Are you a seasoned Tool Machine Setup Operator seeking a new career path? Discover our professionally built Tool Machine Setup Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

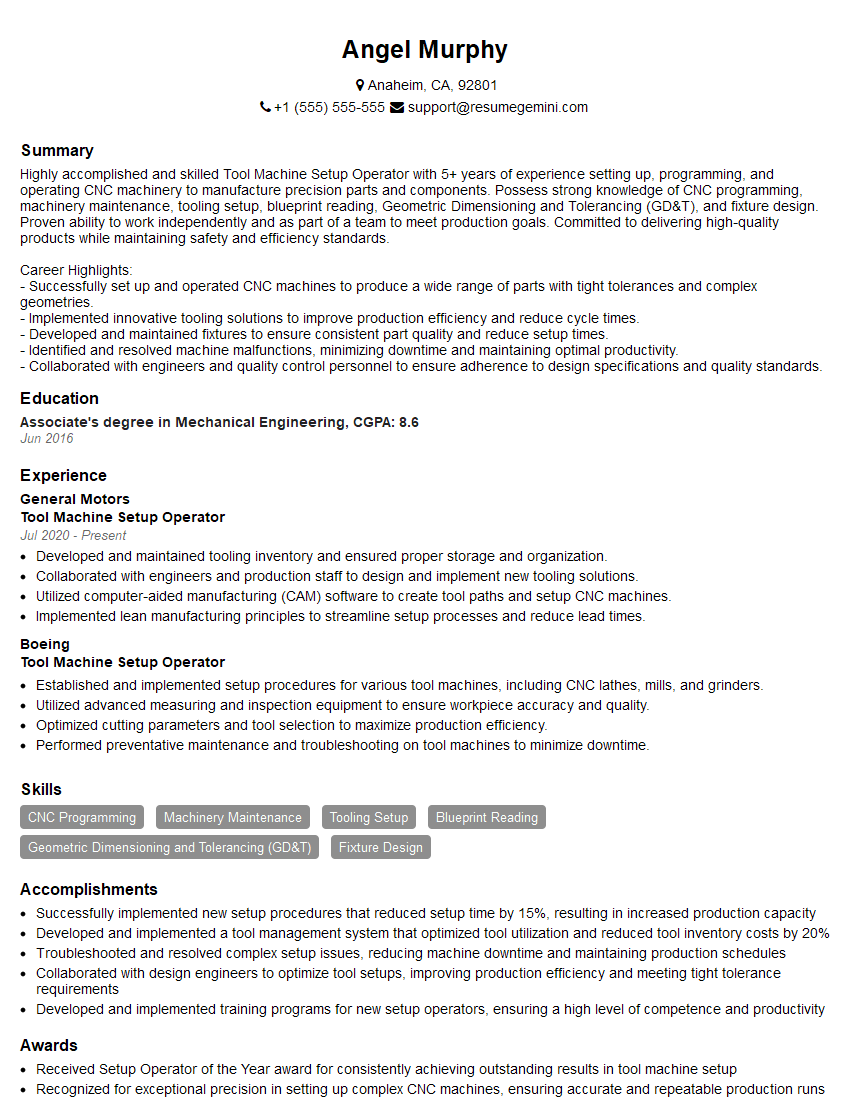

Angel Murphy

Tool Machine Setup Operator

Summary

Highly accomplished and skilled Tool Machine Setup Operator with 5+ years of experience setting up, programming, and operating CNC machinery to manufacture precision parts and components. Possess strong knowledge of CNC programming, machinery maintenance, tooling setup, blueprint reading, Geometric Dimensioning and Tolerancing (GD&T), and fixture design. Proven ability to work independently and as part of a team to meet production goals. Committed to delivering high-quality products while maintaining safety and efficiency standards.

Career Highlights:

– Successfully set up and operated CNC machines to produce a wide range of parts with tight tolerances and complex geometries.

– Implemented innovative tooling solutions to improve production efficiency and reduce cycle times.

– Developed and maintained fixtures to ensure consistent part quality and reduce setup times.

– Identified and resolved machine malfunctions, minimizing downtime and maintaining optimal productivity.

– Collaborated with engineers and quality control personnel to ensure adherence to design specifications and quality standards.

Education

Associate’s degree in Mechanical Engineering

June 2016

Skills

- CNC Programming

- Machinery Maintenance

- Tooling Setup

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Fixture Design

Work Experience

Tool Machine Setup Operator

- Developed and maintained tooling inventory and ensured proper storage and organization.

