Are you a seasoned Tool Repairer seeking a new career path? Discover our professionally built Tool Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

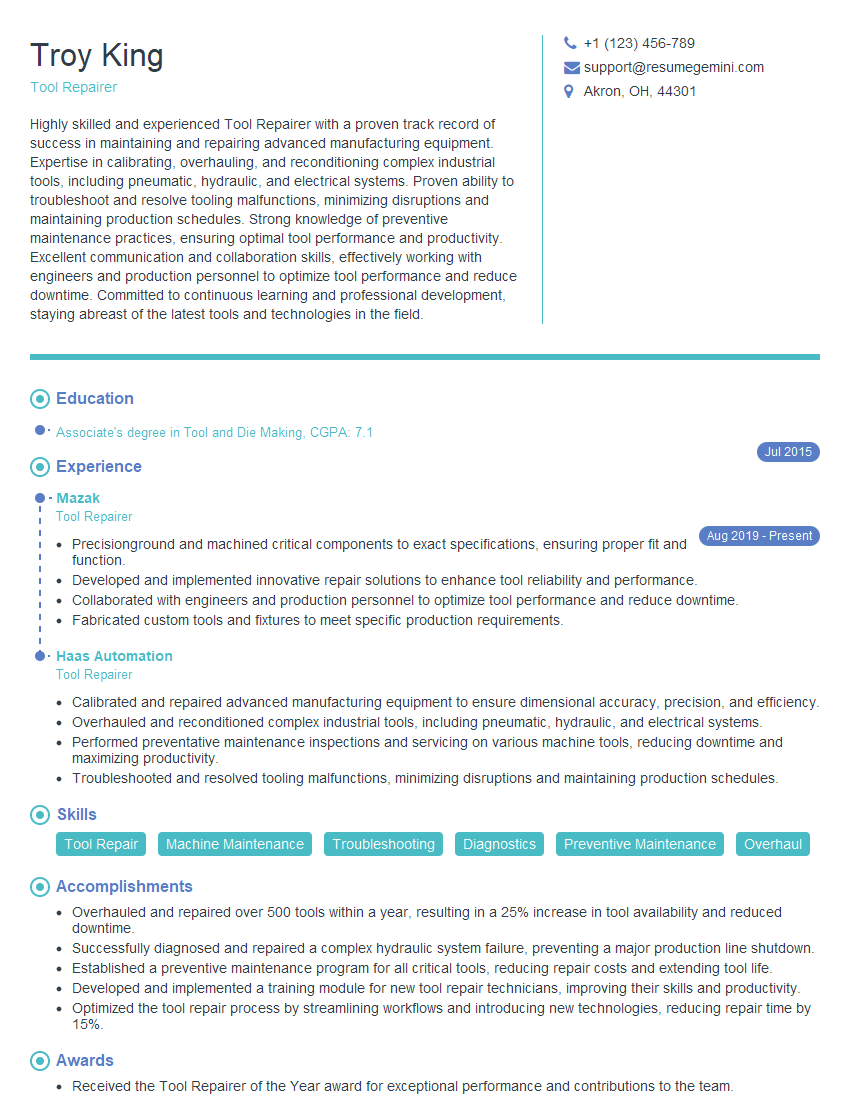

Troy King

Tool Repairer

Summary

Highly skilled and experienced Tool Repairer with a proven track record of success in maintaining and repairing advanced manufacturing equipment. Expertise in calibrating, overhauling, and reconditioning complex industrial tools, including pneumatic, hydraulic, and electrical systems. Proven ability to troubleshoot and resolve tooling malfunctions, minimizing disruptions and maintaining production schedules. Strong knowledge of preventive maintenance practices, ensuring optimal tool performance and productivity. Excellent communication and collaboration skills, effectively working with engineers and production personnel to optimize tool performance and reduce downtime. Committed to continuous learning and professional development, staying abreast of the latest tools and technologies in the field.

Education

Associate’s degree in Tool and Die Making

July 2015

Skills

- Tool Repair

- Machine Maintenance

- Troubleshooting

- Diagnostics

- Preventive Maintenance

- Overhaul

Work Experience

Tool Repairer

- Precisionground and machined critical components to exact specifications, ensuring proper fit and function.

