Are you a seasoned Tying Machine Operator seeking a new career path? Discover our professionally built Tying Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

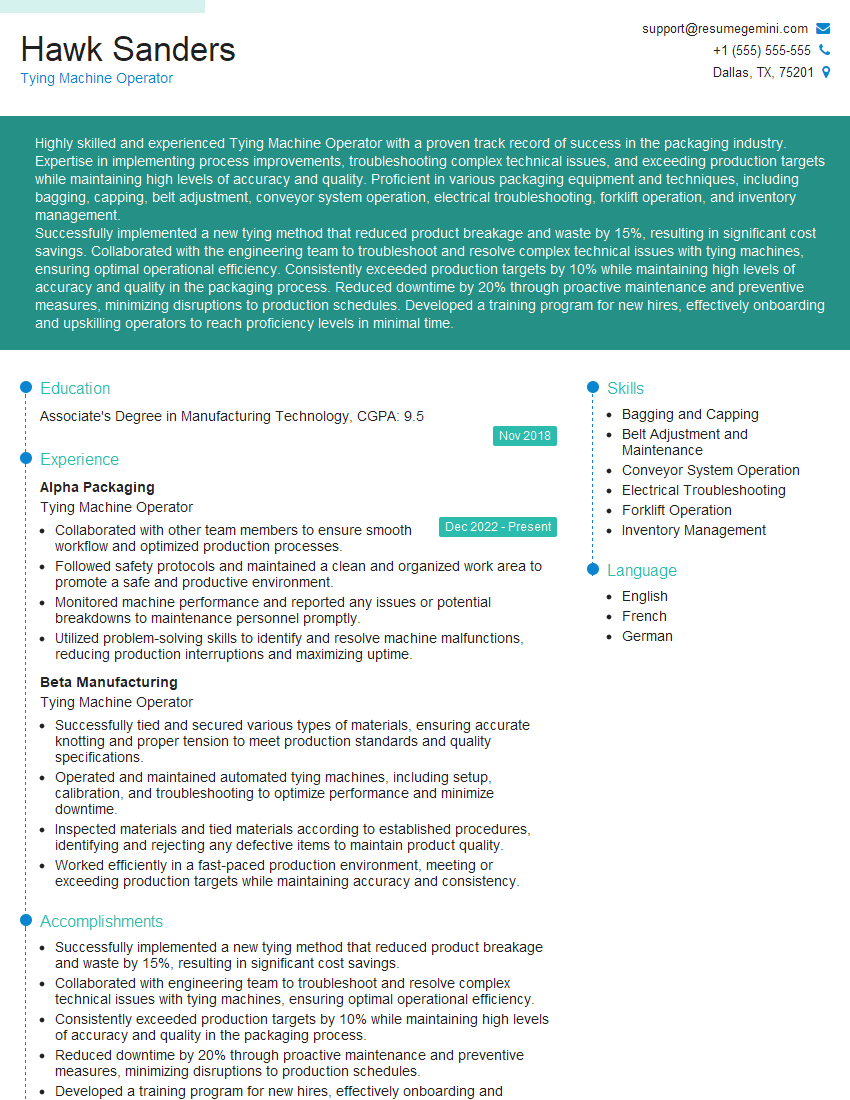

Hawk Sanders

Tying Machine Operator

Summary

Highly skilled and experienced Tying Machine Operator with a proven track record of success in the packaging industry. Expertise in implementing process improvements, troubleshooting complex technical issues, and exceeding production targets while maintaining high levels of accuracy and quality. Proficient in various packaging equipment and techniques, including bagging, capping, belt adjustment, conveyor system operation, electrical troubleshooting, forklift operation, and inventory management.

Successfully implemented a new tying method that reduced product breakage and waste by 15%, resulting in significant cost savings. Collaborated with the engineering team to troubleshoot and resolve complex technical issues with tying machines, ensuring optimal operational efficiency. Consistently exceeded production targets by 10% while maintaining high levels of accuracy and quality in the packaging process. Reduced downtime by 20% through proactive maintenance and preventive measures, minimizing disruptions to production schedules. Developed a training program for new hires, effectively onboarding and upskilling operators to reach proficiency levels in minimal time.

Education

Associate’s Degree in Manufacturing Technology

November 2018

Skills

- Bagging and Capping

- Belt Adjustment and Maintenance

- Conveyor System Operation

- Electrical Troubleshooting

- Forklift Operation

- Inventory Management

Work Experience

Tying Machine Operator

- Collaborated with other team members to ensure smooth workflow and optimized production processes.