- Collaborated with engineers and production staff to design and implement new tooling solutions.

- Utilized computer-aided manufacturing (CAM) software to create tool paths and setup CNC machines.

- Implemented lean manufacturing principles to streamline setup processes and reduce lead times.

Tool Machine Setup Operator

- Established and implemented setup procedures for various tool machines, including CNC lathes, mills, and grinders.

- Utilized advanced measuring and inspection equipment to ensure workpiece accuracy and quality.

- Optimized cutting parameters and tool selection to maximize production efficiency.

- Performed preventative maintenance and troubleshooting on tool machines to minimize downtime.

Accomplishments

- Successfully implemented new setup procedures that reduced setup time by 15%, resulting in increased production capacity

- Developed and implemented a tool management system that optimized tool utilization and reduced tool inventory costs by 20%

- Troubleshooted and resolved complex setup issues, reducing machine downtime and maintaining production schedules

- Collaborated with design engineers to optimize tool setups, improving production efficiency and meeting tight tolerance requirements

- Developed and implemented training programs for new setup operators, ensuring a high level of competence and productivity

Awards

- Received Setup Operator of the Year award for consistently achieving outstanding results in tool machine setup

- Recognized for exceptional precision in setting up complex CNC machines, ensuring accurate and repeatable production runs

- Received Safety Excellence Award for maintaining an exemplary safety record and implementing innovative safety measures in the workplace

- Recognized for proficiency in programming and operating CNC machines, ensuring precision and accuracy in tool setup

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Tool and Die Maker Journeyman

- Certified Tooling Technician (CTT)

- Robotics Institute of America (RIA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Machine Setup Operator

- Highlight your hands-on experience with CNC machines and the specific software programs you are proficient in.

- Showcase your problem-solving and troubleshooting skills and how you have used them to improve production processes.

- Quantify your accomplishments with specific metrics, such as increased productivity, reduced setup times, or improved part quality.

- Include any certifications or training you have completed, such as CNC programming or GD&T certification.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Tool Machine Setup Operator Resume

- Set up and operate CNC machines (e.g., mills, lathes, grinders) according to blueprints and specifications.

- Program and debug CNC machine controllers using G-code or other programming languages.

- Select and install appropriate tooling, fixtures, and cutting parameters to achieve desired results.

- Inspect and measure parts to ensure they meet specifications and quality standards.

- Perform preventive maintenance and troubleshoot machine problems to minimize downtime.

- Maintain a clean and organized work area to promote safety and efficiency.

- Follow safety protocols and comply with all applicable regulations.

Frequently Asked Questions (FAQ’s) For Tool Machine Setup Operator

What are the key skills required to be a successful Tool Machine Setup Operator?

The key skills required to be a successful Tool Machine Setup Operator include CNC programming, machinery maintenance, tooling setup, blueprint reading, Geometric Dimensioning and Tolerancing (GD&T), and fixture design.

What are the career prospects for Tool Machine Setup Operators?

Tool Machine Setup Operators are in high demand due to the increasing use of CNC machines in various industries. With experience and additional skills, they can advance to positions such as CNC programmer, manufacturing engineer, or quality control inspector.

How can I improve my chances of getting hired as a Tool Machine Setup Operator?

To improve your chances of getting hired as a Tool Machine Setup Operator, consider completing an associate’s degree in mechanical engineering or a related field, obtaining CNC programming and GD&T certifications, and gaining hands-on experience through internships or apprenticeships.

What are the typical working conditions for Tool Machine Setup Operators?

Tool Machine Setup Operators typically work in manufacturing facilities, operating CNC machines in a controlled environment. They may need to stand for long periods, lift heavy objects, and work with sharp tools and machinery.

What is the average salary for Tool Machine Setup Operators?

The average salary for Tool Machine Setup Operators varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for CNC machine operators was $49,950 in May 2021.

What are the major challenges faced by Tool Machine Setup Operators?

The major challenges faced by Tool Machine Setup Operators include working with complex machinery, ensuring precision and accuracy in their work, meeting tight production deadlines, and staying updated with the latest technological advancements.

What are the growth opportunities for Tool Machine Setup Operators?

Tool Machine Setup Operators can advance their careers by gaining experience and developing additional skills. They may move into supervisory roles, become CNC programmers, or specialize in specific areas such as tooling design or quality control.