Are you a seasoned Tip Finisher seeking a new career path? Discover our professionally built Tip Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

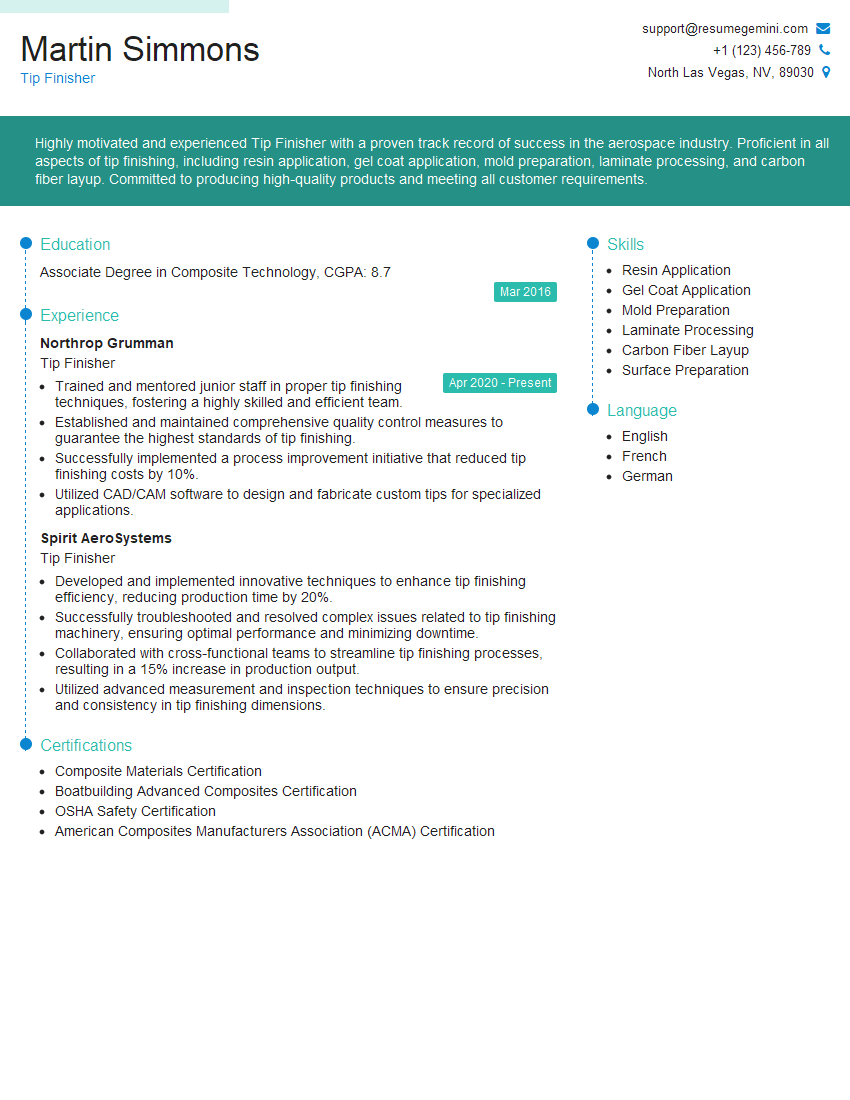

Martin Simmons

Tip Finisher

Summary

Highly motivated and experienced Tip Finisher with a proven track record of success in the aerospace industry. Proficient in all aspects of tip finishing, including resin application, gel coat application, mold preparation, laminate processing, and carbon fiber layup. Committed to producing high-quality products and meeting all customer requirements.

Education

Associate Degree in Composite Technology

March 2016

Skills

- Resin Application

- Gel Coat Application

- Mold Preparation

- Laminate Processing

- Carbon Fiber Layup

- Surface Preparation

Work Experience

Tip Finisher

- Trained and mentored junior staff in proper tip finishing techniques, fostering a highly skilled and efficient team.

- Established and maintained comprehensive quality control measures to guarantee the highest standards of tip finishing.

- Successfully implemented a process improvement initiative that reduced tip finishing costs by 10%.

- Utilized CAD/CAM software to design and fabricate custom tips for specialized applications.

Tip Finisher

- Developed and implemented innovative techniques to enhance tip finishing efficiency, reducing production time by 20%.

- Successfully troubleshooted and resolved complex issues related to tip finishing machinery, ensuring optimal performance and minimizing downtime.

- Collaborated with cross-functional teams to streamline tip finishing processes, resulting in a 15% increase in production output.

- Utilized advanced measurement and inspection techniques to ensure precision and consistency in tip finishing dimensions.

Certificates

- Composite Materials Certification

- Boatbuilding Advanced Composites Certification

- OSHA Safety Certification

- American Composites Manufacturers Association (ACMA) Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tip Finisher

- Highlight your skills and experience in tip finishing in your resume summary.

- Use keywords throughout your resume to make it more visible to potential employers.

- Showcase your ability to produce high-quality products and meet customer requirements.

- Emphasize your attention to detail and commitment to safety.

- Proofread your resume carefully before submitting it to potential employers.

Essential Experience Highlights for a Strong Tip Finisher Resume

- Prepare molds and layups for composite fabrication

- Apply resin and gel coat to molds and laminates

- Cure and trim composite parts

- Inspect and test finished parts to ensure they meet specifications

- Maintain a clean and organized work area

- Follow all safety procedures and regulations

- Work independently and as part of a team

Frequently Asked Questions (FAQ’s) For Tip Finisher

What is a Tip Finisher?

A Tip Finisher is a skilled technician who specializes in the finishing of composite parts, such as those used in the aerospace industry. Tip Finishers are responsible for applying resin and gel coat to molds and laminates, curing and trimming composite parts, and inspecting and testing finished parts to ensure they meet specifications.

What are the qualifications for becoming a Tip Finisher?

Most Tip Finishers have an associate degree in composite technology or a related field. They also have experience in working with composite materials, such as fiberglass and carbon fiber. Tip Finishers must be able to read and follow instructions, work independently, and pay attention to detail.

What are the responsibilities of a Tip Finisher?

Tip Finishers are responsible for preparing molds and layups for composite fabrication, applying resin and gel coat to molds and laminates, curing and trimming composite parts, inspecting and testing finished parts to ensure they meet specifications, and maintaining a clean and organized work area.

What are the skills required to become a Tip Finisher?

Tip Finishers must have strong skills in working with composite materials, such as fiberglass and carbon fiber. They also need to be able to read and follow instructions, work independently, and pay attention to detail. Tip Finishers must also be able to work in a team environment and follow safety procedures.

What is the job outlook for Tip Finishers?

The job outlook for Tip Finishers is expected to be good over the next few years. The aerospace industry is growing, and this is expected to lead to an increased demand for Tip Finishers. Tip Finishers with experience in working with carbon fiber composites are expected to be in high demand.

What are the benefits of becoming a Tip Finisher?

Tip Finishers can enjoy a number of benefits, including competitive salaries, good working conditions, and the opportunity to work on cutting-edge technology. Tip Finishers also have the opportunity to advance their careers by becoming supervisors or managers.