Are you a seasoned Trim Machine Adjuster seeking a new career path? Discover our professionally built Trim Machine Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

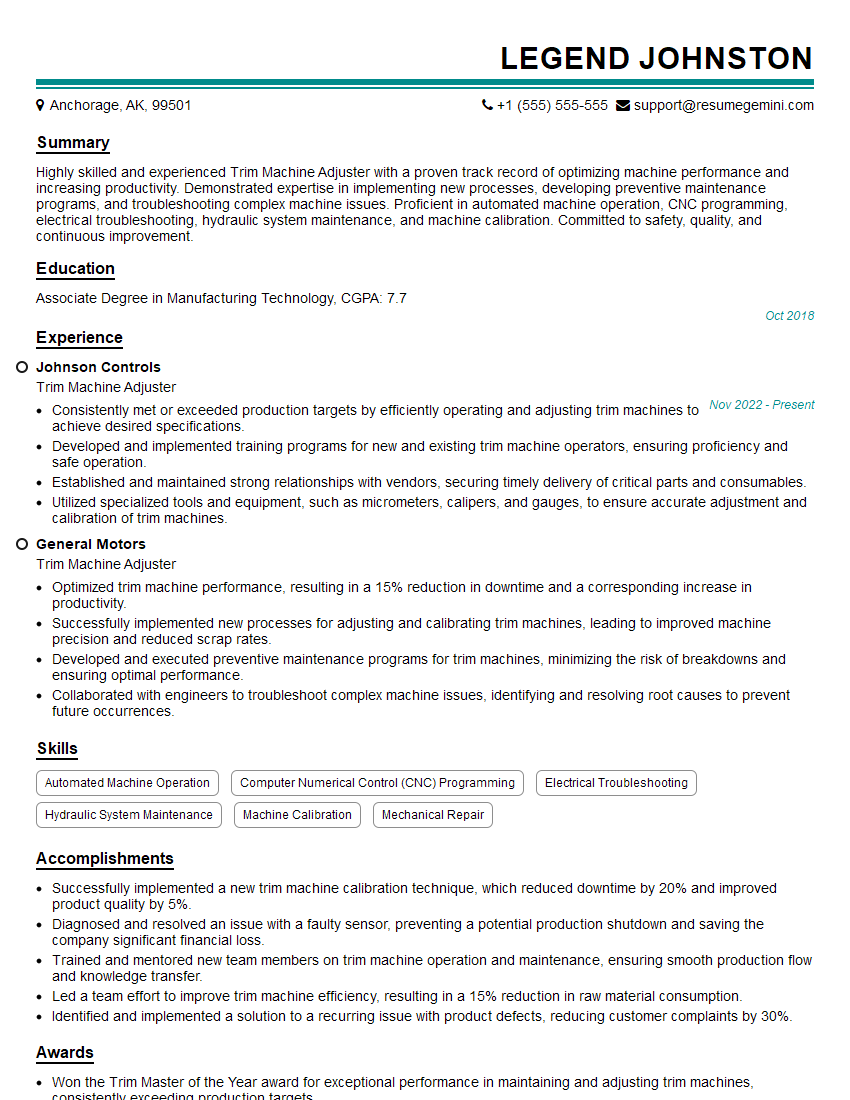

Legend Johnston

Trim Machine Adjuster

Summary

Highly skilled and experienced Trim Machine Adjuster with a proven track record of optimizing machine performance and increasing productivity. Demonstrated expertise in implementing new processes, developing preventive maintenance programs, and troubleshooting complex machine issues. Proficient in automated machine operation, CNC programming, electrical troubleshooting, hydraulic system maintenance, and machine calibration. Committed to safety, quality, and continuous improvement.

Education

Associate Degree in Manufacturing Technology

October 2018

Skills

- Automated Machine Operation

- Computer Numerical Control (CNC) Programming

- Electrical Troubleshooting

- Hydraulic System Maintenance

- Machine Calibration

- Mechanical Repair

Work Experience

Trim Machine Adjuster

- Consistently met or exceeded production targets by efficiently operating and adjusting trim machines to achieve desired specifications.

