Are you a seasoned Tumbling Machine Operator seeking a new career path? Discover our professionally built Tumbling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

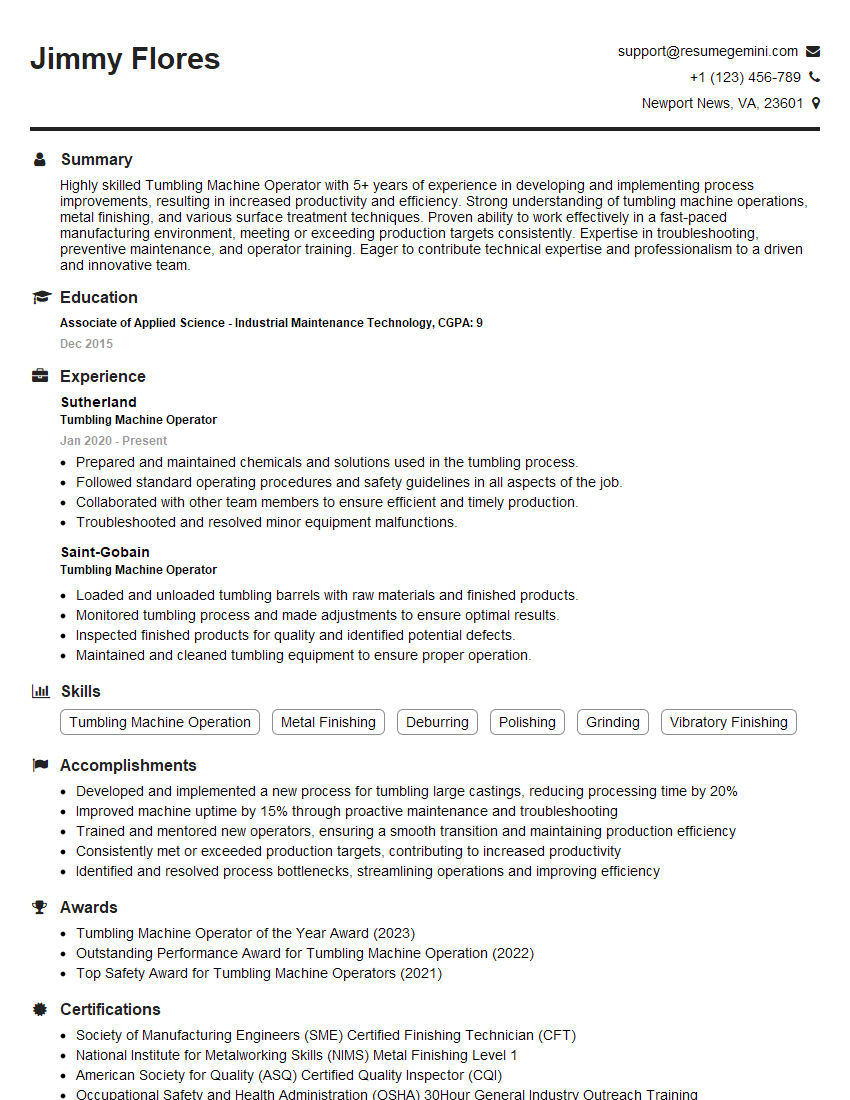

Jimmy Flores

Tumbling Machine Operator

Summary

Highly skilled Tumbling Machine Operator with 5+ years of experience in developing and implementing process improvements, resulting in increased productivity and efficiency. Strong understanding of tumbling machine operations, metal finishing, and various surface treatment techniques. Proven ability to work effectively in a fast-paced manufacturing environment, meeting or exceeding production targets consistently. Expertise in troubleshooting, preventive maintenance, and operator training. Eager to contribute technical expertise and professionalism to a driven and innovative team.

