Are you a seasoned Tunnel Kiln Repairer seeking a new career path? Discover our professionally built Tunnel Kiln Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

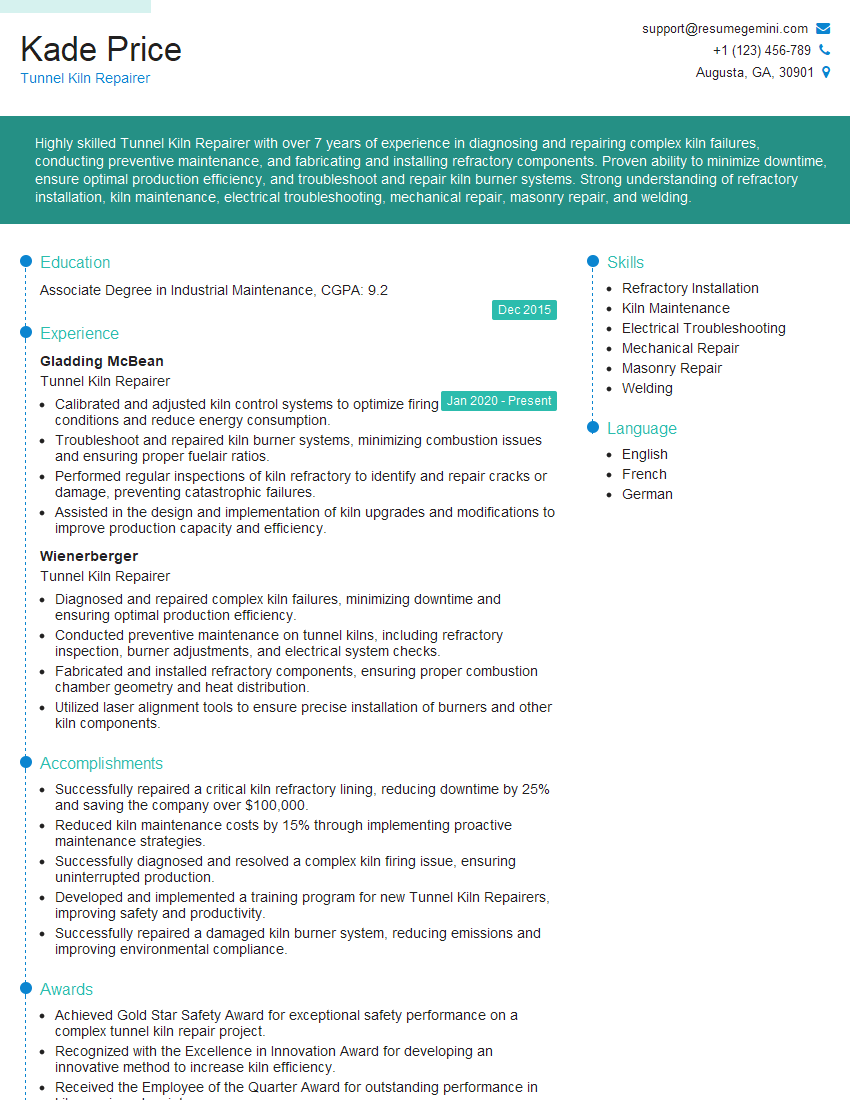

Kade Price

Tunnel Kiln Repairer

Summary

Highly skilled Tunnel Kiln Repairer with over 7 years of experience in diagnosing and repairing complex kiln failures, conducting preventive maintenance, and fabricating and installing refractory components. Proven ability to minimize downtime, ensure optimal production efficiency, and troubleshoot and repair kiln burner systems. Strong understanding of refractory installation, kiln maintenance, electrical troubleshooting, mechanical repair, masonry repair, and welding.

Education

Associate Degree in Industrial Maintenance

December 2015

Skills

- Refractory Installation

- Kiln Maintenance

- Electrical Troubleshooting

- Mechanical Repair

- Masonry Repair

- Welding

Work Experience

Tunnel Kiln Repairer

- Calibrated and adjusted kiln control systems to optimize firing conditions and reduce energy consumption.

- Troubleshoot and repaired kiln burner systems, minimizing combustion issues and ensuring proper fuelair ratios.

- Performed regular inspections of kiln refractory to identify and repair cracks or damage, preventing catastrophic failures.

