Are you a seasoned Trimming Assembler seeking a new career path? Discover our professionally built Trimming Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

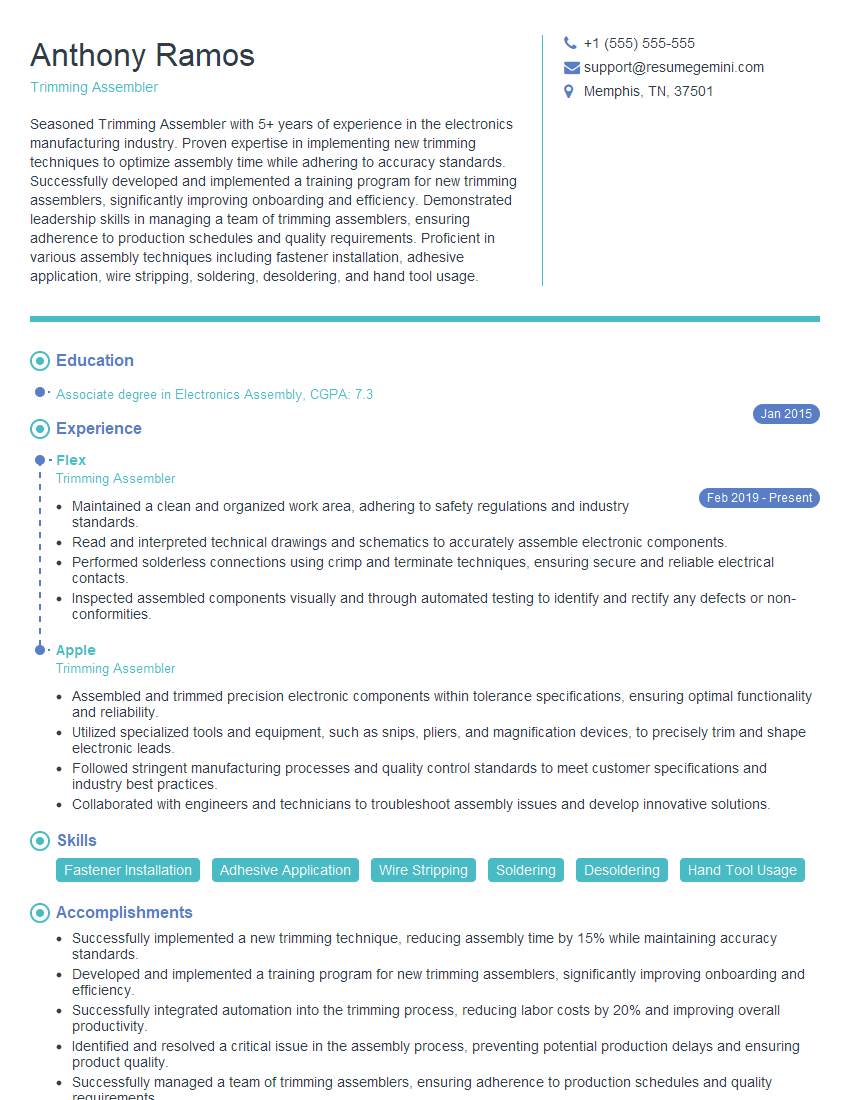

Anthony Ramos

Trimming Assembler

Summary

Seasoned Trimming Assembler with 5+ years of experience in the electronics manufacturing industry. Proven expertise in implementing new trimming techniques to optimize assembly time while adhering to accuracy standards. Successfully developed and implemented a training program for new trimming assemblers, significantly improving onboarding and efficiency. Demonstrated leadership skills in managing a team of trimming assemblers, ensuring adherence to production schedules and quality requirements. Proficient in various assembly techniques including fastener installation, adhesive application, wire stripping, soldering, desoldering, and hand tool usage.

Education

Associate degree in Electronics Assembly

January 2015

Skills

- Fastener Installation

- Adhesive Application

- Wire Stripping

- Soldering

- Desoldering

- Hand Tool Usage

Work Experience

Trimming Assembler

- Maintained a clean and organized work area, adhering to safety regulations and industry standards.

