Are you a seasoned Tool and Die Technician seeking a new career path? Discover our professionally built Tool and Die Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

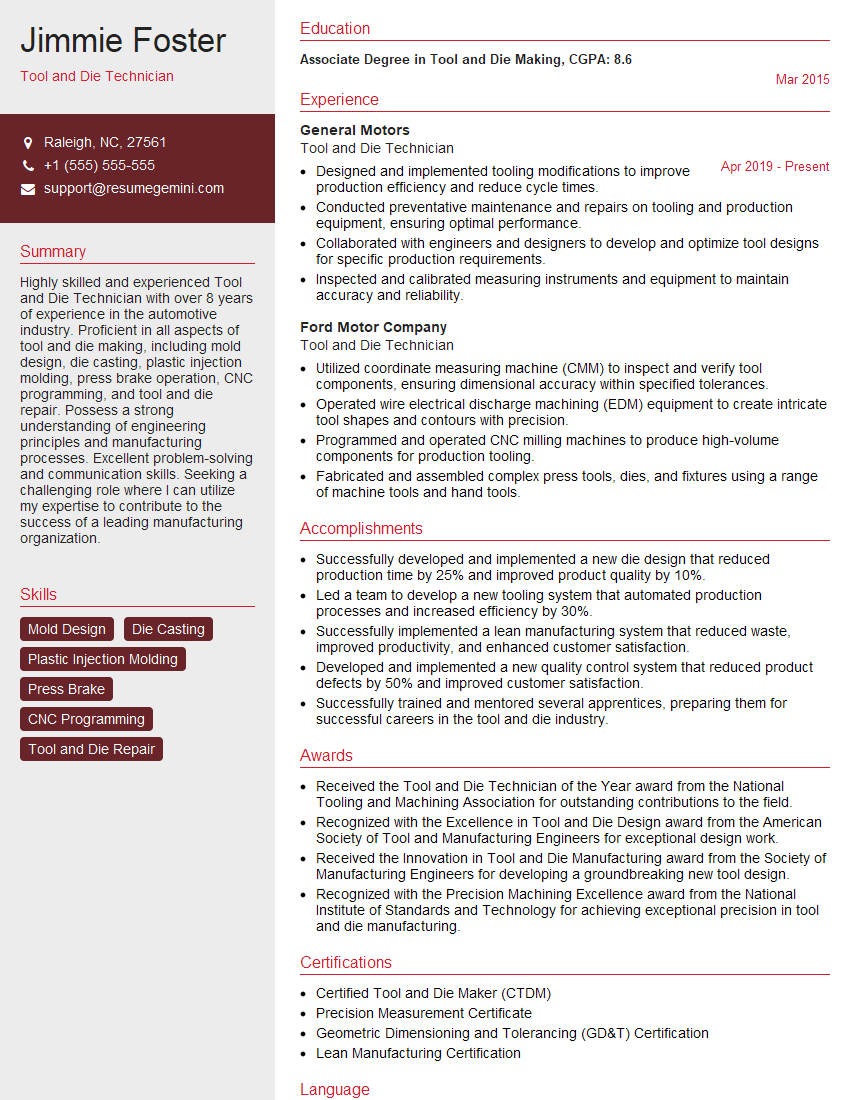

Jimmie Foster

Tool and Die Technician

Summary

Highly skilled and experienced Tool and Die Technician with over 8 years of experience in the automotive industry. Proficient in all aspects of tool and die making, including mold design, die casting, plastic injection molding, press brake operation, CNC programming, and tool and die repair. Possess a strong understanding of engineering principles and manufacturing processes. Excellent problem-solving and communication skills. Seeking a challenging role where I can utilize my expertise to contribute to the success of a leading manufacturing organization.

Education

Associate Degree in Tool and Die Making

March 2015

Skills

- Mold Design

- Die Casting

- Plastic Injection Molding

- Press Brake

- CNC Programming

- Tool and Die Repair

Work Experience

Tool and Die Technician

- Designed and implemented tooling modifications to improve production efficiency and reduce cycle times.

- Conducted preventative maintenance and repairs on tooling and production equipment, ensuring optimal performance.

- Collaborated with engineers and designers to develop and optimize tool designs for specific production requirements.

- Inspected and calibrated measuring instruments and equipment to maintain accuracy and reliability.

Tool and Die Technician

- Utilized coordinate measuring machine (CMM) to inspect and verify tool components, ensuring dimensional accuracy within specified tolerances.

- Operated wire electrical discharge machining (EDM) equipment to create intricate tool shapes and contours with precision.

- Programmed and operated CNC milling machines to produce high-volume components for production tooling.

- Fabricated and assembled complex press tools, dies, and fixtures using a range of machine tools and hand tools.

Accomplishments

- Successfully developed and implemented a new die design that reduced production time by 25% and improved product quality by 10%.

- Led a team to develop a new tooling system that automated production processes and increased efficiency by 30%.

- Successfully implemented a lean manufacturing system that reduced waste, improved productivity, and enhanced customer satisfaction.

- Developed and implemented a new quality control system that reduced product defects by 50% and improved customer satisfaction.

- Successfully trained and mentored several apprentices, preparing them for successful careers in the tool and die industry.

Awards

- Received the Tool and Die Technician of the Year award from the National Tooling and Machining Association for outstanding contributions to the field.

- Recognized with the Excellence in Tool and Die Design award from the American Society of Tool and Manufacturing Engineers for exceptional design work.

- Received the Innovation in Tool and Die Manufacturing award from the Society of Manufacturing Engineers for developing a groundbreaking new tool design.

- Recognized with the Precision Machining Excellence award from the National Institute of Standards and Technology for achieving exceptional precision in tool and die manufacturing.

Certificates

- Certified Tool and Die Maker (CTDM)

- Precision Measurement Certificate

- Geometric Dimensioning and Tolerancing (GD&T) Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Die Technician

- Highlight your skills and experience in mold design, die casting, plastic injection molding, press brake operation, CNC programming, and tool and die repair.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or punctuation.

Essential Experience Highlights for a Strong Tool and Die Technician Resume

- Designed and developed molds and dies for various automotive components, including body panels, interior parts, and engine components.

- Operated CNC machines to manufacture molds and dies to precise specifications.

- Set up and operated press brakes to form sheet metal components.

- Programmed and operated CNC machines for tool and die repair.

- Inspected and maintained tools and dies to ensure optimal performance.

- Collaborated with engineers and designers to develop and improve tooling processes.

- Provided technical support to production staff on tool and die related issues.

Frequently Asked Questions (FAQ’s) For Tool and Die Technician

What is the job outlook for tool and die technicians?

The job outlook for tool and die technicians is expected to be good over the next several years. The demand for skilled tool and die technicians is expected to increase as manufacturers continue to invest in new technologies and products.

What are the educational requirements for becoming a tool and die technician?

Most tool and die technicians have a high school diploma or equivalent. However, some employers may prefer candidates with an associate degree in tool and die making or a related field.

What are the key skills and abilities required for tool and die technicians?

Key skills and abilities required for tool and die technicians include: Strong math and science skills, ability to read and interpret blueprints, proficiency in the use of CNC machines and other machine tools, problem-solving skills, attention to detail, and manual dexterity.

What is the average salary for tool and die technicians?

The average salary for tool and die technicians varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for tool and die makers was $56,530 in May 2021.

What are the career advancement opportunities for tool and die technicians?

Tool and die technicians with experience and additional training may advance to supervisory or management positions. They may also become involved in product design and development.