Are you a seasoned Tool Room Attendant seeking a new career path? Discover our professionally built Tool Room Attendant Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

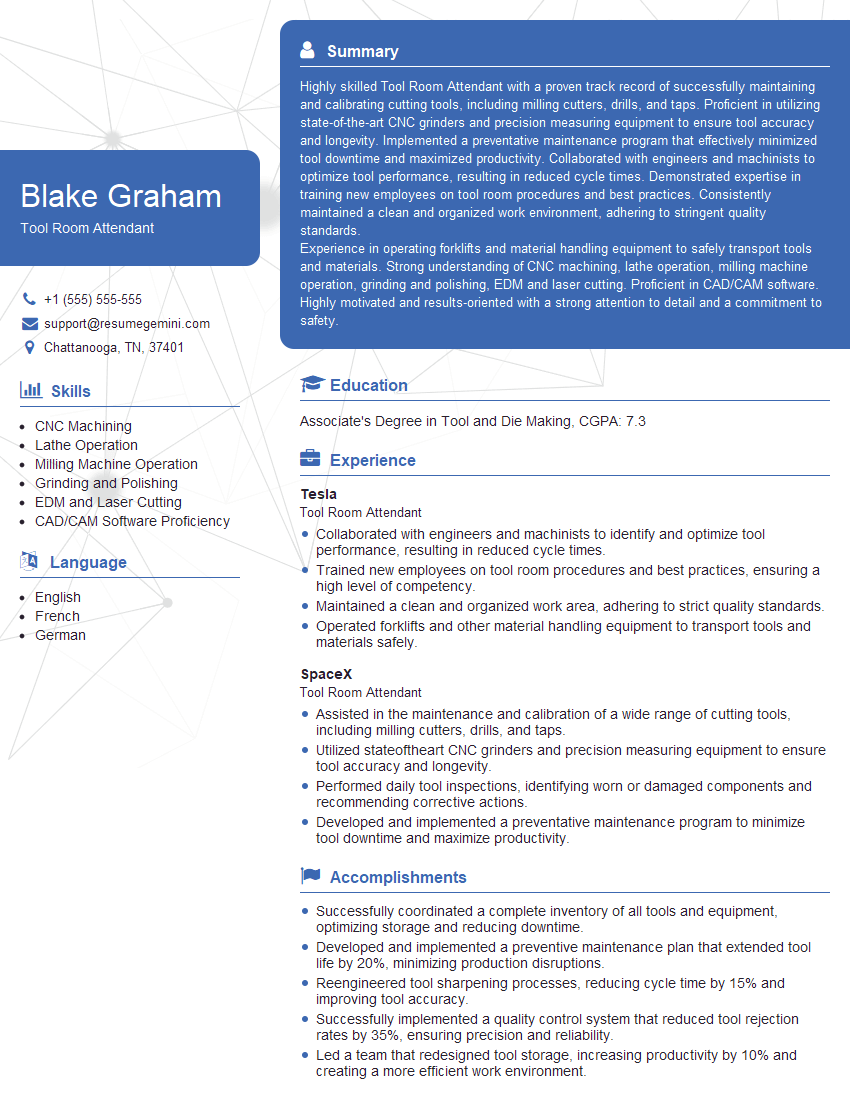

Blake Graham

Tool Room Attendant

Summary

Highly skilled Tool Room Attendant with a proven track record of successfully maintaining and calibrating cutting tools, including milling cutters, drills, and taps. Proficient in utilizing state-of-the-art CNC grinders and precision measuring equipment to ensure tool accuracy and longevity. Implemented a preventative maintenance program that effectively minimized tool downtime and maximized productivity. Collaborated with engineers and machinists to optimize tool performance, resulting in reduced cycle times. Demonstrated expertise in training new employees on tool room procedures and best practices. Consistently maintained a clean and organized work environment, adhering to stringent quality standards.

Experience in operating forklifts and material handling equipment to safely transport tools and materials. Strong understanding of CNC machining, lathe operation, milling machine operation, grinding and polishing, EDM and laser cutting. Proficient in CAD/CAM software. Highly motivated and results-oriented with a strong attention to detail and a commitment to safety.

Education

Associate’s Degree in Tool and Die Making

March 2019

Skills

- CNC Machining

- Lathe Operation

- Milling Machine Operation

- Grinding and Polishing

- EDM and Laser Cutting

- CAD/CAM Software Proficiency

Work Experience

Tool Room Attendant

- Collaborated with engineers and machinists to identify and optimize tool performance, resulting in reduced cycle times.

