Are you a seasoned Transfer Table Operator seeking a new career path? Discover our professionally built Transfer Table Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

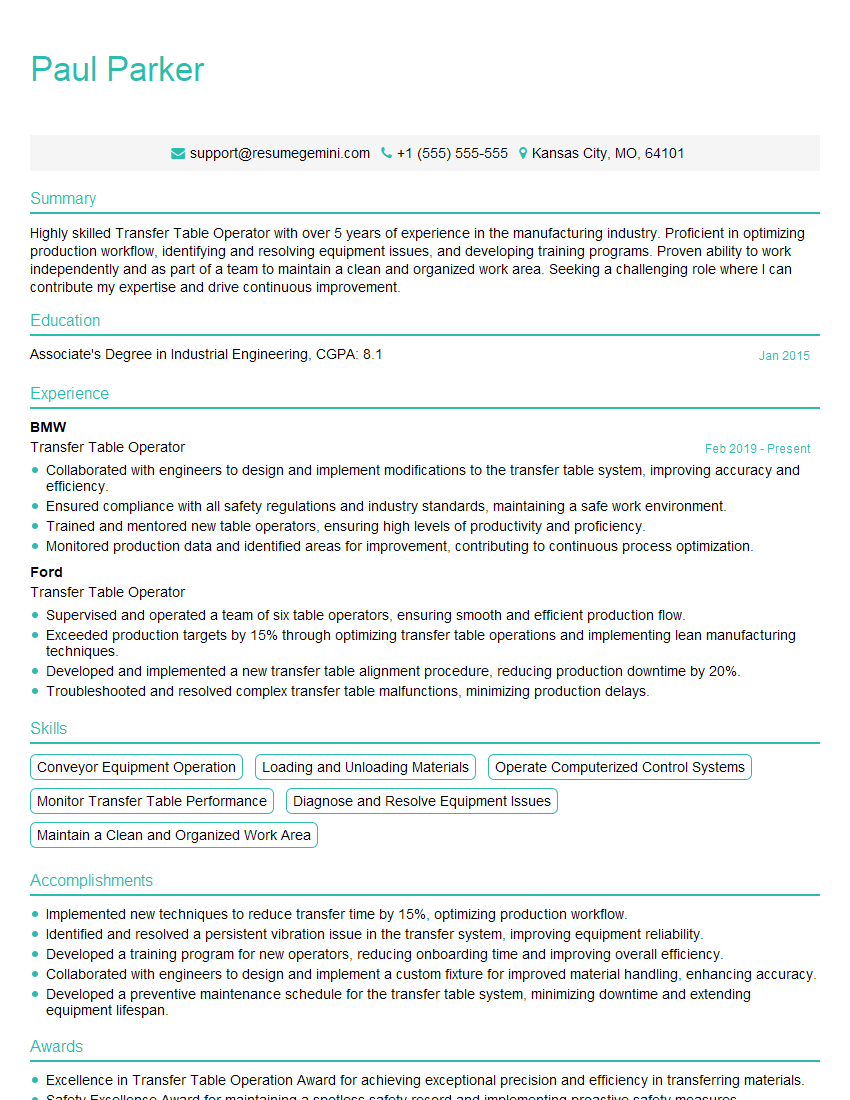

Paul Parker

Transfer Table Operator

Summary

Highly skilled Transfer Table Operator with over 5 years of experience in the manufacturing industry. Proficient in optimizing production workflow, identifying and resolving equipment issues, and developing training programs. Proven ability to work independently and as part of a team to maintain a clean and organized work area. Seeking a challenging role where I can contribute my expertise and drive continuous improvement.

Education

Associate’s Degree in Industrial Engineering

January 2015

Skills

- Conveyor Equipment Operation

- Loading and Unloading Materials

- Operate Computerized Control Systems

- Monitor Transfer Table Performance

- Diagnose and Resolve Equipment Issues

- Maintain a Clean and Organized Work Area

Work Experience

Transfer Table Operator

- Collaborated with engineers to design and implement modifications to the transfer table system, improving accuracy and efficiency.

