Are you a seasoned Tinning Equipment Tender seeking a new career path? Discover our professionally built Tinning Equipment Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

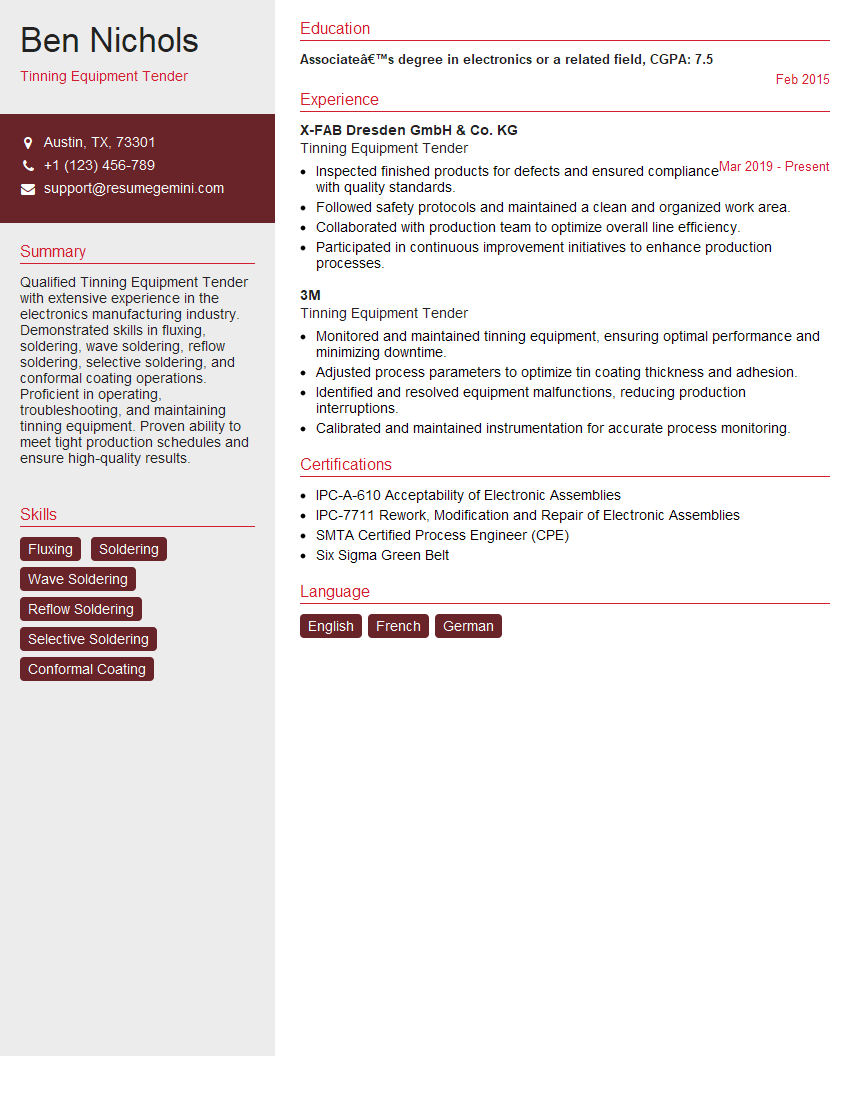

Ben Nichols

Tinning Equipment Tender

Summary

Qualified Tinning Equipment Tender with extensive experience in the electronics manufacturing industry. Demonstrated skills in fluxing, soldering, wave soldering, reflow soldering, selective soldering, and conformal coating operations. Proficient in operating, troubleshooting, and maintaining tinning equipment. Proven ability to meet tight production schedules and ensure high-quality results.

Education

Associate’s degree in electronics or a related field

February 2015

Skills

- Fluxing

- Soldering

- Wave Soldering

- Reflow Soldering

- Selective Soldering

- Conformal Coating

Work Experience

Tinning Equipment Tender

- Inspected finished products for defects and ensured compliance with quality standards.

- Followed safety protocols and maintained a clean and organized work area.

- Collaborated with production team to optimize overall line efficiency.

- Participated in continuous improvement initiatives to enhance production processes.

Tinning Equipment Tender

- Monitored and maintained tinning equipment, ensuring optimal performance and minimizing downtime.

- Adjusted process parameters to optimize tin coating thickness and adhesion.

- Identified and resolved equipment malfunctions, reducing production interruptions.

- Calibrated and maintained instrumentation for accurate process monitoring.

Certificates

- IPC-A-610 Acceptability of Electronic Assemblies

- IPC-7711 Rework, Modification and Repair of Electronic Assemblies

- SMTA Certified Process Engineer (CPE)

- Six Sigma Green Belt

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tinning Equipment Tender

- Highlight your experience in operating and maintaining tinning equipment.

- Showcase your skills in fluxing, soldering, and other tinning processes.

- Provide examples of your ability to troubleshoot and resolve equipment issues.

- Quantify your accomplishments by providing specific metrics or results.

- Tailor your resume to the specific job requirements of each position you apply for.

Essential Experience Highlights for a Strong Tinning Equipment Tender Resume

- Operate and maintain tinning equipment, ensuring optimal performance and efficiency.

- Inspect and prepare materials and components for tinning.

- Review and interpret technical specifications and drawings to determine equipment settings and process parameters.

- Program and control tinning equipment to achieve desired results.

- Monitor and adjust equipment to ensure adherence to quality standards.

- Troubleshoot and resolve equipment malfunctions and downtime.

- Maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Tinning Equipment Tender

What is tinning equipment?

Tinning equipment is used to apply a thin layer of tin or other metal to the surface of a metal object. This process is often used to improve the solderability of the metal surface or to protect it from corrosion.

What are the different types of tinning equipment?

There are many different types of tinning equipment, including manual tinning machines, semi-automatic tinning machines, and fully automatic tinning machines.

What are the benefits of using tinning equipment?

Tinning equipment can provide a number of benefits, including improved solderability, corrosion protection, and increased electrical conductivity.

What are the challenges of using tinning equipment?

Some of the challenges of using tinning equipment include the need for proper training, the potential for solder defects, and the need for proper maintenance.

What are the safety precautions that should be taken when using tinning equipment?

Some of the safety precautions that should be taken when using tinning equipment include wearing proper protective clothing, using adequate ventilation, and following all manufacturer’s instructions.

What is the future of tinning equipment?

The future of tinning equipment is expected to be bright, as the demand for tinning services is expected to increase in the coming years.

What are the career opportunities for Tinning Equipment Tenders?

Tinning Equipment Tenders can find employment opportunities in a variety of industries, including electronics manufacturing, automotive, and aerospace.