Are you a seasoned Tool Room Machinist seeking a new career path? Discover our professionally built Tool Room Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

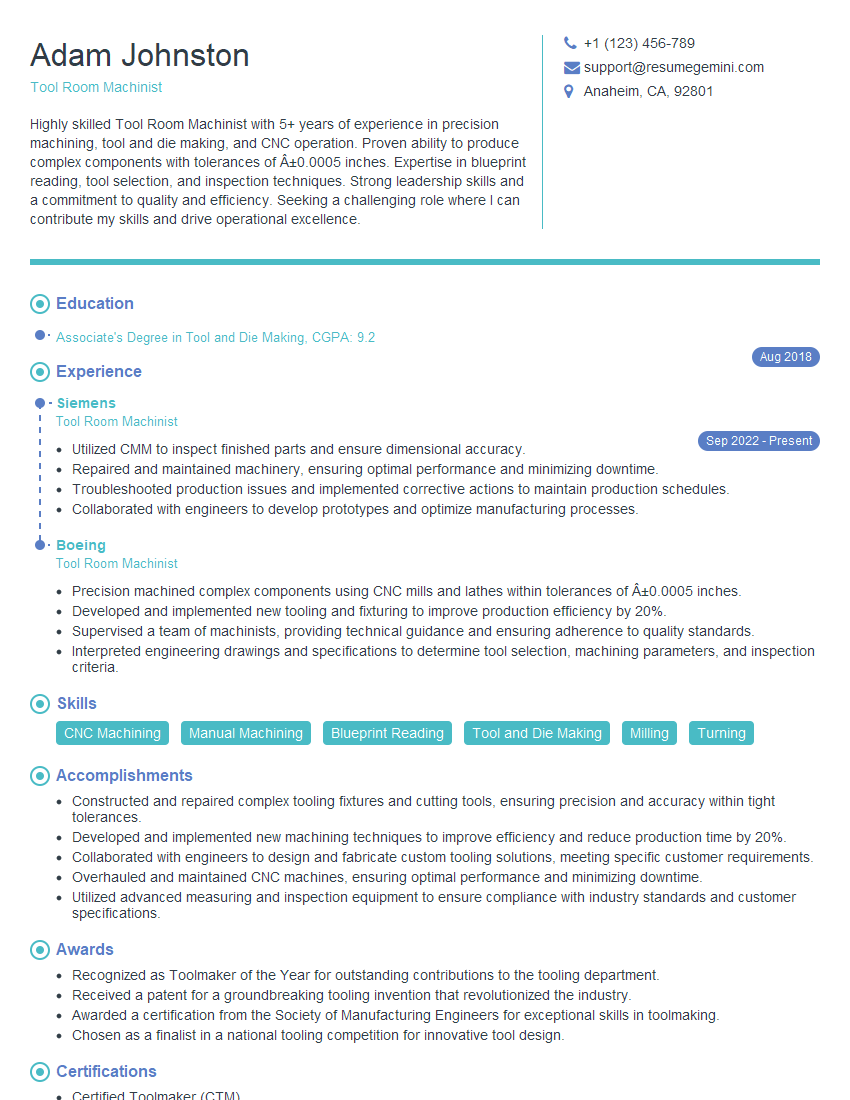

Adam Johnston

Tool Room Machinist

Summary

Highly skilled Tool Room Machinist with 5+ years of experience in precision machining, tool and die making, and CNC operation. Proven ability to produce complex components with tolerances of ±0.0005 inches. Expertise in blueprint reading, tool selection, and inspection techniques. Strong leadership skills and a commitment to quality and efficiency. Seeking a challenging role where I can contribute my skills and drive operational excellence.

Education

Associate’s Degree in Tool and Die Making

August 2018

Skills

- CNC Machining

- Manual Machining

- Blueprint Reading

- Tool and Die Making

- Milling

- Turning

Work Experience

Tool Room Machinist

- Utilized CMM to inspect finished parts and ensure dimensional accuracy.

- Repaired and maintained machinery, ensuring optimal performance and minimizing downtime.

- Troubleshooted production issues and implemented corrective actions to maintain production schedules.

