Are you a seasoned Tunnel Kiln Firer seeking a new career path? Discover our professionally built Tunnel Kiln Firer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

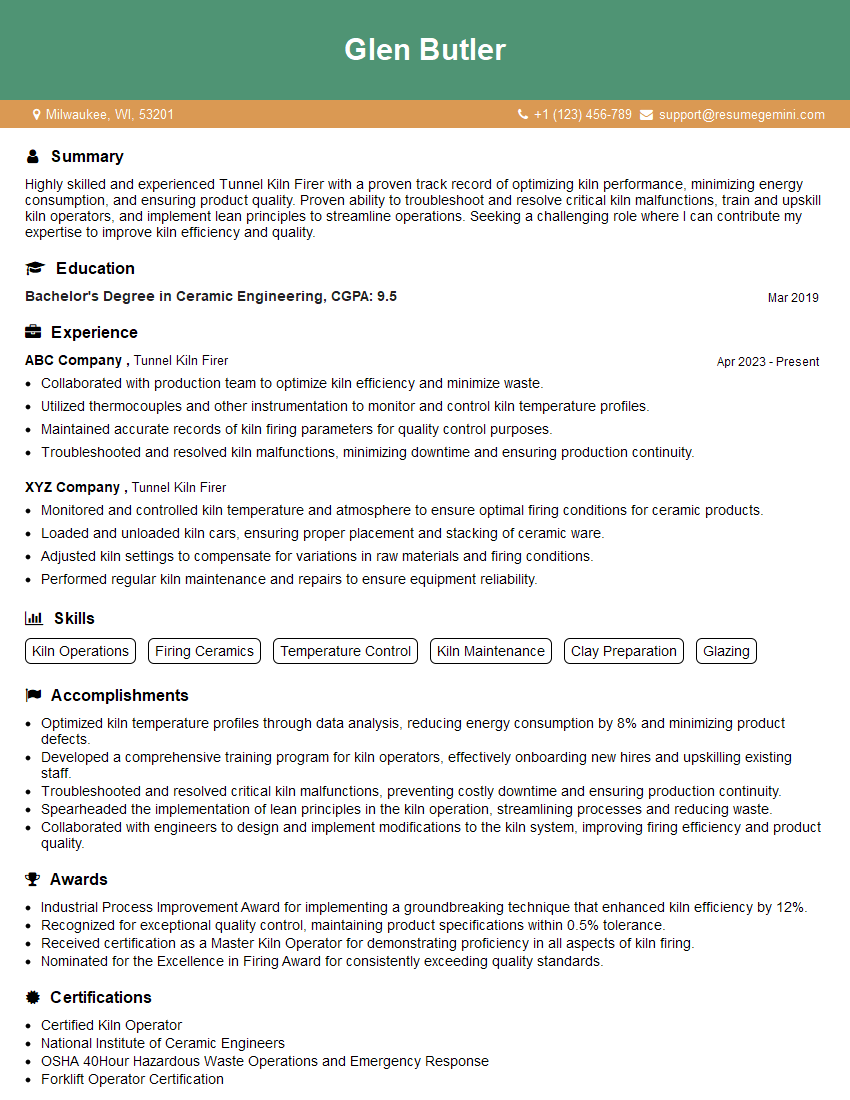

Glen Butler

Tunnel Kiln Firer

Summary

Highly skilled and experienced Tunnel Kiln Firer with a proven track record of optimizing kiln performance, minimizing energy consumption, and ensuring product quality. Proven ability to troubleshoot and resolve critical kiln malfunctions, train and upskill kiln operators, and implement lean principles to streamline operations. Seeking a challenging role where I can contribute my expertise to improve kiln efficiency and quality.

Education

Bachelor’s Degree in Ceramic Engineering

March 2019

Skills

- Kiln Operations

- Firing Ceramics

- Temperature Control

- Kiln Maintenance

- Clay Preparation

- Glazing

Work Experience

Tunnel Kiln Firer

- Collaborated with production team to optimize kiln efficiency and minimize waste.

- Utilized thermocouples and other instrumentation to monitor and control kiln temperature profiles.

- Maintained accurate records of kiln firing parameters for quality control purposes.

- Troubleshooted and resolved kiln malfunctions, minimizing downtime and ensuring production continuity.

