Are you a seasoned Toolroom Machinist seeking a new career path? Discover our professionally built Toolroom Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

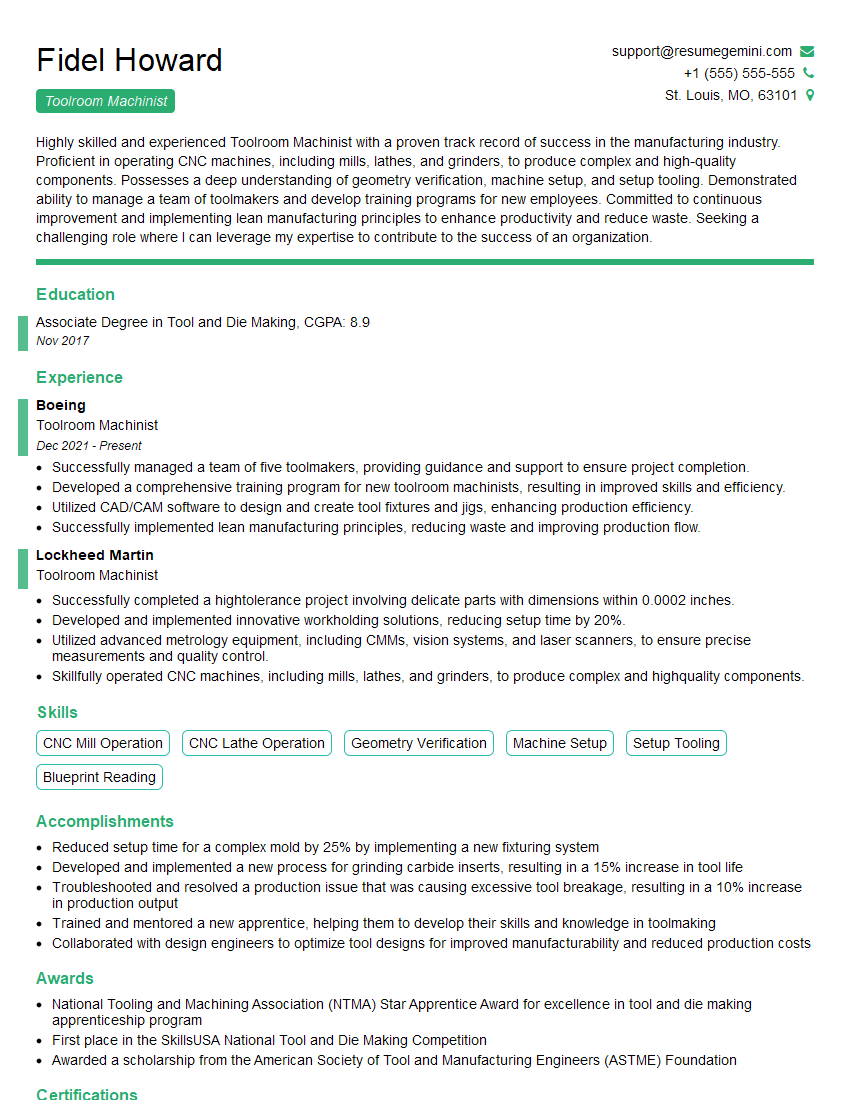

Fidel Howard

Toolroom Machinist

Summary

Highly skilled and experienced Toolroom Machinist with a proven track record of success in the manufacturing industry. Proficient in operating CNC machines, including mills, lathes, and grinders, to produce complex and high-quality components. Possesses a deep understanding of geometry verification, machine setup, and setup tooling. Demonstrated ability to manage a team of toolmakers and develop training programs for new employees. Committed to continuous improvement and implementing lean manufacturing principles to enhance productivity and reduce waste. Seeking a challenging role where I can leverage my expertise to contribute to the success of an organization.

Education

Associate Degree in Tool and Die Making

November 2017

Skills

- CNC Mill Operation

- CNC Lathe Operation

- Geometry Verification

- Machine Setup

- Setup Tooling

- Blueprint Reading

Work Experience

Toolroom Machinist

- Successfully managed a team of five toolmakers, providing guidance and support to ensure project completion.

- Developed a comprehensive training program for new toolroom machinists, resulting in improved skills and efficiency.

- Utilized CAD/CAM software to design and create tool fixtures and jigs, enhancing production efficiency.