- Read and interpreted technical drawings and schematics to accurately assemble electronic components.

- Performed solderless connections using crimp and terminate techniques, ensuring secure and reliable electrical contacts.

- Inspected assembled components visually and through automated testing to identify and rectify any defects or non-conformities.

Trimming Assembler

- Assembled and trimmed precision electronic components within tolerance specifications, ensuring optimal functionality and reliability.

- Utilized specialized tools and equipment, such as snips, pliers, and magnification devices, to precisely trim and shape electronic leads.

- Followed stringent manufacturing processes and quality control standards to meet customer specifications and industry best practices.

- Collaborated with engineers and technicians to troubleshoot assembly issues and develop innovative solutions.

Accomplishments

- Successfully implemented a new trimming technique, reducing assembly time by 15% while maintaining accuracy standards.

- Developed and implemented a training program for new trimming assemblers, significantly improving onboarding and efficiency.

- Successfully integrated automation into the trimming process, reducing labor costs by 20% and improving overall productivity.

- Identified and resolved a critical issue in the assembly process, preventing potential production delays and ensuring product quality.

- Successfully managed a team of trimming assemblers, ensuring adherence to production schedules and quality requirements.

Awards

- Recognized for outstanding performance and dedication to maintaining highquality standards in trimming and assembly processes.

- Received a departmental award for exceptional safety record and adherence to workplace safety protocols.

- Recognized for innovative suggestions that led to process improvements and enhanced production efficiency.

- Received a peernominated award for exceptional teamwork and collaboration in achieving production goals.

Certificates

- IPCA610 Acceptability of Electronic Assemblies

- IPC612 Printed Board Design

- IPC7711 Rework, Modification and Repair of Electronic Assemblies

- OSHA 30Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Trimming Assembler

- Highlight your experience in implementing new trimming techniques and quantifying the results.

- Emphasize your ability to develop and deliver effective training programs for new trimming assemblers.

- Showcase your leadership skills and ability to manage a team in a fast-paced manufacturing environment.

- Demonstrate your proficiency in various assembly techniques and your commitment to maintaining high-quality standards.

Essential Experience Highlights for a Strong Trimming Assembler Resume

- Implement new trimming techniques to reduce assembly time while maintaining accuracy standards.

- Develop and implement training programs for new trimming assemblers to improve onboarding and efficiency.

- Integrate automation into the trimming process to reduce labor costs and enhance productivity.

- Identify and resolve critical issues in the assembly process to prevent potential production delays and ensure product quality.

- Manage a team of trimming assemblers to ensure adherence to production schedules and quality requirements.

- Conduct regular quality checks to ensure the accuracy and precision of assembled components.

- Collaborate with engineering and design teams to provide feedback on process improvements and new product development.

Frequently Asked Questions (FAQ’s) For Trimming Assembler

What are the key skills required to be a successful Trimming Assembler?

Key skills include fastener installation, adhesive application, wire stripping, soldering, desoldering, and hand tool usage. Additionally, proficiency in reading and interpreting technical drawings and specifications is essential.

What are the career advancement opportunities for Trimming Assemblers?

With experience and additional training, Trimming Assemblers can advance to roles such as Assembly Supervisor, Production Manager, or Quality Control Inspector.

What is the work environment like for Trimming Assemblers?

Trimming Assemblers typically work in manufacturing facilities, often in clean and well-lit environments. The work can be physically demanding, requiring standing for long periods and performing repetitive tasks.

What are the safety precautions that Trimming Assemblers must follow?

Trimming Assemblers must wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and anti-static clothing. They must also be aware of potential hazards such as sharp tools, electrical equipment, and chemicals.

How can I prepare for a career as a Trimming Assembler?

Consider obtaining an associate degree in Electronics Assembly or a related field. Additionally, gaining experience through internships or apprenticeships can be beneficial.

What is the job outlook for Trimming Assemblers?

The job outlook for Trimming Assemblers is expected to be favorable in the coming years, driven by the increasing demand for electronic devices and components.

What are the earning expectations for Trimming Assemblers?

Earning expectations can vary depending on factors such as experience, location, and company size. However, Trimming Assemblers can generally expect to earn a competitive wage.