Are you a seasoned Tube and Manifold Builder seeking a new career path? Discover our professionally built Tube and Manifold Builder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

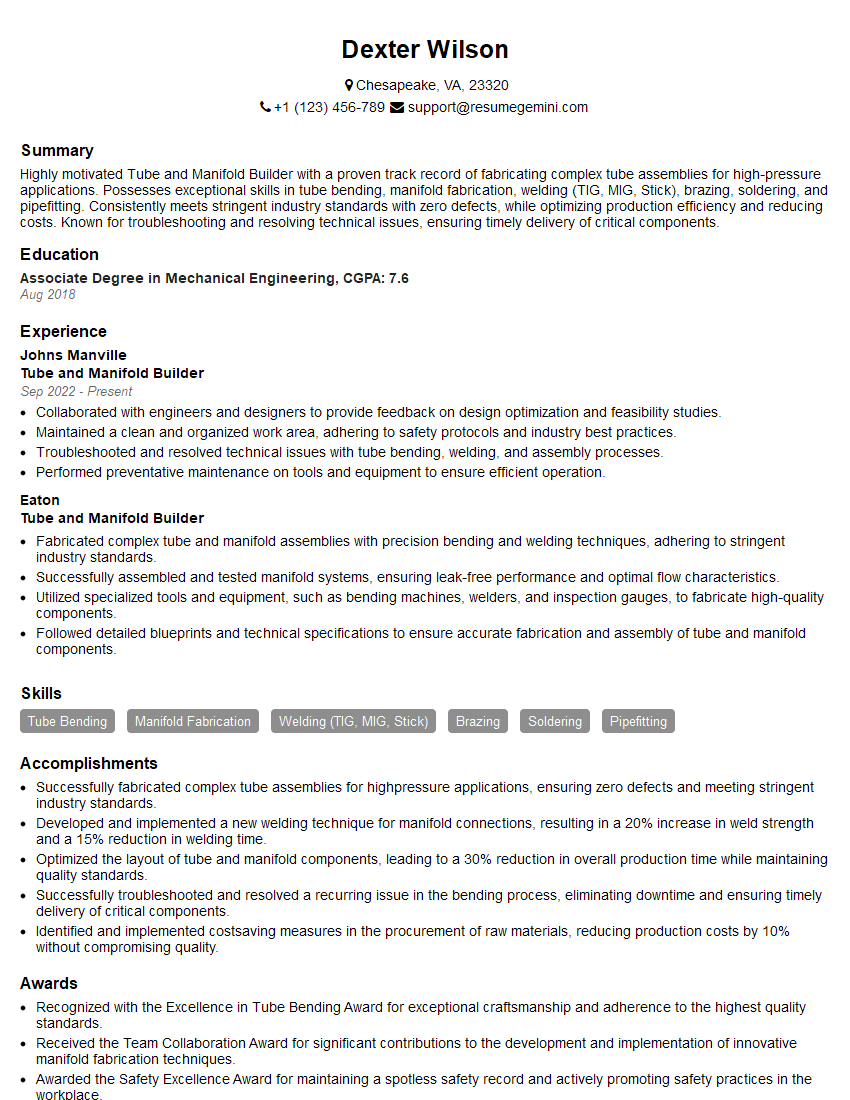

Dexter Wilson

Tube and Manifold Builder

Summary

Highly motivated Tube and Manifold Builder with a proven track record of fabricating complex tube assemblies for high-pressure applications. Possesses exceptional skills in tube bending, manifold fabrication, welding (TIG, MIG, Stick), brazing, soldering, and pipefitting. Consistently meets stringent industry standards with zero defects, while optimizing production efficiency and reducing costs. Known for troubleshooting and resolving technical issues, ensuring timely delivery of critical components.

Education

Associate Degree in Mechanical Engineering

August 2018

Skills

- Tube Bending

- Manifold Fabrication

- Welding (TIG, MIG, Stick)

- Brazing

- Soldering

- Pipefitting

Work Experience

Tube and Manifold Builder

- Collaborated with engineers and designers to provide feedback on design optimization and feasibility studies.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

- Troubleshooted and resolved technical issues with tube bending, welding, and assembly processes.

- Performed preventative maintenance on tools and equipment to ensure efficient operation.

Tube and Manifold Builder

- Fabricated complex tube and manifold assemblies with precision bending and welding techniques, adhering to stringent industry standards.

- Successfully assembled and tested manifold systems, ensuring leak-free performance and optimal flow characteristics.