Education

Associate of Applied Science – Industrial Maintenance Technology

December 2015

Skills

- Tumbling Machine Operation

- Metal Finishing

- Deburring

- Polishing

- Grinding

- Vibratory Finishing

Work Experience

Tumbling Machine Operator

- Prepared and maintained chemicals and solutions used in the tumbling process.

- Followed standard operating procedures and safety guidelines in all aspects of the job.

- Collaborated with other team members to ensure efficient and timely production.

- Troubleshooted and resolved minor equipment malfunctions.

Tumbling Machine Operator

- Loaded and unloaded tumbling barrels with raw materials and finished products.

- Monitored tumbling process and made adjustments to ensure optimal results.

- Inspected finished products for quality and identified potential defects.

- Maintained and cleaned tumbling equipment to ensure proper operation.

Accomplishments

- Developed and implemented a new process for tumbling large castings, reducing processing time by 20%

- Improved machine uptime by 15% through proactive maintenance and troubleshooting

- Trained and mentored new operators, ensuring a smooth transition and maintaining production efficiency

- Consistently met or exceeded production targets, contributing to increased productivity

- Identified and resolved process bottlenecks, streamlining operations and improving efficiency

Awards

- Tumbling Machine Operator of the Year Award (2023)

- Outstanding Performance Award for Tumbling Machine Operation (2022)

- Top Safety Award for Tumbling Machine Operators (2021)

Certificates

- Society of Manufacturing Engineers (SME) Certified Finishing Technician (CFT)

- National Institute for Metalworking Skills (NIMS) Metal Finishing Level 1

- American Society for Quality (ASQ) Certified Quality Inspector (CQI)

- Occupational Safety and Health Administration (OSHA) 30Hour General Industry Outreach Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tumbling Machine Operator

- Highlight your technical expertise in tumbling machine operations, metal finishing techniques, and process optimization.

- Emphasize your ability to work effectively in a fast-paced manufacturing environment and meet or exceed production targets.

- Showcase your problem-solving skills, including troubleshooting, preventive maintenance, and process improvement initiatives.

- Demonstrate your commitment to safety, quality control, and continuous improvement in your work experience and skills section.

Essential Experience Highlights for a Strong Tumbling Machine Operator Resume

- Operate and maintain tumbling machines, ensuring optimal performance and adherence to safety protocols

- Develop and implement process improvements to enhance efficiency, reduce production time, and minimize defects

- Conduct routine inspections, preventive maintenance, and troubleshooting to maintain machine uptime and prevent breakdowns

- Train and mentor new operators, ensuring smooth transitions and effective knowledge transfer

- Collaborate with production and engineering teams to identify and resolve process bottlenecks, optimize operations, and improve overall productivity

- Monitor and maintain inventory levels of consumables, such as abrasives, polishing compounds, and chemicals, to ensure uninterrupted operations

Frequently Asked Questions (FAQ’s) For Tumbling Machine Operator

What are the primary responsibilities of a Tumbling Machine Operator?

Tumbling Machine Operators are responsible for operating and maintaining tumbling machines, developing and implementing process improvements, conducting preventive maintenance and troubleshooting, training new operators, and ensuring adherence to safety protocols.

What are the key skills required for a Tumbling Machine Operator?

Essential skills for Tumbling Machine Operators include proficiency in tumbling machine operations, metal finishing techniques, preventive maintenance, troubleshooting, and process optimization.

What industries employ Tumbling Machine Operators?

Tumbling Machine Operators are employed in various industries, including metal fabrication, automotive, aerospace, and manufacturing.

What is the expected salary range for a Tumbling Machine Operator?

Salary expectations for Tumbling Machine Operators can vary depending on experience, industry, and location. According to Salary.com, the national average salary for Tumbling Machine Operators is approximately $25,000 to $45,000 per year.

What are the career advancement opportunities for a Tumbling Machine Operator?

With experience and additional training, Tumbling Machine Operators can advance to roles such as Production Supervisor, Quality Control Inspector, or Process Engineer.