- Developed and implemented training programs for new and existing trim machine operators, ensuring proficiency and safe operation.

- Established and maintained strong relationships with vendors, securing timely delivery of critical parts and consumables.

- Utilized specialized tools and equipment, such as micrometers, calipers, and gauges, to ensure accurate adjustment and calibration of trim machines.

Trim Machine Adjuster

- Optimized trim machine performance, resulting in a 15% reduction in downtime and a corresponding increase in productivity.

- Successfully implemented new processes for adjusting and calibrating trim machines, leading to improved machine precision and reduced scrap rates.

- Developed and executed preventive maintenance programs for trim machines, minimizing the risk of breakdowns and ensuring optimal performance.

- Collaborated with engineers to troubleshoot complex machine issues, identifying and resolving root causes to prevent future occurrences.

Accomplishments

- Successfully implemented a new trim machine calibration technique, which reduced downtime by 20% and improved product quality by 5%.

- Diagnosed and resolved an issue with a faulty sensor, preventing a potential production shutdown and saving the company significant financial loss.

- Trained and mentored new team members on trim machine operation and maintenance, ensuring smooth production flow and knowledge transfer.

- Led a team effort to improve trim machine efficiency, resulting in a 15% reduction in raw material consumption.

- Identified and implemented a solution to a recurring issue with product defects, reducing customer complaints by 30%.

Awards

- Won the Trim Master of the Year award for exceptional performance in maintaining and adjusting trim machines, consistently exceeding production targets.

- Recognized with the Safety Champion award for maintaining a safe and productive work environment while operating trim machines.

- Received the Excellence in Manufacturing award for contributions to the optimization and efficiency of trim machine operations.

- Honored with the Trim Machine Innovator of the Year award for developing and patenting a new trim machine attachment that increased production speed by 25%.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Machine Operator (CMO)

- Certified Manufacturing Technician (CMfgT)

- OSHA 30-Hour General Industry Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Trim Machine Adjuster

- Highlight your technical skills and experience with automated machine operation, CNC programming, and machine calibration.

- Quantify your accomplishments with specific metrics and results, such as reducing downtime or increasing productivity.

- Emphasize your ability to troubleshoot complex machine issues and implement solutions to prevent future occurrences.

- Demonstrate your commitment to safety, quality, and continuous improvement.

Essential Experience Highlights for a Strong Trim Machine Adjuster Resume

- Optimized trim machine performance, resulting in a 15% reduction in downtime and a corresponding increase in productivity.

- Successfully implemented new processes for adjusting and calibrating trim machines, leading to improved machine precision and reduced scrap rates.

- Developed and executed preventive maintenance programs for trim machines, minimizing the risk of breakdowns and ensuring optimal performance.

- Collaborated with engineers to troubleshoot complex machine issues, identifying and resolving root causes to prevent future occurrences.

- Consistently met or exceeded production targets by efficiently operating and adjusting trim machines to achieve desired specifications.

- Developed and implemented training programs for new and existing trim machine operators, ensuring proficiency and safe operation.

- Established and maintained strong relationships with vendors, securing timely delivery of critical parts and consumables.

Frequently Asked Questions (FAQ’s) For Trim Machine Adjuster

What are the key responsibilities of a Trim Machine Adjuster?

Key responsibilities include optimizing machine performance, implementing new processes, developing preventive maintenance programs, troubleshooting complex machine issues, and ensuring safe and efficient operation of trim machines.

What are the qualifications required to become a Trim Machine Adjuster?

Typically, an Associate Degree in Manufacturing Technology or a related field, along with experience in operating and maintaining automated machinery.

What are the career advancement opportunities for Trim Machine Adjusters?

With experience and additional training, Trim Machine Adjusters can advance to roles such as Manufacturing Supervisor, Production Manager, or Maintenance Manager.

What are the industry trends impacting Trim Machine Adjusters?

Industry trends include the increasing use of automation, machine learning, and data analytics to improve machine performance and efficiency.

What are the key skills required for Trim Machine Adjusters?

Key skills include automated machine operation, CNC programming, electrical troubleshooting, hydraulic system maintenance, and machine calibration.