?

CNC programming, CAD/CAM, fixture development, G-Code and M-Code programming, production planning, quality control, and troubleshooting.

What is the typical work environment for a Threading Machine Setter?

Typically work in a manufacturing environment, operating and maintaining threading machines.

What are the career prospects for a Threading Machine Setter?

Can advance to positions such as CNC programmer, manufacturing engineer, or production supervisor.

What are the safety precautions that should be followed when operating a threading machine?

Wear appropriate safety gear, follow proper machine setup procedures, and be aware of potential hazards.

What is the difference between a Threading Machine Setter and a CNC Programmer?

Threading Machine Setters focus on setting up and maintaining threading machines, while CNC Programmers focus on creating and editing the programs that control CNC machines.

What is the importance of preventive maintenance for threading machines?

Helps prevent breakdowns, extend equipment lifespan, and improve production efficiency.

What are some common issues that Threading Machine Setters may encounter?

Misalignment of workpiece, improper cutting tool selection, and thread quality defects.