Are you a seasoned Toolroom Checker seeking a new career path? Discover our professionally built Toolroom Checker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

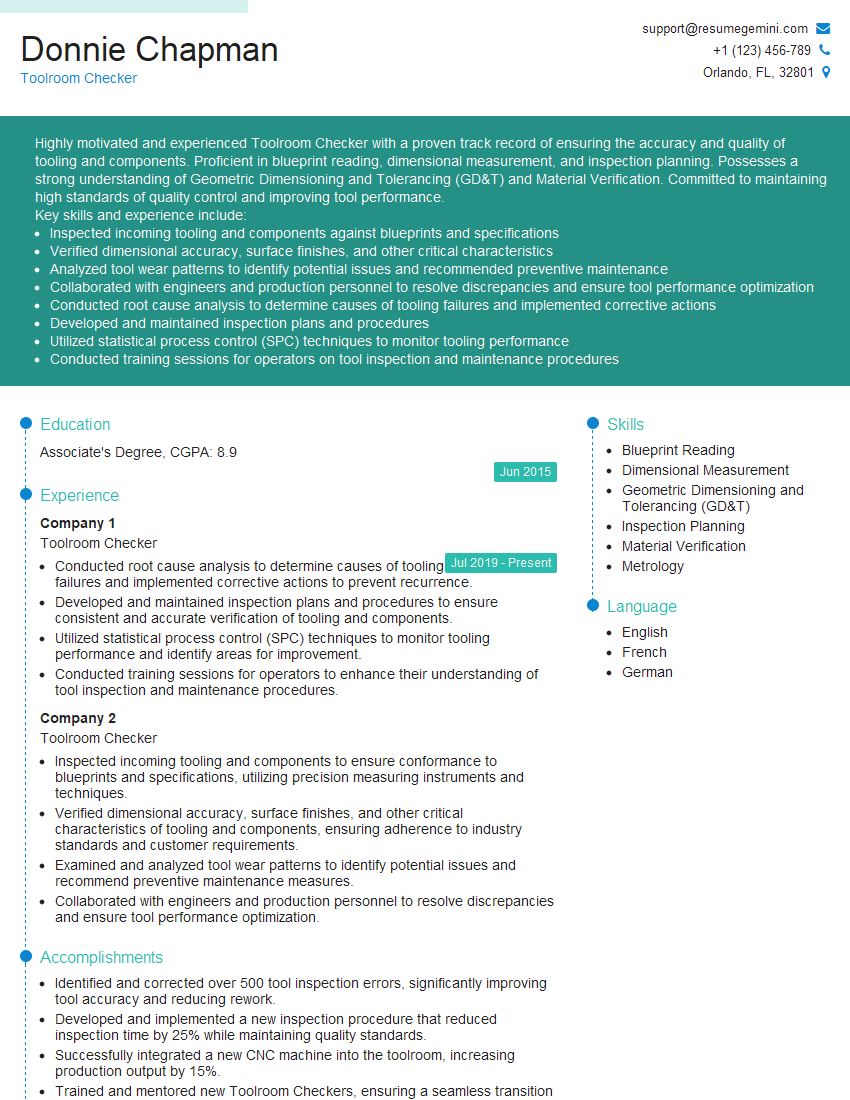

Donnie Chapman

Toolroom Checker

Summary

Highly motivated and experienced Toolroom Checker with a proven track record of ensuring the accuracy and quality of tooling and components. Proficient in blueprint reading, dimensional measurement, and inspection planning. Possesses a strong understanding of Geometric Dimensioning and Tolerancing (GD&T) and Material Verification. Committed to maintaining high standards of quality control and improving tool performance.

Key skills and experience include:

- Inspected incoming tooling and components against blueprints and specifications

- Verified dimensional accuracy, surface finishes, and other critical characteristics

- Analyzed tool wear patterns to identify potential issues and recommended preventive maintenance

- Collaborated with engineers and production personnel to resolve discrepancies and ensure tool performance optimization

- Conducted root cause analysis to determine causes of tooling failures and implemented corrective actions

- Developed and maintained inspection plans and procedures

- Utilized statistical process control (SPC) techniques to monitor tooling performance

- Conducted training sessions for operators on tool inspection and maintenance procedures

Education

Associate’s Degree

June 2015

Skills

- Blueprint Reading

- Dimensional Measurement

- Geometric Dimensioning and Tolerancing (GD&T)

- Inspection Planning

- Material Verification

- Metrology

Work Experience

Toolroom Checker

- Conducted root cause analysis to determine causes of tooling failures and implemented corrective actions to prevent recurrence.

