Are you a seasoned Trim Die Maker seeking a new career path? Discover our professionally built Trim Die Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

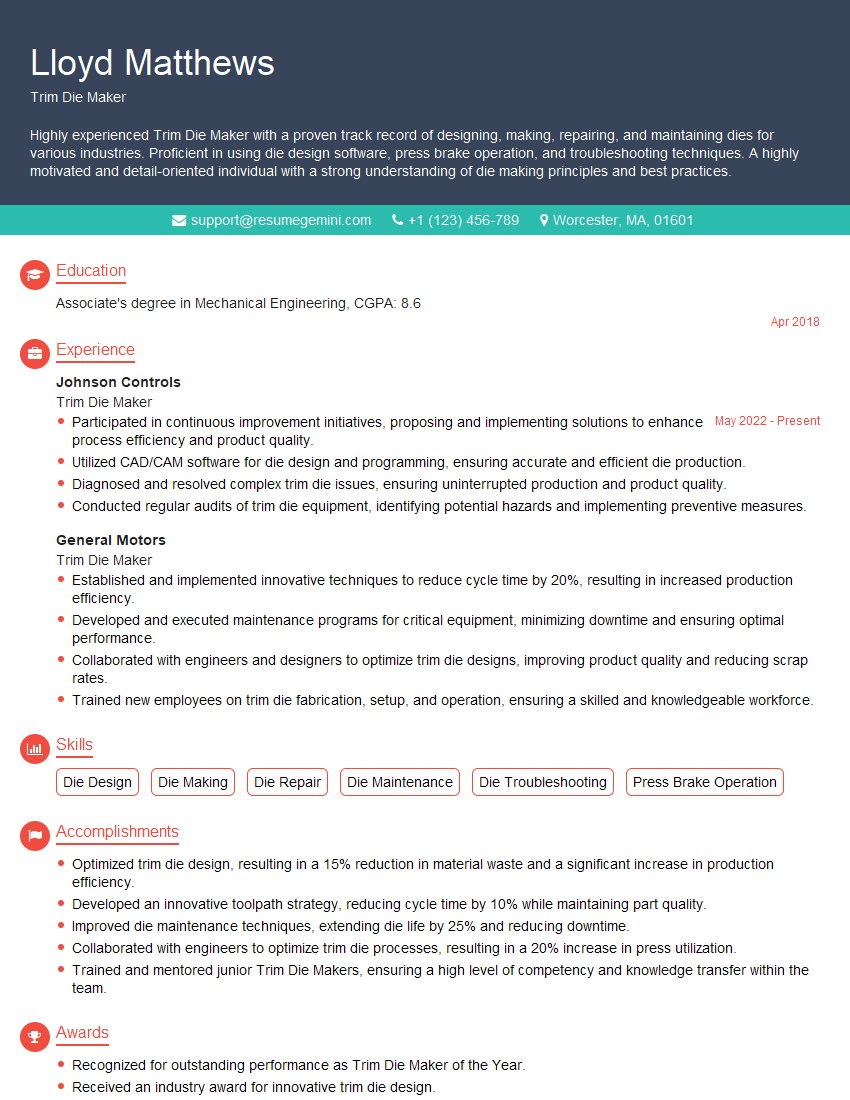

Lloyd Matthews

Trim Die Maker

Summary

Highly experienced Trim Die Maker with a proven track record of designing, making, repairing, and maintaining dies for various industries. Proficient in using die design software, press brake operation, and troubleshooting techniques. A highly motivated and detail-oriented individual with a strong understanding of die making principles and best practices.

Education

Associate’s degree in Mechanical Engineering

April 2018

Skills

- Die Design

- Die Making

- Die Repair

- Die Maintenance

- Die Troubleshooting

- Press Brake Operation

Work Experience

Trim Die Maker

- Participated in continuous improvement initiatives, proposing and implementing solutions to enhance process efficiency and product quality.

- Utilized CAD/CAM software for die design and programming, ensuring accurate and efficient die production.

- Diagnosed and resolved complex trim die issues, ensuring uninterrupted production and product quality.

- Conducted regular audits of trim die equipment, identifying potential hazards and implementing preventive measures.

Trim Die Maker

- Established and implemented innovative techniques to reduce cycle time by 20%, resulting in increased production efficiency.

- Developed and executed maintenance programs for critical equipment, minimizing downtime and ensuring optimal performance.

- Collaborated with engineers and designers to optimize trim die designs, improving product quality and reducing scrap rates.

- Trained new employees on trim die fabrication, setup, and operation, ensuring a skilled and knowledgeable workforce.

Accomplishments

- Optimized trim die design, resulting in a 15% reduction in material waste and a significant increase in production efficiency.

- Developed an innovative toolpath strategy, reducing cycle time by 10% while maintaining part quality.

- Improved die maintenance techniques, extending die life by 25% and reducing downtime.

- Collaborated with engineers to optimize trim die processes, resulting in a 20% increase in press utilization.

- Trained and mentored junior Trim Die Makers, ensuring a high level of competency and knowledge transfer within the team.

Awards

- Recognized for outstanding performance as Trim Die Maker of the Year.

- Received an industry award for innovative trim die design.

- Commended for exceptional contributions to the field of Trim Die Making.

Certificates

- Certified Tool and Die Maker

- Certified Die Designer

- Certified Press Brake Operator

- Certified CNC Programmer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Trim Die Maker

- Highlight your skills in die design and die making software.

- Quantify your accomplishments with specific metrics, such as the number of dies designed or repaired.

- Showcase your problem-solving abilities and experience in troubleshooting die-related issues.

- Emphasize your attention to detail and commitment to producing high-quality dies.

Essential Experience Highlights for a Strong Trim Die Maker Resume

- Design and develop trim dies according to product specifications and engineering drawings.

- Fabricate and assemble trim dies using a variety of tools and equipment.

- Repair and maintain trim dies to ensure optimal performance and prevent breakdowns.

- Troubleshoot and resolve die-related issues to minimize downtime and maintain production efficiency.

- Operate press brakes to form and trim metal parts to precise specifications.

- Collaborate with engineers, designers, and other team members to develop and improve die designs and processes.

Frequently Asked Questions (FAQ’s) For Trim Die Maker

What is the role of a Trim Die Maker?

A Trim Die Maker is responsible for designing, making, repairing, and maintaining trim dies used in the manufacturing process to cut and form metal parts.

What are the key skills required for a Trim Die Maker?

The key skills required for a Trim Die Maker include die design, die making, die repair, die maintenance, die troubleshooting, and press brake operation.

What industries employ Trim Die Makers?

Trim Die Makers are employed in a variety of industries, including automotive, aerospace, electronics, and appliance manufacturing.

What is the typical work environment for a Trim Die Maker?

Trim Die Makers typically work in a manufacturing environment, often in a workshop or factory setting.

What are the career advancement opportunities for a Trim Die Maker?

With experience and additional training, Trim Die Makers can advance to positions such as Die Design Engineer, Tooling Engineer, or Production Supervisor.

What is the average salary for a Trim Die Maker?

The average salary for a Trim Die Maker varies depending on experience, location, and industry, but typically ranges from $25,000 to $75,000 per year.

What is the job outlook for Trim Die Makers?

The job outlook for Trim Die Makers is expected to be good in the coming years, as the demand for skilled manufacturing workers continues to grow.