Are you a seasoned Tool and Fixture Repairer seeking a new career path? Discover our professionally built Tool and Fixture Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

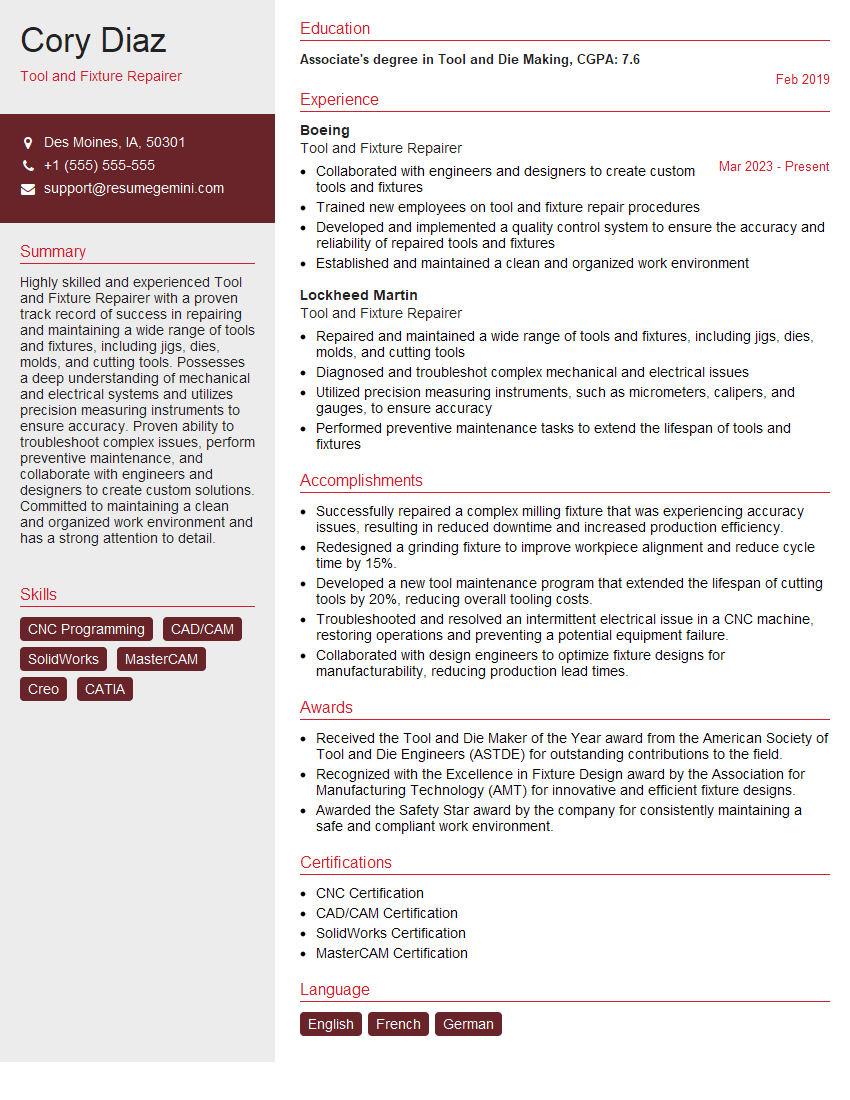

Cory Diaz

Tool and Fixture Repairer

Summary

Highly skilled and experienced Tool and Fixture Repairer with a proven track record of success in repairing and maintaining a wide range of tools and fixtures, including jigs, dies, molds, and cutting tools. Possesses a deep understanding of mechanical and electrical systems and utilizes precision measuring instruments to ensure accuracy. Proven ability to troubleshoot complex issues, perform preventive maintenance, and collaborate with engineers and designers to create custom solutions. Committed to maintaining a clean and organized work environment and has a strong attention to detail.