- Trained new employees on tool room procedures and best practices, ensuring a high level of competency.

- Maintained a clean and organized work area, adhering to strict quality standards.

- Operated forklifts and other material handling equipment to transport tools and materials safely.

Tool Room Attendant

- Assisted in the maintenance and calibration of a wide range of cutting tools, including milling cutters, drills, and taps.

- Utilized stateoftheart CNC grinders and precision measuring equipment to ensure tool accuracy and longevity.

- Performed daily tool inspections, identifying worn or damaged components and recommending corrective actions.

- Developed and implemented a preventative maintenance program to minimize tool downtime and maximize productivity.

Accomplishments

- Successfully coordinated a complete inventory of all tools and equipment, optimizing storage and reducing downtime.

- Developed and implemented a preventive maintenance plan that extended tool life by 20%, minimizing production disruptions.

- Reengineered tool sharpening processes, reducing cycle time by 15% and improving tool accuracy.

- Successfully implemented a quality control system that reduced tool rejection rates by 35%, ensuring precision and reliability.

- Led a team that redesigned tool storage, increasing productivity by 10% and creating a more efficient work environment.

Awards

- Received Tool Room Attendant of the Year award for exceptional performance and contributions to the team.

- Recognized with Excellence in Tooling Award for innovative solutions and improvements to tool maintenance practices.

- Nominated for Best Tool Room Attendant Award for outstanding knowledge of machinery and ability to troubleshoot complex issues.

- Awarded Safety Excellence Award for maintaining an exemplary safety record and promoting a positive safety culture in the tool room.

Certificates

- CNC Operator Certification

- Lathe Operator Certification

- Milling Machine Operator Certification

- EDM Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Room Attendant

- Highlight your experience in maintaining and calibrating cutting tools, as well as your proficiency in using state-of-the-art CNC grinders and precision measuring equipment.

- Quantify your accomplishments whenever possible. For example, you could mention the specific percentage by which you reduced tool downtime or increased productivity.

- Showcase your teamwork and communication skills by highlighting your experience collaborating with engineers and machinists.

- Demonstrate your commitment to safety by mentioning your adherence to strict quality standards and your experience operating forklifts and other material handling equipment safely.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Tool Room Attendant Resume

- Maintain and calibrate a wide range of cutting tools, including milling cutters, drills, and taps.

- Utilize state-of-the-art CNC grinders and precision measuring equipment to ensure tool accuracy and longevity.

- Inspect tools daily, identify worn or damaged components, and recommend corrective actions.

- Develop and implement preventative maintenance programs to minimize tool downtime and maximize productivity.

- Collaborate with engineers and machinists to identify and optimize tool performance, resulting in reduced cycle times.

- Train new employees on tool room procedures and best practices, ensuring a high level of competency.

- Maintain a clean and organized work area, adhering to strict quality standards.

- Operate forklifts and other material handling equipment to transport tools and materials safely.

Frequently Asked Questions (FAQ’s) For Tool Room Attendant

What are the primary responsibilities of a Tool Room Attendant?

The primary responsibilities of a Tool Room Attendant include maintaining and calibrating cutting tools, inspecting tools for wear and damage, developing and implementing preventative maintenance programs, training new employees, and maintaining a clean and organized work area.

What skills are required to be successful as a Tool Room Attendant?

To be successful as a Tool Room Attendant, you will need to have strong mechanical skills, as well as experience in operating and maintaining CNC grinders and other precision measuring equipment. You should also be able to read and interpret blueprints and have a good understanding of toolmaking principles.

What is the typical work environment for a Tool Room Attendant?

Tool Room Attendants typically work in a manufacturing or industrial setting. They may be required to work in a variety of conditions, including exposure to noise, dust, and chemicals.

What is the average salary for a Tool Room Attendant?

The average salary for a Tool Room Attendant in the United States is around $45,000 per year.

What are the career advancement opportunities for a Tool Room Attendant?

With experience, Tool Room Attendants may be able to advance to positions such as Tool and Die Maker, CNC Programmer, or Quality Control Inspector.

What are the educational requirements for a Tool Room Attendant?

While there are no formal educational requirements for a Tool Room Attendant, most employers prefer candidates with an Associate’s Degree in Tool and Die Making or a related field.

What are the certification requirements for a Tool Room Attendant?

There are no certification requirements for a Tool Room Attendant, but some employers may prefer candidates who have obtained certifications from organizations such as the National Tooling and Machining Association (NTMA).