- Successfully implemented lean manufacturing principles, reducing waste and improving production flow.

Toolroom Machinist

- Successfully completed a hightolerance project involving delicate parts with dimensions within 0.0002 inches.

- Developed and implemented innovative workholding solutions, reducing setup time by 20%.

- Utilized advanced metrology equipment, including CMMs, vision systems, and laser scanners, to ensure precise measurements and quality control.

- Skillfully operated CNC machines, including mills, lathes, and grinders, to produce complex and highquality components.

Accomplishments

- Reduced setup time for a complex mold by 25% by implementing a new fixturing system

- Developed and implemented a new process for grinding carbide inserts, resulting in a 15% increase in tool life

- Troubleshooted and resolved a production issue that was causing excessive tool breakage, resulting in a 10% increase in production output

- Trained and mentored a new apprentice, helping them to develop their skills and knowledge in toolmaking

- Collaborated with design engineers to optimize tool designs for improved manufacturability and reduced production costs

Awards

- National Tooling and Machining Association (NTMA) Star Apprentice Award for excellence in tool and die making apprenticeship program

- First place in the SkillsUSA National Tool and Die Making Competition

- Awarded a scholarship from the American Society of Tool and Manufacturing Engineers (ASTME) Foundation

Certificates

- Certified Journeyman Toolmaker, National Tooling and Machining Association (NTMA)

- CNC Programming Certificate, National Institute for Metalworking Skills (NIMS)

- Machinist Level II Certificate, Precision Machining Institute (PMI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Toolroom Machinist

- Highlight your expertise in CNC machining and geometry verification, showcasing your ability to produce high-precision components.

- Quantify your accomplishments with specific metrics, such as reducing setup time by a certain percentage or improving production efficiency by a certain amount.

- Demonstrate your leadership and management skills by describing your experience in managing a team of toolmakers and developing training programs.

- Emphasize your commitment to continuous improvement and lean manufacturing principles, highlighting your ability to enhance productivity and reduce waste.

Essential Experience Highlights for a Strong Toolroom Machinist Resume

- Operate CNC machines, including mills, lathes, and grinders, to produce complex and high-quality components.

- Read and interpret blueprints and technical drawings to ensure accurate production.

- Verify the geometry of parts using CMMs, vision systems, and laser scanners to ensure precise measurements and quality control.

- Set up and maintain machines, including tool selection, fixture design, and cutting parameter optimization.

- Troubleshoot and resolve machine and tooling issues to minimize downtime and maintain production efficiency.

- Stay updated on industry best practices and advancements in machining technology to enhance productivity.

- Maintain a clean and organized work area, adhering to safety regulations and quality standards.

Frequently Asked Questions (FAQ’s) For Toolroom Machinist

What are the primary responsibilities of a Toolroom Machinist?

Toolroom Machinists are responsible for operating CNC machines to produce complex and high-precision components, verifying the geometry of parts, setting up and maintaining machines, troubleshooting issues, and staying updated on industry best practices.

What skills are required to be a successful Toolroom Machinist?

Successful Toolroom Machinists possess strong CNC machining skills, expertise in geometry verification, the ability to read and interpret blueprints, and a deep understanding of machine setup and tooling. They are also proficient in troubleshooting and problem-solving, and are committed to continuous learning and improvement.

What industries hire Toolroom Machinists?

Toolroom Machinists are employed in a wide range of industries, including aerospace, automotive, medical, and electronics. They work in manufacturing facilities, machine shops, and tool and die shops.

What is the career outlook for Toolroom Machinists?

The career outlook for Toolroom Machinists is expected to be positive in the coming years due to the increasing demand for precision-machined components in various industries. The aging workforce and the need for skilled workers also contribute to the favorable job outlook.

What are the educational requirements to become a Toolroom Machinist?

Most Toolroom Machinists have at least an associate degree in tool and die making or a related field. They may also have completed an apprenticeship or vocational training program.

What is the average salary for a Toolroom Machinist?

The average salary for a Toolroom Machinist varies depending on experience, location, and industry. According to Indeed, the average salary for a Toolroom Machinist in the United States is around $60,000 per year.

What are the benefits of working as a Toolroom Machinist?

Toolroom Machinists enjoy a stable and rewarding career with opportunities for growth and advancement. They work in a dynamic and challenging environment, and they have the satisfaction of knowing that their work contributes to the success of various industries.