Education

Associate’s degree in Tool and Die Making

February 2019

Skills

- CNC Programming

- CAD/CAM

- SolidWorks

- MasterCAM

- Creo

- CATIA

Work Experience

Tool and Fixture Repairer

- Collaborated with engineers and designers to create custom tools and fixtures

- Trained new employees on tool and fixture repair procedures

- Developed and implemented a quality control system to ensure the accuracy and reliability of repaired tools and fixtures

- Established and maintained a clean and organized work environment

Tool and Fixture Repairer

- Repaired and maintained a wide range of tools and fixtures, including jigs, dies, molds, and cutting tools

- Diagnosed and troubleshot complex mechanical and electrical issues

- Utilized precision measuring instruments, such as micrometers, calipers, and gauges, to ensure accuracy

- Performed preventive maintenance tasks to extend the lifespan of tools and fixtures

Accomplishments

- Successfully repaired a complex milling fixture that was experiencing accuracy issues, resulting in reduced downtime and increased production efficiency.

- Redesigned a grinding fixture to improve workpiece alignment and reduce cycle time by 15%.

- Developed a new tool maintenance program that extended the lifespan of cutting tools by 20%, reducing overall tooling costs.

- Troubleshooted and resolved an intermittent electrical issue in a CNC machine, restoring operations and preventing a potential equipment failure.

- Collaborated with design engineers to optimize fixture designs for manufacturability, reducing production lead times.

Awards

- Received the Tool and Die Maker of the Year award from the American Society of Tool and Die Engineers (ASTDE) for outstanding contributions to the field.

- Recognized with the Excellence in Fixture Design award by the Association for Manufacturing Technology (AMT) for innovative and efficient fixture designs.

- Awarded the Safety Star award by the company for consistently maintaining a safe and compliant work environment.

Certificates

- CNC Certification

- CAD/CAM Certification

- SolidWorks Certification

- MasterCAM Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Fixture Repairer

- Highlight your technical skills and experience in tool and fixture repair, including specific tools and techniques.

- Quantify your accomplishments with specific metrics, such as the number of tools repaired or the percentage of downtime reduced.

- Demonstrate your problem-solving abilities and provide examples of how you have resolved complex issues.

- Emphasize your commitment to quality and safety by describing your quality control procedures and safety practices.

Essential Experience Highlights for a Strong Tool and Fixture Repairer Resume

- Diagnose and troubleshoot complex mechanical and electrical issues in tools and fixtures.

- Utilize precision measuring instruments, such as micrometers, calipers, and gauges, to ensure accuracy in repairs.

- Perform preventive maintenance tasks to extend the lifespan of tools and fixtures, minimizing downtime.

- Collaborate with engineers and designers to create custom tools and fixtures, optimizing production processes.

- Train new employees on tool and fixture repair procedures, ensuring a skilled workforce.

- Develop and implement a quality control system to ensure the accuracy and reliability of repaired tools and fixtures.

- Maintain a clean and organized work environment, adhering to safety regulations and best practices.

Frequently Asked Questions (FAQ’s) For Tool and Fixture Repairer

What are the educational requirements to become a Tool and Fixture Repairer?

Typically, an associate’s degree in Tool and Die Making or a related field is required.

What are the key skills required for a successful Tool and Fixture Repairer?

Strong mechanical and electrical knowledge, precision measuring skills, problem-solving abilities, and attention to detail are essential.

What are the career prospects for Tool and Fixture Repairers?

With experience, Tool and Fixture Repairers can advance to supervisory roles or specialize in specific areas, such as CNC programming or tool design.

What is the work environment like for Tool and Fixture Repairers?

Tool and Fixture Repairers typically work in manufacturing facilities or repair shops, in a hands-on environment with potential exposure to noise, dust, and machinery.

What are the safety precautions that Tool and Fixture Repairers must follow?

Adherence to safety regulations, proper use of personal protective equipment, and maintaining a clean and organized work environment are crucial for the safety of Tool and Fixture Repairers.