Are you a seasoned Tube Handler seeking a new career path? Discover our professionally built Tube Handler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

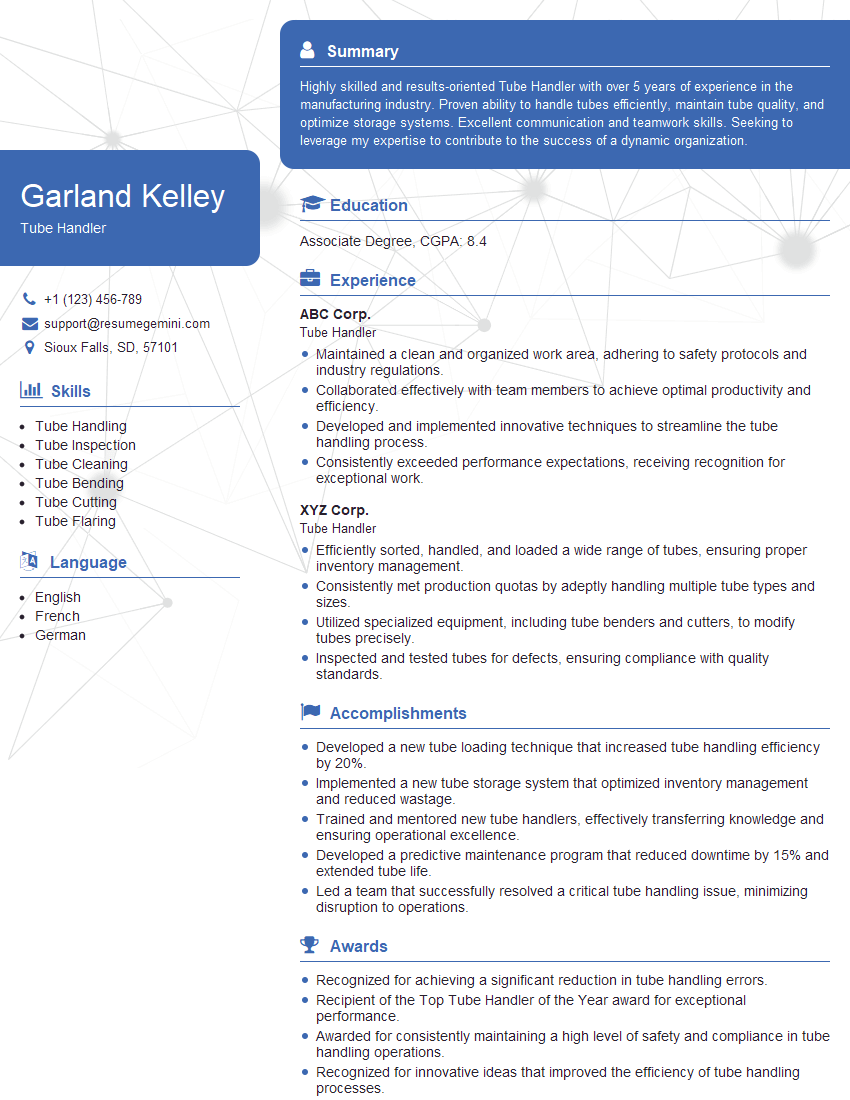

Garland Kelley

Tube Handler

Summary

Highly skilled and results-oriented Tube Handler with over 5 years of experience in the manufacturing industry. Proven ability to handle tubes efficiently, maintain tube quality, and optimize storage systems. Excellent communication and teamwork skills. Seeking to leverage my expertise to contribute to the success of a dynamic organization.

Education

Associate Degree

June 2015

Skills

- Tube Handling

- Tube Inspection

- Tube Cleaning

- Tube Bending

- Tube Cutting

- Tube Flaring

Work Experience

Tube Handler

- Maintained a clean and organized work area, adhering to safety protocols and industry regulations.