- Developed and maintained inspection plans and procedures to ensure consistent and accurate verification of tooling and components.

- Utilized statistical process control (SPC) techniques to monitor tooling performance and identify areas for improvement.

- Conducted training sessions for operators to enhance their understanding of tool inspection and maintenance procedures.

Toolroom Checker

- Inspected incoming tooling and components to ensure conformance to blueprints and specifications, utilizing precision measuring instruments and techniques.

- Verified dimensional accuracy, surface finishes, and other critical characteristics of tooling and components, ensuring adherence to industry standards and customer requirements.

- Examined and analyzed tool wear patterns to identify potential issues and recommend preventive maintenance measures.

- Collaborated with engineers and production personnel to resolve discrepancies and ensure tool performance optimization.

Accomplishments

- Identified and corrected over 500 tool inspection errors, significantly improving tool accuracy and reducing rework.

- Developed and implemented a new inspection procedure that reduced inspection time by 25% while maintaining quality standards.

- Successfully integrated a new CNC machine into the toolroom, increasing production output by 15%.

- Trained and mentored new Toolroom Checkers, ensuring a seamless transition and highquality inspections.

- Collaborated with engineers to optimize tool design, leading to improved manufacturing efficiency and reduced scrap rates.

Awards

- Received the Toolroom Checker of the Year award for exceptional performance and contributions to the team.

- Recognized for outstanding performance in implementing a new inspection system that improved quality and reduced downtime.

Certificates

- ASQ Certified Quality Inspector

- ASNT Level II Inspector

- CMM Programmer Certificate

- Coordinate Metrology Society (CMS) Certified Dimensional Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Toolroom Checker

- Highlight your proficiency in blueprint reading, dimensional measurement, and GD&T.

- Quantify your accomplishments whenever possible, such as reducing tooling failures or improving tool performance.

- Demonstrate your commitment to quality control and continuous improvement.

- Showcase your ability to work independently and as part of a team.

- Include relevant certifications or training in your resume, such as ASQ Certified Inspector.

Essential Experience Highlights for a Strong Toolroom Checker Resume

- Inspect incoming tooling and components to ensure conformance to blueprints and specifications.

- Verify dimensional accuracy, surface finishes, and other critical characteristics of tooling and components.

- Examine and analyze tool wear patterns to identify potential issues and recommend preventive maintenance measures.

- Collaborate with engineers and production personnel to resolve discrepancies and ensure tool performance optimization.

- Conduct root cause analysis to determine causes of tooling failures and implement corrective actions to prevent recurrence.

- Develop and maintain inspection plans and procedures to ensure consistent and accurate verification of tooling and components.

- Conducted training sessions for operators to enhance their understanding of tool inspection and maintenance procedures.

Frequently Asked Questions (FAQ’s) For Toolroom Checker

What is the primary role of a Toolroom Checker?

The primary role of a Toolroom Checker is to ensure the accuracy and quality of tooling and components used in manufacturing processes.

What are the key skills and qualifications required for this role?

Key skills and qualifications for a Toolroom Checker include blueprint reading, dimensional measurement, GD&T, inspection planning, material verification, and metrology.

What are the common industries that employ Toolroom Checkers?

Toolroom Checkers are commonly employed in manufacturing industries such as automotive, aerospace, and electronics.

What are the career advancement opportunities for Toolroom Checkers?

Toolroom Checkers can advance their careers by becoming Quality Inspectors, Quality Engineers, or Manufacturing Engineers.

What are the typical working conditions for Toolroom Checkers?

Toolroom Checkers typically work in a manufacturing environment, which may involve exposure to noise, dust, and chemicals.

What is the expected salary range for Toolroom Checkers?

The salary range for Toolroom Checkers can vary depending on experience, location, and industry, but typically falls between $40,000 to $70,000 per year.

What are the challenges faced by Toolroom Checkers?

Toolroom Checkers may face challenges such as tight deadlines, complex specifications, and the need to stay up-to-date with industry standards.

What is the job outlook for Toolroom Checkers?

The job outlook for Toolroom Checkers is expected to be stable in the coming years, with growth driven by the increasing demand for quality control in manufacturing.