- Ensured compliance with all safety regulations and industry standards, maintaining a safe work environment.

- Trained and mentored new table operators, ensuring high levels of productivity and proficiency.

- Monitored production data and identified areas for improvement, contributing to continuous process optimization.

Transfer Table Operator

- Supervised and operated a team of six table operators, ensuring smooth and efficient production flow.

- Exceeded production targets by 15% through optimizing transfer table operations and implementing lean manufacturing techniques.

- Developed and implemented a new transfer table alignment procedure, reducing production downtime by 20%.

- Troubleshooted and resolved complex transfer table malfunctions, minimizing production delays.

Accomplishments

- Implemented new techniques to reduce transfer time by 15%, optimizing production workflow.

- Identified and resolved a persistent vibration issue in the transfer system, improving equipment reliability.

- Developed a training program for new operators, reducing onboarding time and improving overall efficiency.

- Collaborated with engineers to design and implement a custom fixture for improved material handling, enhancing accuracy.

- Developed a preventive maintenance schedule for the transfer table system, minimizing downtime and extending equipment lifespan.

Awards

- Excellence in Transfer Table Operation Award for achieving exceptional precision and efficiency in transferring materials.

- Safety Excellence Award for maintaining a spotless safety record and implementing proactive safety measures.

- Top Performer Award for consistently exceeding production targets and demonstrating a commitment to quality.

- Employee of the Month for exemplary performance and dedication to the role of Transfer Table Operator.

Certificates

- Certified Transfer Table Operator (CTTO)

- National Center for Construction Education and Research (NCCER) Transfer Table Operator Certification

- OSHA 30Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Transfer Table Operator

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Highlight your ability to collaborate with engineers and other departments.

- Showcase your knowledge of conveyor equipment and computerized control systems.

- Emphasize your commitment to safety and adherence to quality standards.

Essential Experience Highlights for a Strong Transfer Table Operator Resume

- Operate and maintain transfer table systems to ensure efficient material handling and production flow.

- Monitor transfer table performance, diagnose and resolve any equipment issues promptly.

- Implement new techniques and procedures to optimize transfer time and improve production efficiency.

- Develop and implement preventive maintenance schedules to minimize downtime and extend equipment lifespan.

- Collaborate with engineers and other departments to improve equipment design and functionality.

- Train and mentor new operators to ensure proper operation and safety protocols.

- Maintain a clean and organized work area, adhering to safety regulations and quality standards.

Frequently Asked Questions (FAQ’s) For Transfer Table Operator

What is the primary function of a Transfer Table Operator?

Transfer Table Operators are responsible for operating and maintaining transfer table systems, which facilitate the efficient movement of materials and products throughout a manufacturing facility. They monitor the performance of the system, identify and resolve any issues, and implement new techniques to optimize production flow.

What skills are required to be a successful Transfer Table Operator?

Successful Transfer Table Operators possess strong operational skills for conveyor equipment and computerized control systems. They have a keen eye for detail, excellent problem-solving abilities, and a commitment to safety and quality. Additionally, they may have experience in developing and implementing training programs.

What are the career opportunities for a Transfer Table Operator?

Transfer Table Operators can advance their careers by specializing in specific areas such as equipment maintenance, process improvement, or training and development. They may also move into supervisory or management roles within the manufacturing industry.

What is the work environment like for a Transfer Table Operator?

Transfer Table Operators typically work in manufacturing facilities, often in a fast-paced and physically demanding environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production demands.

What are the safety precautions that Transfer Table Operators should follow?

Transfer Table Operators must adhere to all safety regulations and procedures, including wearing appropriate personal protective equipment, maintaining a clean and organized work area, and following lockout/tagout procedures when servicing equipment. They must also be aware of potential hazards, such as moving machinery and electrical components.

How can I prepare for a career as a Transfer Table Operator?

To prepare for a career as a Transfer Table Operator, you can pursue an associate’s degree in industrial engineering or a related field. You can also gain experience by working in a manufacturing environment or completing internships or apprenticeships. Additionally, obtaining certifications in conveyor equipment operation and maintenance can enhance your qualifications.