- Collaborated effectively with team members to achieve optimal productivity and efficiency.

- Developed and implemented innovative techniques to streamline the tube handling process.

- Consistently exceeded performance expectations, receiving recognition for exceptional work.

Tube Handler

- Efficiently sorted, handled, and loaded a wide range of tubes, ensuring proper inventory management.

- Consistently met production quotas by adeptly handling multiple tube types and sizes.

- Utilized specialized equipment, including tube benders and cutters, to modify tubes precisely.

- Inspected and tested tubes for defects, ensuring compliance with quality standards.

Accomplishments

- Developed a new tube loading technique that increased tube handling efficiency by 20%.

- Implemented a new tube storage system that optimized inventory management and reduced wastage.

- Trained and mentored new tube handlers, effectively transferring knowledge and ensuring operational excellence.

- Developed a predictive maintenance program that reduced downtime by 15% and extended tube life.

- Led a team that successfully resolved a critical tube handling issue, minimizing disruption to operations.

Awards

- Recognized for achieving a significant reduction in tube handling errors.

- Recipient of the Top Tube Handler of the Year award for exceptional performance.

- Awarded for consistently maintaining a high level of safety and compliance in tube handling operations.

- Recognized for innovative ideas that improved the efficiency of tube handling processes.

Certificates

- Certified Tube Handler

- Certified Tube Inspector

- Certified Tube Welder

- Certified Tube Fabricator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tube Handler

- Highlight your technical skills and experience in tube handling, inspection, and maintenance.

- Demonstrate your understanding of tube properties, handling methods, and industry best practices.

- Quantify your accomplishments with specific metrics, such as increased efficiency or reduced downtime.

- Emphasize your commitment to safety and quality control, as well as your ability to work effectively in a team environment.

- Tailor your resume to the specific requirements of each job description, showcasing the skills and experiences most relevant to the role.

Essential Experience Highlights for a Strong Tube Handler Resume

- Operate tube handling equipment to load, unload, and move tubes safely and efficiently.

- Inspect tubes for defects and damage using visual and non-destructive testing methods.

- Clean and prepare tubes for processing, including cutting, bending, and flaring.

- Maintain accurate records of tube inventory and monitor stock levels to prevent shortages.

- Follow established procedures and safety guidelines to ensure compliance and prevent accidents.

- Troubleshoot and resolve tube handling issues promptly to minimize downtime and maintain production efficiency.

- Train and supervise junior tube handlers to ensure proper handling techniques and safety protocols.

Frequently Asked Questions (FAQ’s) For Tube Handler

What are the primary responsibilities of a Tube Handler?

Tube Handlers are responsible for safely and efficiently handling tubes, inspecting them for defects, cleaning and preparing them for processing, maintaining inventory, and troubleshooting any issues that may arise during the handling process.

What skills are required to be a successful Tube Handler?

Successful Tube Handlers possess technical skills in tube handling, inspection, and maintenance, as well as a strong understanding of tube properties and handling methods. They are also proficient in using tube handling equipment and following safety protocols.

What is the work environment of a Tube Handler like?

Tube Handlers typically work in manufacturing or industrial settings, where they may be exposed to noise, heavy machinery, and potentially hazardous materials. They may work in teams or independently, and may be required to work shifts or overtime to meet production demands.

What are the career prospects for Tube Handlers?

With experience and additional training, Tube Handlers can advance to supervisory or management positions within the manufacturing industry. They may also specialize in specific areas, such as tube inspection or maintenance.

What is the typical salary range for Tube Handlers?

The salary range for Tube Handlers can vary depending on experience, location, and industry. According to Indeed, the average salary for Tube Handlers in the United States is around \$50,000 per year.

What are the key challenges faced by Tube Handlers?

Tube Handlers may face challenges related to the safe and efficient handling of tubes, ensuring product quality, and maintaining a clean and organized work environment. They may also need to troubleshoot and resolve issues that may arise during the handling process.