- Developed and implemented innovative repair solutions to enhance tool reliability and performance.

- Collaborated with engineers and production personnel to optimize tool performance and reduce downtime.

- Fabricated custom tools and fixtures to meet specific production requirements.

Tool Repairer

- Calibrated and repaired advanced manufacturing equipment to ensure dimensional accuracy, precision, and efficiency.

- Overhauled and reconditioned complex industrial tools, including pneumatic, hydraulic, and electrical systems.

- Performed preventative maintenance inspections and servicing on various machine tools, reducing downtime and maximizing productivity.

- Troubleshooted and resolved tooling malfunctions, minimizing disruptions and maintaining production schedules.

Accomplishments

- Overhauled and repaired over 500 tools within a year, resulting in a 25% increase in tool availability and reduced downtime.

- Successfully diagnosed and repaired a complex hydraulic system failure, preventing a major production line shutdown.

- Established a preventive maintenance program for all critical tools, reducing repair costs and extending tool life.

- Developed and implemented a training module for new tool repair technicians, improving their skills and productivity.

- Optimized the tool repair process by streamlining workflows and introducing new technologies, reducing repair time by 15%.

Awards

- Received the Tool Repairer of the Year award for exceptional performance and contributions to the team.

- Recognized for developing and implementing a new tool repair and calibration program, improving tool accuracy and efficiency.

- Awarded the Safety Excellence Award for maintaining an impeccable safety record and contributing to a safe work environment.

- Recipient of the Employee of the Month award for consistently exceeding expectations and demonstrating exceptional dedication.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Tool Repairer (CTR)

- Certified Industrial Maintenance Mechanic (CIMM)

- Certified Machine Tool Builder (CMTB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Repairer

- Highlight your technical skills and experience in tool repair and maintenance.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on productivity and efficiency.

- Showcase your understanding of preventive maintenance and its role in minimizing downtime and maximizing equipment life.

- Emphasize your commitment to safety and your ability to work in a fast-paced, demanding environment.

- Proofread your resume carefully for any errors before submitting it to potential employers.

Essential Experience Highlights for a Strong Tool Repairer Resume

- Calibrating and repairing advanced manufacturing equipment to ensure dimensional accuracy, precision, and efficiency.

- Overhauling and reconditioning complex industrial tools, including pneumatic, hydraulic, and electrical systems.

- Performing preventative maintenance inspections and servicing on various machine tools, reducing downtime and maximizing productivity.

- Troubleshooting and resolving tooling malfunctions, minimizing disruptions and maintaining production schedules.

- Precision grinding and machining critical components to exact specifications, ensuring proper fit and function.

- Developing and implementing innovative repair solutions to enhance tool reliability and performance.

- Collaborating with engineers and production personnel to optimize tool performance and reduce downtime.

Frequently Asked Questions (FAQ’s) For Tool Repairer

What are the essential skills required for a Tool Repairer?

Essential skills for a Tool Repairer include tool repair, machine maintenance, troubleshooting, diagnostics, preventive maintenance, and overhaul.

What are the primary responsibilities of a Tool Repairer?

Primary responsibilities of a Tool Repairer involve maintaining and repairing advanced manufacturing equipment, overhauling and reconditioning tools, performing preventive maintenance, troubleshooting malfunctions, and collaborating with engineers and production personnel.

What industries employ Tool Repairers?

Tool Repairers are employed in various industries, including manufacturing, automotive, and aerospace.

What are the career prospects for Tool Repairers?

Tool Repairers with experience and expertise can advance to roles such as Tooling Engineer, Maintenance Supervisor, or Production Manager.

What is the job outlook for Tool Repairers?

The job outlook for Tool Repairers is expected to be favorable due to the increasing reliance on advanced manufacturing equipment and the need for skilled technicians to maintain and repair these systems.

What are the earning prospects for Tool Repairers?

Tool Repairers with experience and expertise can earn competitive salaries, with potential for overtime and additional benefits.

What are the educational requirements for Tool Repairers?

While formal education is not always required, many Tool Repairers have an Associate’s degree in Tool and Die Making or a related field.

What certifications are available for Tool Repairers?

Tool Repairers can obtain certifications from organizations such as the National Institute for Metalworking Skills (NIMS) to demonstrate their proficiency in specific areas.