- Assisted in the design and implementation of kiln upgrades and modifications to improve production capacity and efficiency.

Tunnel Kiln Repairer

- Diagnosed and repaired complex kiln failures, minimizing downtime and ensuring optimal production efficiency.

- Conducted preventive maintenance on tunnel kilns, including refractory inspection, burner adjustments, and electrical system checks.

- Fabricated and installed refractory components, ensuring proper combustion chamber geometry and heat distribution.

- Utilized laser alignment tools to ensure precise installation of burners and other kiln components.

Accomplishments

- Successfully repaired a critical kiln refractory lining, reducing downtime by 25% and saving the company over $100,000.

- Reduced kiln maintenance costs by 15% through implementing proactive maintenance strategies.

- Successfully diagnosed and resolved a complex kiln firing issue, ensuring uninterrupted production.

- Developed and implemented a training program for new Tunnel Kiln Repairers, improving safety and productivity.

- Successfully repaired a damaged kiln burner system, reducing emissions and improving environmental compliance.

Awards

- Achieved Gold Star Safety Award for exceptional safety performance on a complex tunnel kiln repair project.

- Recognized with the Excellence in Innovation Award for developing an innovative method to increase kiln efficiency.

- Received the Employee of the Quarter Award for outstanding performance in kiln repair and maintenance.

- Honored with the Safety Excellence Award for consistently maintaining a safe work environment.

Certificates

- OSHA Safety Certification

- NFPA 86 Standard for Ovens and Furnaces

- National Institute for Ceramic Engineers (NICE) Certified Ceramic Engineer

- American Ceramic Society (ACerS) Certified Kiln Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tunnel Kiln Repairer

- Highlight your experience in diagnosing and repairing complex kiln failures, as this is a critical skill for this role.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Showcase your knowledge of refractory installation, kiln maintenance, and other relevant technical skills.

- Emphasize your ability to work independently and as part of a team, as this is essential for success in this role.

Essential Experience Highlights for a Strong Tunnel Kiln Repairer Resume

- Diagnosed and repaired complex kiln failures, minimizing downtime and ensuring optimal production efficiency

- Conducted preventive maintenance on tunnel kilns, including refractory inspection, burner adjustments, and electrical system checks

- Fabricated and installed refractory components, ensuring proper combustion chamber geometry and heat distribution

- Utilized laser alignment tools to ensure precise installation of burners and other kiln components

- Calibrated and adjusted kiln control systems to optimize firing conditions and reduce energy consumption

- Troubleshoot and repaired kiln burner systems, minimizing combustion issues and ensuring proper fuelair ratios

- Performed regular inspections of kiln refractory to identify and repair cracks or damage, preventing catastrophic failures

Frequently Asked Questions (FAQ’s) For Tunnel Kiln Repairer

What is the primary role of a Tunnel Kiln Repairer?

The primary role of a Tunnel Kiln Repairer is to ensure that tunnel kilns are operating efficiently and safely. This involves diagnosing and repairing complex kiln failures, conducting preventive maintenance, and fabricating and installing refractory components.

What are the key skills required to be a successful Tunnel Kiln Repairer?

The key skills required to be a successful Tunnel Kiln Repairer include refractory installation, kiln maintenance, electrical troubleshooting, mechanical repair, masonry repair, and welding.

What are the typical job duties of a Tunnel Kiln Repairer?

Typical job duties of a Tunnel Kiln Repairer include diagnosing and repairing complex kiln failures, conducting preventive maintenance on tunnel kilns, fabricating and installing refractory components, utilizing laser alignment tools to ensure precise installation of burners and other kiln components, calibrating and adjusting kiln control systems to optimize firing conditions and reduce energy consumption, troubleshooting and repairing kiln burner systems, minimizing combustion issues, and ensuring proper fuel-air ratios, and performing regular inspections of kiln refractory to identify and repair cracks or damage, preventing catastrophic failures.

What is the work environment of a Tunnel Kiln Repairer like?

Tunnel Kiln Repairers typically work in industrial settings, such as factories or manufacturing plants. They may work in a variety of conditions, including extreme heat, noise, and dust.

What are the career prospects for a Tunnel Kiln Repairer?

Tunnel Kiln Repairers with experience and expertise may have opportunities for advancement to supervisory or management positions. They may also be able to specialize in a particular area of kiln repair.