- Collaborated with engineers to develop prototypes and optimize manufacturing processes.

Tool Room Machinist

- Precision machined complex components using CNC mills and lathes within tolerances of ±0.0005 inches.

- Developed and implemented new tooling and fixturing to improve production efficiency by 20%.

- Supervised a team of machinists, providing technical guidance and ensuring adherence to quality standards.

- Interpreted engineering drawings and specifications to determine tool selection, machining parameters, and inspection criteria.

Accomplishments

- Constructed and repaired complex tooling fixtures and cutting tools, ensuring precision and accuracy within tight tolerances.

- Developed and implemented new machining techniques to improve efficiency and reduce production time by 20%.

- Collaborated with engineers to design and fabricate custom tooling solutions, meeting specific customer requirements.

- Overhauled and maintained CNC machines, ensuring optimal performance and minimizing downtime.

- Utilized advanced measuring and inspection equipment to ensure compliance with industry standards and customer specifications.

Awards

- Recognized as Toolmaker of the Year for outstanding contributions to the tooling department.

- Received a patent for a groundbreaking tooling invention that revolutionized the industry.

- Awarded a certification from the Society of Manufacturing Engineers for exceptional skills in toolmaking.

- Chosen as a finalist in a national tooling competition for innovative tool design.

Certificates

- Certified Toolmaker (CTM)

- Certified Machinist (CM)

- ISO 9001:2015

- AS9100

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Room Machinist

Highlight your precision machining skills:

Quantify your experience and results with specific examples of complex components you’ve machined and the tolerances you’ve achieved.Showcase your knowledge of CNC operation:

Describe your expertise in using CNC mills and lathes, including your proficiency in programming and setup.Emphasize your tool and die making skills:

Explain your experience in designing, fabricating, and maintaining tools and dies, including your knowledge of materials, heat treatment, and grinding techniques.Demonstrate your quality assurance experience:

Describe your role in implementing and maintaining quality control procedures, including inspection techniques and corrective actions.

Essential Experience Highlights for a Strong Tool Room Machinist Resume

- Machined complex components using CNC mills and lathes to tolerances of ±0.0005 inches.

- Developed and implemented new tooling and fixturing to improve production efficiency by 20%.

- Supervised a team of machinists, providing technical guidance and ensuring adherence to quality standards.

- Interpreted engineering drawings and specifications to determine tool selection, machining parameters, and inspection criteria.

Frequently Asked Questions (FAQ’s) For Tool Room Machinist

What is the role of a Tool Room Machinist?

A Tool Room Machinist is responsible for producing precision components using CNC mills, lathes, and other machining equipment. They work closely with engineers to design and fabricate tools, dies, and fixtures, and they ensure that all components meet the required specifications.

What skills are required to be a successful Tool Room Machinist?

Successful Tool Room Machinists have a strong understanding of machining principles, CNC programming, and quality control. They are also proficient in blueprint reading, tool selection, and inspection techniques.

What is the career path for a Tool Room Machinist?

Tool Room Machinists can advance to positions such as Supervisor, Quality Control Inspector, or Manufacturing Engineer. With additional education and experience, they can also move into management roles.

What are the benefits of being a Tool Room Machinist?

Tool Room Machinists enjoy a stable career with good earning potential. They also have the opportunity to work with cutting-edge technology and contribute to the manufacturing process.

How can I become a Tool Room Machinist?

To become a Tool Room Machinist, you typically need a high school diploma or equivalent, as well as an Associate’s Degree in Tool and Die Making or a related field.

What is the job outlook for Tool Room Machinists?

The job outlook for Tool Room Machinists is expected to be good over the next few years. As the manufacturing industry continues to grow, the demand for skilled machinists will increase.

What are the challenges of being a Tool Room Machinist?

Tool Room Machinists face a number of challenges, including the need for precision and accuracy, the need to work with potentially hazardous materials, and the need to meet tight deadlines.

What are the rewards of being a Tool Room Machinist?

Tool Room Machinists enjoy a number of rewards, including the satisfaction of creating high-quality products, the opportunity to work with cutting-edge technology, and the potential for career advancement.