Are you a seasoned Tool and Die Repair seeking a new career path? Discover our professionally built Tool and Die Repair Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

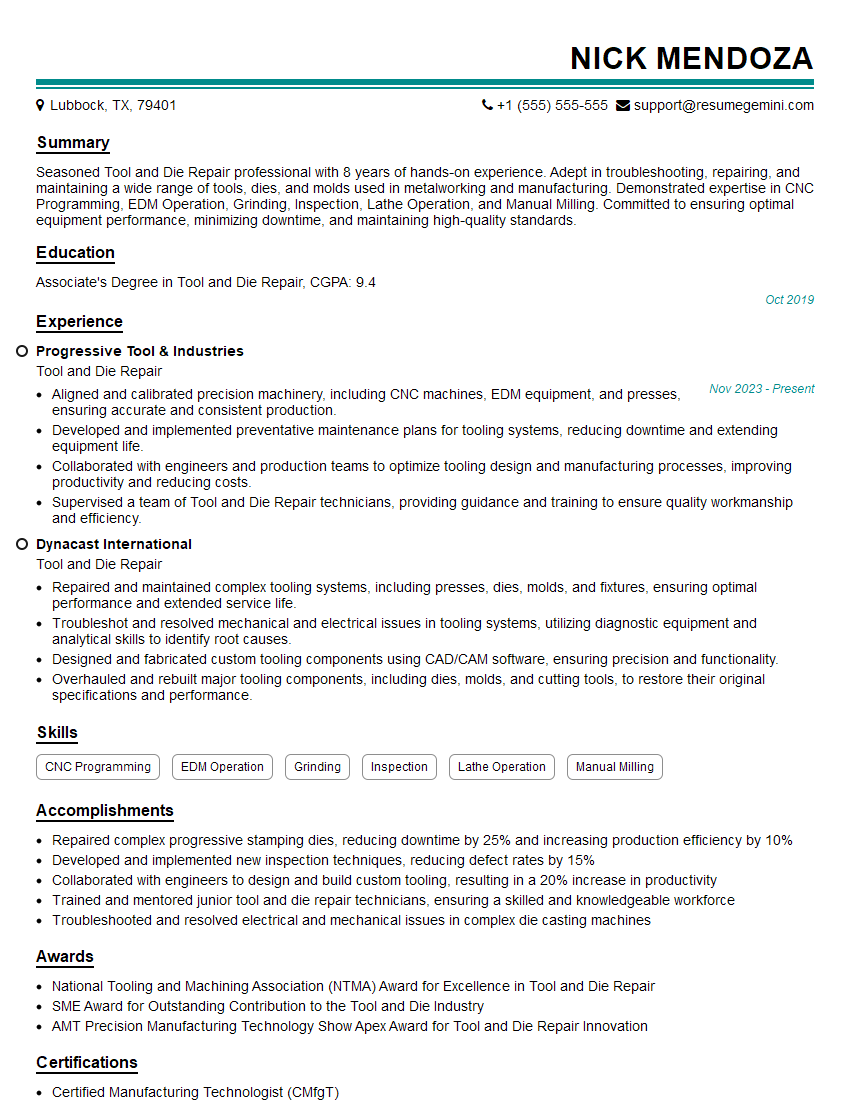

Nick Mendoza

Tool and Die Repair

Summary

Seasoned Tool and Die Repair professional with 8 years of hands-on experience. Adept in troubleshooting, repairing, and maintaining a wide range of tools, dies, and molds used in metalworking and manufacturing. Demonstrated expertise in CNC Programming, EDM Operation, Grinding, Inspection, Lathe Operation, and Manual Milling. Committed to ensuring optimal equipment performance, minimizing downtime, and maintaining high-quality standards.

Education

Associate’s Degree in Tool and Die Repair

October 2019

Skills

- CNC Programming

- EDM Operation

- Grinding

- Inspection

- Lathe Operation

- Manual Milling

Work Experience

Tool and Die Repair

- Aligned and calibrated precision machinery, including CNC machines, EDM equipment, and presses, ensuring accurate and consistent production.

- Developed and implemented preventative maintenance plans for tooling systems, reducing downtime and extending equipment life.

