Are you a seasoned Toolroom Attendant seeking a new career path? Discover our professionally built Toolroom Attendant Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

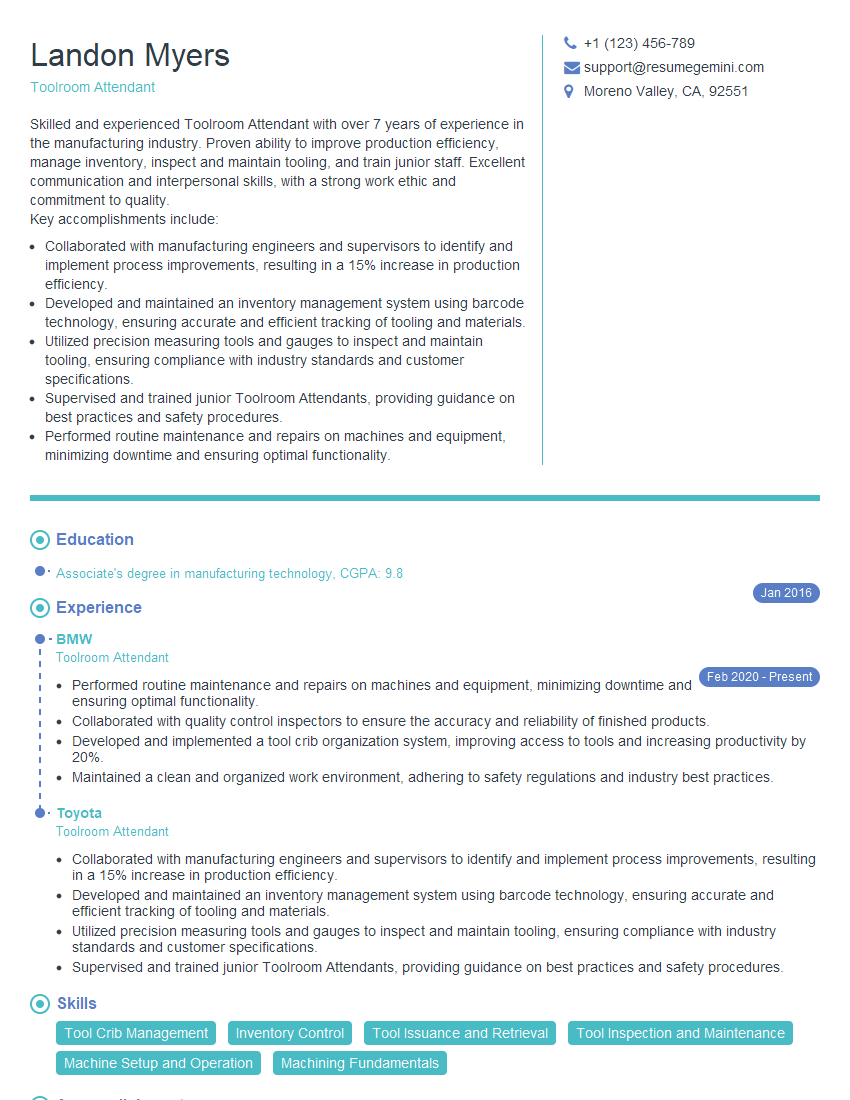

Landon Myers

Toolroom Attendant

Summary

Skilled and experienced Toolroom Attendant with over 7 years of experience in the manufacturing industry. Proven ability to improve production efficiency, manage inventory, inspect and maintain tooling, and train junior staff. Excellent communication and interpersonal skills, with a strong work ethic and commitment to quality.

Key accomplishments include:

- Collaborated with manufacturing engineers and supervisors to identify and implement process improvements, resulting in a 15% increase in production efficiency.

- Developed and maintained an inventory management system using barcode technology, ensuring accurate and efficient tracking of tooling and materials.

- Utilized precision measuring tools and gauges to inspect and maintain tooling, ensuring compliance with industry standards and customer specifications.

- Supervised and trained junior Toolroom Attendants, providing guidance on best practices and safety procedures.

- Performed routine maintenance and repairs on machines and equipment, minimizing downtime and ensuring optimal functionality.

Education

Associate’s degree in manufacturing technology

January 2016

Skills

- Tool Crib Management

- Inventory Control

- Tool Issuance and Retrieval

- Tool Inspection and Maintenance

- Machine Setup and Operation

- Machining Fundamentals

Work Experience

Toolroom Attendant

- Performed routine maintenance and repairs on machines and equipment, minimizing downtime and ensuring optimal functionality.

