Are you a seasoned Tool Gear Cutting Machine Set-Up Operator seeking a new career path? Discover our professionally built Tool Gear Cutting Machine Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

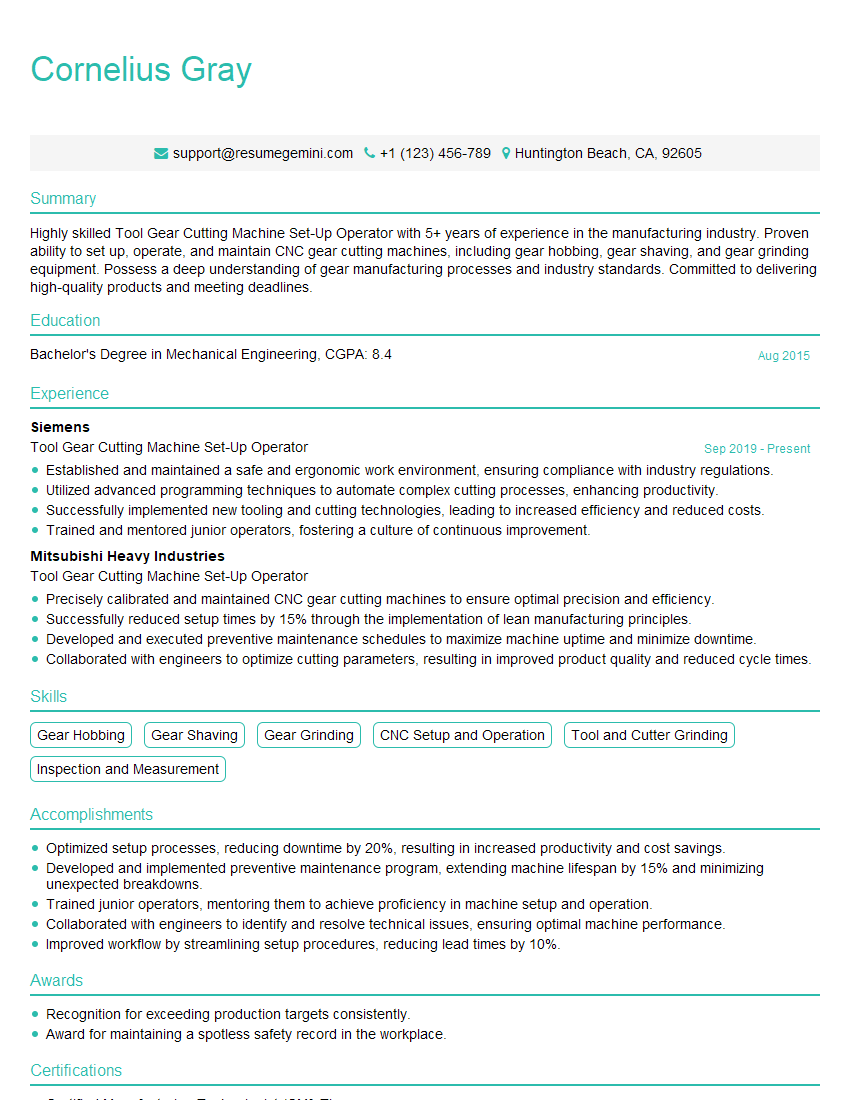

Cornelius Gray

Tool Gear Cutting Machine Set-Up Operator

Summary

Highly skilled Tool Gear Cutting Machine Set-Up Operator with 5+ years of experience in the manufacturing industry. Proven ability to set up, operate, and maintain CNC gear cutting machines, including gear hobbing, gear shaving, and gear grinding equipment. Possess a deep understanding of gear manufacturing processes and industry standards. Committed to delivering high-quality products and meeting deadlines.

Education

Bachelor’s Degree in Mechanical Engineering

August 2015

Skills

- Gear Hobbing

- Gear Shaving

- Gear Grinding

- CNC Setup and Operation

- Tool and Cutter Grinding

- Inspection and Measurement

Work Experience

Tool Gear Cutting Machine Set-Up Operator

- Established and maintained a safe and ergonomic work environment, ensuring compliance with industry regulations.

