Are you a seasoned Tufting Creeler seeking a new career path? Discover our professionally built Tufting Creeler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

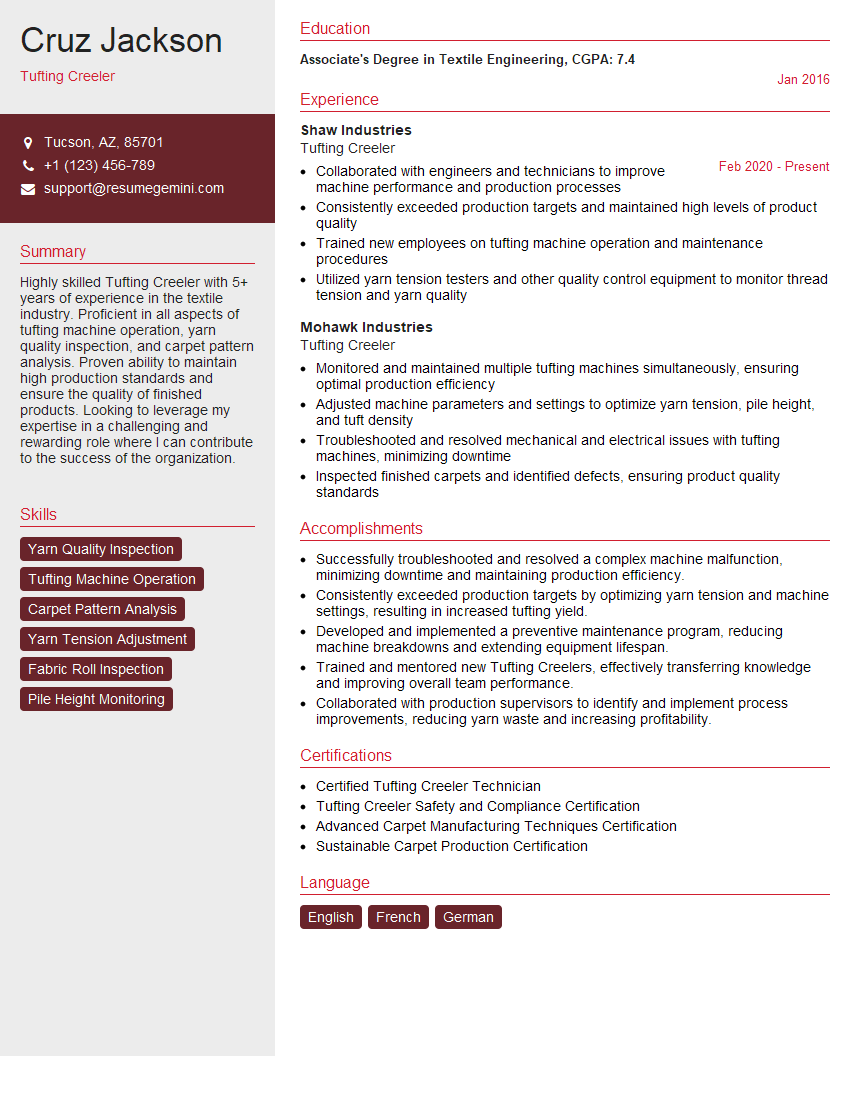

Cruz Jackson

Tufting Creeler

Summary

Highly skilled Tufting Creeler with 5+ years of experience in the textile industry. Proficient in all aspects of tufting machine operation, yarn quality inspection, and carpet pattern analysis. Proven ability to maintain high production standards and ensure the quality of finished products. Looking to leverage my expertise in a challenging and rewarding role where I can contribute to the success of the organization.

Education

Associate’s Degree in Textile Engineering

January 2016

Skills

- Yarn Quality Inspection

- Tufting Machine Operation

- Carpet Pattern Analysis

- Yarn Tension Adjustment

- Fabric Roll Inspection

- Pile Height Monitoring

Work Experience

Tufting Creeler

- Collaborated with engineers and technicians to improve machine performance and production processes

- Consistently exceeded production targets and maintained high levels of product quality

- Trained new employees on tufting machine operation and maintenance procedures

- Utilized yarn tension testers and other quality control equipment to monitor thread tension and yarn quality

Tufting Creeler

- Monitored and maintained multiple tufting machines simultaneously, ensuring optimal production efficiency

- Adjusted machine parameters and settings to optimize yarn tension, pile height, and tuft density

- Troubleshooted and resolved mechanical and electrical issues with tufting machines, minimizing downtime

- Inspected finished carpets and identified defects, ensuring product quality standards

Accomplishments

- Successfully troubleshooted and resolved a complex machine malfunction, minimizing downtime and maintaining production efficiency.

- Consistently exceeded production targets by optimizing yarn tension and machine settings, resulting in increased tufting yield.

- Developed and implemented a preventive maintenance program, reducing machine breakdowns and extending equipment lifespan.

- Trained and mentored new Tufting Creelers, effectively transferring knowledge and improving overall team performance.

- Collaborated with production supervisors to identify and implement process improvements, reducing yarn waste and increasing profitability.

Certificates

- Certified Tufting Creeler Technician

- Tufting Creeler Safety and Compliance Certification

- Advanced Carpet Manufacturing Techniques Certification

- Sustainable Carpet Production Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tufting Creeler

- Highlight your experience and skills in yarn quality inspection and tufting machine operation.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your ability to work independently and as part of a team.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

Essential Experience Highlights for a Strong Tufting Creeler Resume

- Set up and operate tufting machines according to specified patterns and specifications.

- Inspect yarn for quality and ensure it meets the required standards.

- Analyze carpet patterns and adjust yarn tension to achieve the desired pile height and density.

- Monitor fabric rolls for defects and ensure they meet quality standards.

- Troubleshoot and resolve machine malfunctions and yarn issues.

- Maintain a clean and organized work area.

- Adhere to all safety protocols and regulations.

- Work effectively as part of a team and follow the instructions of supervisors.

Frequently Asked Questions (FAQ’s) For Tufting Creeler

What is the primary role of a Tufting Creeler?

The primary role of a Tufting Creeler is to operate tufting machines to create carpets and other textile products. They are responsible for ensuring the quality of the yarn used, setting up and operating the tufting machines, and inspecting the finished products.

What are the key skills required for a Tufting Creeler?

Key skills required for a Tufting Creeler include yarn quality inspection, tufting machine operation, carpet pattern analysis, yarn tension adjustment, fabric roll inspection, and pile height monitoring.

What is the work environment of a Tufting Creeler like?

Tufting Creelers typically work in manufacturing facilities where they operate tufting machines and inspect carpets. The work environment can be noisy and dusty, and Tufting Creelers may be required to work long hours and overtime to meet production demands.

What are the career prospects for a Tufting Creeler?

Tufting Creelers can advance to positions such as Tufting Machine Operator, Carpet Inspector, or Production Supervisor. With additional training and experience, they may also be able to move into management or technical roles.

What is the average salary for a Tufting Creeler?

The average salary for a Tufting Creeler in the United States is around $35,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the benefits of working as a Tufting Creeler?

Benefits of working as a Tufting Creeler include job security, opportunities for advancement, and a sense of accomplishment. Tufting Creelers play an important role in the production of carpets and other textile products, and their work is essential to the success of the industry.