- Utilized specialized tools and equipment, such as bending machines, welders, and inspection gauges, to fabricate high-quality components.

- Followed detailed blueprints and technical specifications to ensure accurate fabrication and assembly of tube and manifold components.

Accomplishments

- Successfully fabricated complex tube assemblies for highpressure applications, ensuring zero defects and meeting stringent industry standards.

- Developed and implemented a new welding technique for manifold connections, resulting in a 20% increase in weld strength and a 15% reduction in welding time.

- Optimized the layout of tube and manifold components, leading to a 30% reduction in overall production time while maintaining quality standards.

- Successfully troubleshooted and resolved a recurring issue in the bending process, eliminating downtime and ensuring timely delivery of critical components.

- Identified and implemented costsaving measures in the procurement of raw materials, reducing production costs by 10% without compromising quality.

Awards

- Recognized with the Excellence in Tube Bending Award for exceptional craftsmanship and adherence to the highest quality standards.

- Received the Team Collaboration Award for significant contributions to the development and implementation of innovative manifold fabrication techniques.

- Awarded the Safety Excellence Award for maintaining a spotless safety record and actively promoting safety practices in the workplace.

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

- National Institute for Metalworking Skills (NIMS)

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tube and Manifold Builder

- Highlight your proficiency in various welding techniques, including TIG, MIG, and Stick welding.

- Showcase your problem-solving abilities by providing specific examples of how you have overcome challenges in the fabrication process.

- Quantify your accomplishments whenever possible, using metrics such as reduced production time, increased weld strength, or cost savings.

- Emphasize your commitment to quality by mentioning your zero-defect record and adherence to industry standards.

- Tailor your resume to each job application by highlighting the skills and experience that are most relevant to the specific role.

Essential Experience Highlights for a Strong Tube and Manifold Builder Resume

- Fabricate and assemble complex tube and manifold components according to design specifications and industry standards

- Utilize various welding techniques (TIG, MIG, Stick), brazing, and soldering to create durable and leak-proof connections

- Operate tube bending machines to precisely shape and form tubes to meet required dimensions and angles

- Cut, thread, and fit tubes and manifolds using pipefitting tools and equipment

- Inspect and test assemblies to ensure they meet quality standards and perform as intended

- Troubleshoot and resolve technical issues that arise during the fabrication process

- Collaborate with engineers and designers to refine designs and improve production efficiency

Frequently Asked Questions (FAQ’s) For Tube and Manifold Builder

What are the primary responsibilities of a Tube and Manifold Builder?

Tube and Manifold Builders are responsible for fabricating, assembling, and testing tube and manifold components for a variety of industries, including automotive, aerospace, and construction. They utilize various welding techniques, such as TIG, MIG, and Stick welding, as well as other techniques like brazing and soldering to create durable and leak-proof connections.

What are the essential skills required for a successful Tube and Manifold Builder?

Essential skills for a Tube and Manifold Builder include proficiency in welding (TIG, MIG, Stick), brazing, and soldering. They should also have a strong understanding of tube bending techniques and be able to operate tube bending machines to precisely shape and form tubes. Additionally, knowledge of pipefitting and the ability to interpret technical drawings are valuable assets.

What type of education and training is needed to become a Tube and Manifold Builder?

While formal education requirements may vary depending on the industry and employer, many Tube and Manifold Builders have an Associate Degree in Mechanical Engineering or a related field. Additionally, on-the-job training and apprenticeships can provide valuable practical experience in this field.

What are the career advancement opportunities for a Tube and Manifold Builder?

With experience and additional training, Tube and Manifold Builders can advance to roles such as Lead Tube and Manifold Builder, Supervisor, or Quality Control Inspector. They may also specialize in a particular aspect of the field, such as welding or tube bending, and become experts in their chosen area.

What is the job outlook for Tube and Manifold Builders?

The job outlook for Tube and Manifold Builders is expected to be positive in the coming years. The increasing demand for fabricated metal components in various industries, including automotive, aerospace, and construction, is driving the need for skilled professionals in this field.

What are the salary expectations for a Tube and Manifold Builder?

Salary expectations for Tube and Manifold Builders can vary depending on experience, location, and industry. According to Indeed, the average salary for a Tube and Manifold Builder in the United States is around $25 per hour or $52,000 per year.

What are the benefits of working as a Tube and Manifold Builder?

Tube and Manifold Builders enjoy a stable and rewarding career with opportunities for growth and advancement. They work in a dynamic and challenging environment where they can apply their skills and knowledge to create high-quality components for various industries.