- Collaborated with engineers and production teams to optimize tooling design and manufacturing processes, improving productivity and reducing costs.

- Supervised a team of Tool and Die Repair technicians, providing guidance and training to ensure quality workmanship and efficiency.

Tool and Die Repair

- Repaired and maintained complex tooling systems, including presses, dies, molds, and fixtures, ensuring optimal performance and extended service life.

- Troubleshot and resolved mechanical and electrical issues in tooling systems, utilizing diagnostic equipment and analytical skills to identify root causes.

- Designed and fabricated custom tooling components using CAD/CAM software, ensuring precision and functionality.

- Overhauled and rebuilt major tooling components, including dies, molds, and cutting tools, to restore their original specifications and performance.

Accomplishments

- Repaired complex progressive stamping dies, reducing downtime by 25% and increasing production efficiency by 10%

- Developed and implemented new inspection techniques, reducing defect rates by 15%

- Collaborated with engineers to design and build custom tooling, resulting in a 20% increase in productivity

- Trained and mentored junior tool and die repair technicians, ensuring a skilled and knowledgeable workforce

- Troubleshooted and resolved electrical and mechanical issues in complex die casting machines

Awards

- National Tooling and Machining Association (NTMA) Award for Excellence in Tool and Die Repair

- SME Award for Outstanding Contribution to the Tool and Die Industry

- AMT Precision Manufacturing Technology Show Apex Award for Tool and Die Repair Innovation

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Mold Maker (CMM)

- Certified Tool and Die Maker (CTDM)

- CNC Programming Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Die Repair

- Highlight your skills and experience in CNC Programming, EDM Operation, and other relevant areas.

- Showcase your ability to work independently and as part of a team in a fast-paced environment.

- Demonstrate your commitment to safety and adherence to industry standards.

- Quantify your accomplishments with specific metrics and examples, such as reducing downtime or improving production efficiency.

Essential Experience Highlights for a Strong Tool and Die Repair Resume

- Troubleshoot and repair faulty tools, dies, and molds, restoring them to optimal operating condition.

- Inspect and evaluate tools and equipment using precision measuring instruments to ensure dimensional accuracy.

- Perform preventive maintenance and make necessary adjustments to prevent equipment failures and extend tool life.

- Operate a variety of CNC machines, including lathes, mills, and EDM equipment, to machine complex parts and components.

- Diagnose electrical and mechanical problems with tools and dies, using specialized tools and techniques.

- Collaborate with engineers and operators to identify and resolve production issues, ensuring efficient and consistent operation.

- Maintain a clean and organized work area, adhering to all safety regulations and industry best practices.

Frequently Asked Questions (FAQ’s) For Tool and Die Repair

What are the key skills required for a Tool and Die Repair professional?

Key skills include CNC Programming, EDM Operation, Grinding, Inspection, Lathe Operation, Manual Milling, and a strong understanding of mechanical and electrical systems.

What industries employ Tool and Die Repair professionals?

Tool and Die Repair professionals are employed in various industries, including automotive, aerospace, electronics, and manufacturing.

What are the career prospects for Tool and Die Repair professionals?

Tool and Die Repair professionals are in high demand due to the increasing use of automated equipment and the need for precision manufacturing. Career prospects include advancement to lead roles, such as Tool and Die Maker or Manufacturing Supervisor.

What is the average salary for a Tool and Die Repair professional?

The average salary for a Tool and Die Repair professional varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers was $56,980 in May 2020.

What type of education and training is required for a Tool and Die Repair professional?

Most Tool and Die Repair professionals have an Associate’s Degree in Tool and Die Repair or a related field. Additionally, many employers provide on-the-job training and apprenticeship programs.

Is Tool and Die Repair a physically demanding job?

Yes, Tool and Die Repair can be physically demanding. It involves working with heavy equipment, standing for extended periods, and performing repetitive tasks.

What are the safety precautions that Tool and Die Repair professionals must follow?

Tool and Die Repair professionals must follow strict safety precautions, including wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and adhering to established safety protocols.

What is the job outlook for Tool and Die Repair professionals?

The job outlook for Tool and Die Repair professionals is expected to be positive in the coming years. The increasing use of automation and the need for precision manufacturing will continue to drive demand for skilled professionals in this field.