- Collaborated with quality control inspectors to ensure the accuracy and reliability of finished products.

- Developed and implemented a tool crib organization system, improving access to tools and increasing productivity by 20%.

- Maintained a clean and organized work environment, adhering to safety regulations and industry best practices.

Toolroom Attendant

- Collaborated with manufacturing engineers and supervisors to identify and implement process improvements, resulting in a 15% increase in production efficiency.

- Developed and maintained an inventory management system using barcode technology, ensuring accurate and efficient tracking of tooling and materials.

- Utilized precision measuring tools and gauges to inspect and maintain tooling, ensuring compliance with industry standards and customer specifications.

- Supervised and trained junior Toolroom Attendants, providing guidance on best practices and safety procedures.

Accomplishments

- Developed a new jig that reduced setup time for a key component by 20%.

- Implemented a preventive maintenance program that extended the lifespan of critical tooling by 30%.

- Trained new toolroom technicians on industry best practices, resulting in a 10% improvement in productivity.

- Implemented a system for tracking tool usage that reduced inventory levels by 15%.

- Identified and resolved a tooling issue that was causing production delays, saving the company significant downtime.

Awards

- Toolroom Excellence Award for exceeding production targets by 15%.

- Safety Award for maintaining a spotless safety record in the toolroom.

- Employee of the Month for consistently exceeding performance expectations.

- Toolroom Innovation Award for developing a new tool that improved production efficiency by 12%.

Certificates

- Certified Toolroom Attendant (CTA)

- OSHA General Industry Safety (10-Hour)

- ISO 9001:2015 Quality Management

- Six Sigma Yellow Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Toolroom Attendant

- Highlight your experience in tool crib management and inventory control, as these are key responsibilities of a Toolroom Attendant.

- Showcase your technical skills, such as machine setup and operation, and your knowledge of machining fundamentals.

- Emphasize your ability to work independently and as part of a team, as collaboration is essential in a manufacturing environment.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

Essential Experience Highlights for a Strong Toolroom Attendant Resume

- Manage and maintain the tool crib, ensuring the availability and proper storage of tools and materials.

- Issue and retrieve tools and equipment to authorized personnel, maintaining accurate records of transactions.

- Inspect and maintain tools and equipment, ensuring compliance with safety regulations and industry standards.

- Set up and operate machines and equipment, following established procedures and specifications.

- Collaborate with engineers and other departments to identify and implement process improvements.

- Train and supervise junior Toolroom Attendants, providing guidance and support.

- Maintain a clean and organized work environment, adhering to safety protocols.

Frequently Asked Questions (FAQ’s) For Toolroom Attendant

What are the key responsibilities of a Toolroom Attendant?

The key responsibilities of a Toolroom Attendant typically include managing the tool crib, issuing and retrieving tools and equipment, inspecting and maintaining tools, setting up and operating machines, collaborating with other departments, and maintaining a clean and organized work environment.

What are the educational requirements to become a Toolroom Attendant?

While formal education requirements may vary depending on the specific job and company, many Toolroom Attendants hold an associate’s degree in manufacturing technology or a related field.

What are the essential skills for a Toolroom Attendant?

Essential skills for a Toolroom Attendant include tool crib management, inventory control, tool issuance and retrieval, tool inspection and maintenance, machine setup and operation, and machining fundamentals.

What is the work environment like for a Toolroom Attendant?

Toolroom Attendants typically work in a manufacturing environment, which can involve working with machinery, tools, and materials. They may also work with other employees, such as engineers, supervisors, and machinists.

What is the career path for a Toolroom Attendant?

With experience and additional training, Toolroom Attendants can advance to roles such as Toolroom Supervisor, Manufacturing Engineer, or Production Manager.

What are the benefits of being a Toolroom Attendant?

Benefits of being a Toolroom Attendant may include competitive pay, job stability, opportunities for advancement, and a sense of accomplishment from contributing to the manufacturing process.

What are the challenges of being a Toolroom Attendant?

Challenges of being a Toolroom Attendant may include working in a fast-paced and demanding environment, exposure to noise and potential hazards, and the need for physical strength and stamina.

How can I prepare for a career as a Toolroom Attendant?

To prepare for a career as a Toolroom Attendant, you can consider obtaining an associate’s degree in manufacturing technology or a related field, developing skills in tool crib management and inventory control, and gaining experience working with machinery and tools.