- Utilized advanced programming techniques to automate complex cutting processes, enhancing productivity.

- Successfully implemented new tooling and cutting technologies, leading to increased efficiency and reduced costs.

- Trained and mentored junior operators, fostering a culture of continuous improvement.

Tool Gear Cutting Machine Set-Up Operator

- Precisely calibrated and maintained CNC gear cutting machines to ensure optimal precision and efficiency.

- Successfully reduced setup times by 15% through the implementation of lean manufacturing principles.

- Developed and executed preventive maintenance schedules to maximize machine uptime and minimize downtime.

- Collaborated with engineers to optimize cutting parameters, resulting in improved product quality and reduced cycle times.

Accomplishments

- Optimized setup processes, reducing downtime by 20%, resulting in increased productivity and cost savings.

- Developed and implemented preventive maintenance program, extending machine lifespan by 15% and minimizing unexpected breakdowns.

- Trained junior operators, mentoring them to achieve proficiency in machine setup and operation.

- Collaborated with engineers to identify and resolve technical issues, ensuring optimal machine performance.

- Improved workflow by streamlining setup procedures, reducing lead times by 10%.

Awards

- Recognition for exceeding production targets consistently.

- Award for maintaining a spotless safety record in the workplace.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- National Institute for Metalworking Skills (NIMS)

- OSHA 30-Hour General Industry Safety

- AWS Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Gear Cutting Machine Set-Up Operator

- Highlight your experience and skills in gear manufacturing, including specific machine types and processes.

- Quantify your accomplishments with specific metrics, such as increased productivity or reduced downtime.

- Demonstrate your knowledge of industry standards and best practices.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Tool Gear Cutting Machine Set-Up Operator Resume

- Set up and operate CNC gear cutting machines, including gear hobbing, gear shaving, and gear grinding equipment.

- Program and troubleshoot CNC machines to ensure optimal performance and precision.

- Inspect and measure gears to ensure they meet specifications and quality standards.

- Maintain and repair CNC machines to minimize downtime and maximize productivity.

- Collaborate with engineers and other team members to develop and implement process improvements.

- Follow safety protocols and maintain a clean and organized work area.

- Stay up-to-date on industry best practices and advancements in gear manufacturing technology.

Frequently Asked Questions (FAQ’s) For Tool Gear Cutting Machine Set-Up Operator

What are the primary responsibilities of a Tool Gear Cutting Machine Set-Up Operator?

The primary responsibilities include setting up, operating, and maintaining CNC gear cutting machines, programming and troubleshooting CNC machines, inspecting and measuring gears, maintaining and repairing CNC machines, and collaborating with engineers and other team members.

What skills are required to be successful as a Tool Gear Cutting Machine Set-Up Operator?

Essential skills include knowledge of gear manufacturing processes, experience with CNC gear cutting machines, understanding of industry standards, proficiency in inspection and measurement techniques, and strong troubleshooting abilities.

What is the average salary for a Tool Gear Cutting Machine Set-Up Operator?

The average salary can vary depending on experience, location, and industry, but it typically ranges from $40,000 to $60,000 per year.

What are the career advancement opportunities for a Tool Gear Cutting Machine Set-Up Operator?

With experience and additional training, Tool Gear Cutting Machine Set-Up Operators can advance to roles such as CNC programmer, manufacturing engineer, or quality control inspector.

What is the job outlook for Tool Gear Cutting Machine Set-Up Operators?

The job outlook is expected to be positive as there is a growing demand for skilled manufacturing professionals.

What are the educational requirements for a Tool Gear Cutting Machine Set-Up Operator?

While formal education is not always required, many employers prefer candidates with a high school diploma or equivalent, along with specialized training in gear manufacturing or CNC machining.

What are the safety protocols that Tool Gear Cutting Machine Set-Up Operators must follow?

Operators must adhere to established safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

What are the key qualities of a successful Tool Gear Cutting Machine Set-Up Operator?

Successful operators possess a strong attention to detail, problem-solving abilities, and a commitment to delivering high-quality products.