Tunnel Kiln Firer

- Monitored and controlled kiln temperature and atmosphere to ensure optimal firing conditions for ceramic products.

- Loaded and unloaded kiln cars, ensuring proper placement and stacking of ceramic ware.

- Adjusted kiln settings to compensate for variations in raw materials and firing conditions.

- Performed regular kiln maintenance and repairs to ensure equipment reliability.

Accomplishments

- Optimized kiln temperature profiles through data analysis, reducing energy consumption by 8% and minimizing product defects.

- Developed a comprehensive training program for kiln operators, effectively onboarding new hires and upskilling existing staff.

- Troubleshooted and resolved critical kiln malfunctions, preventing costly downtime and ensuring production continuity.

- Spearheaded the implementation of lean principles in the kiln operation, streamlining processes and reducing waste.

- Collaborated with engineers to design and implement modifications to the kiln system, improving firing efficiency and product quality.

Awards

- Industrial Process Improvement Award for implementing a groundbreaking technique that enhanced kiln efficiency by 12%.

- Recognized for exceptional quality control, maintaining product specifications within 0.5% tolerance.

- Received certification as a Master Kiln Operator for demonstrating proficiency in all aspects of kiln firing.

- Nominated for the Excellence in Firing Award for consistently exceeding quality standards.

Certificates

- Certified Kiln Operator

- National Institute of Ceramic Engineers

- OSHA 40Hour Hazardous Waste Operations and Emergency Response

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tunnel Kiln Firer

- Highlight your experience and expertise in kiln operations, temperature control, and firing ceramics.

- Demonstrate your ability to optimize kiln performance and minimize energy consumption.

- Showcase your problem-solving skills and ability to troubleshoot and resolve kiln malfunctions.

- Emphasize your commitment to safety and quality in all aspects of your work.

Essential Experience Highlights for a Strong Tunnel Kiln Firer Resume

- Optimize kiln temperature profiles based on data analysis to reduce energy consumption and minimize product defects.

- Supervise and train kiln operators to ensure proper firing techniques, safety protocols, and product quality.

- Monitor and control kiln operation, including temperature, humidity, and firing cycles, to ensure consistent product quality.

- Troubleshoot and resolve kiln malfunctions, perform maintenance, and coordinate repairs to minimize downtime.

- Collaborate with engineers and other team members to implement modifications to the kiln system, improving firing efficiency and product quality.

- Supervise the unloading and post-firing handling of fired products.

- Maintain accurate records and documentation related to kiln operations, energy consumption, and product quality.

Frequently Asked Questions (FAQ’s) For Tunnel Kiln Firer

What are the key qualities and skills required to be a successful Tunnel Kiln Firer?

Key qualities include attention to detail, strong analytical skills, problem-solving abilities, and a commitment to safety. Essential skills include kiln operations, temperature control, kiln maintenance, and firing ceramics.

What is the typical work environment for a Tunnel Kiln Firer?

Tunnel Kiln Firers typically work in manufacturing facilities, industrial plants, or ceramic studios. The work environment can be hot, noisy, and dusty, and may involve working with heavy equipment and hazardous materials.

What are the career advancement opportunities for a Tunnel Kiln Firer?

With experience and additional training, a Tunnel Kiln Firer can advance to roles such as Kiln Supervisor, Production Manager, or Ceramic Engineer.

What are the safety precautions that Tunnel Kiln Firers must observe?

Tunnel Kiln Firers must wear appropriate personal protective equipment, follow established safety protocols, and be aware of potential hazards such as high temperatures, moving machinery, and electrical equipment.

What are the key challenges that Tunnel Kiln Firers may face?

Common challenges include maintaining consistent product quality, optimizing kiln efficiency, troubleshooting kiln malfunctions, and working in a demanding and potentially hazardous environment.

What is the role of technology in modern tunnel kiln firing?

Technology plays a crucial role in modern tunnel kiln firing, including computerized temperature control systems, data analysis tools, and automated loading and unloading systems, which enhance efficiency, consistency, and safety.

How can Tunnel Kiln Firers stay updated with the latest industry trends and best practices?

Tunnel Kiln Firers can stay updated through industry publications, conferences, online forums, and training programs offered by equipment manufacturers and industry associations.

What are the essential soft skills that Tunnel Kiln Firers should possess?

Essential soft skills include teamwork, communication, problem-solving, adaptability, and a strong work ethic.