- Followed safety protocols and maintained a clean and organized work area to promote a safe and productive environment.

- Monitored machine performance and reported any issues or potential breakdowns to maintenance personnel promptly.

- Utilized problem-solving skills to identify and resolve machine malfunctions, reducing production interruptions and maximizing uptime.

Tying Machine Operator

- Successfully tied and secured various types of materials, ensuring accurate knotting and proper tension to meet production standards and quality specifications.

- Operated and maintained automated tying machines, including setup, calibration, and troubleshooting to optimize performance and minimize downtime.

- Inspected materials and tied materials according to established procedures, identifying and rejecting any defective items to maintain product quality.

- Worked efficiently in a fast-paced production environment, meeting or exceeding production targets while maintaining accuracy and consistency.

Accomplishments

- Successfully implemented a new tying method that reduced product breakage and waste by 15%, resulting in significant cost savings.

- Collaborated with engineering team to troubleshoot and resolve complex technical issues with tying machines, ensuring optimal operational efficiency.

- Consistently exceeded production targets by 10% while maintaining high levels of accuracy and quality in the packaging process.

- Reduced downtime by 20% through proactive maintenance and preventive measures, minimizing disruptions to production schedules.

- Developed a training program for new hires, effectively onboarding and upskilling operators to reach proficiency levels in minimal time.

Awards

- Recipient of the Tying Machine Operator of the Year award for outstanding performance and efficiency in operating automated tying machines.

- Consistently recognized for maintaining an exceptional safety record with zero accidents or incidents during machine operation.

- Achieved certification as a Master Tying Machine Operator by surpassing industry standards for proficiency and accuracy.

Certificates

- Certified Fabricator

- Certified Forklift Operator

- Certified Machine Operator

- Certified Safety Trainer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tying Machine Operator

- Highlight your experience in implementing process improvements and reducing waste.

- Provide specific examples of how you have resolved complex technical issues.

- Quantify your accomplishments with metrics and data whenever possible.

- Demonstrate your commitment to safety and quality.

- Obtain relevant certifications to enhance your credibility.

Essential Experience Highlights for a Strong Tying Machine Operator Resume

- Operate tying machines to secure products for packaging

- Monitor and adjust machine settings to ensure optimal performance

- Inspect products to ensure proper tying and packaging

- Troubleshoot and resolve machine malfunctions and breakdowns

- Perform routine maintenance and cleaning of tying machines

- Maintain a safe and clean work environment

- Follow established quality control standards and procedures

Frequently Asked Questions (FAQ’s) For Tying Machine Operator

What are the key skills required to be a successful Tying Machine Operator?

The key skills required to be a successful Tying Machine Operator include proficiency in various packaging equipment and techniques, such as bagging, capping, belt adjustment, conveyor system operation, electrical troubleshooting, forklift operation, and inventory management. Additionally, strong analytical, troubleshooting, and problem-solving skills are essential, along with a commitment to safety and quality.

What are the career advancement opportunities for Tying Machine Operators?

Tying Machine Operators can advance their careers by developing specialized skills and expertise in packaging machinery and processes. They can move into supervisory or management roles, or become trainers or technical specialists. With additional education and training, they can also pursue careers in engineering, quality control, or production planning.

What are the typical working conditions for Tying Machine Operators?

Tying Machine Operators typically work in manufacturing or industrial settings. They may work in factories, warehouses, or distribution centers. The work environment can be noisy and fast-paced, and may involve exposure to machinery, chemicals, and other potential hazards. However, employers are required to provide a safe and healthy work environment in accordance with OSHA regulations.

What are the earning prospects for Tying Machine Operators?

The earning prospects for Tying Machine Operators vary depending on factors such as experience, skills, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Packaging and Filling Machine Operators, which includes Tying Machine Operators, was $27,990 in May 2021. However, experienced and skilled operators can earn significantly more.

What is the job outlook for Tying Machine Operators?

The job outlook for Tying Machine Operators is expected to be stable over the next decade. The increasing demand for packaged goods is expected to drive growth in the packaging industry, which will require skilled operators to operate and maintain packaging machinery. However, automation and technological advancements may impact the job market for Tying Machine Operators in the long term.

How can I prepare for a career as a Tying Machine Operator?

To prepare for a career as a Tying Machine Operator, you can obtain an associate’s degree in manufacturing technology or a related field. You can also gain experience by working in a manufacturing or packaging environment, or by taking vocational training courses. Additionally, obtaining relevant certifications can enhance your credibility and job prospects.

What are the safety precautions that Tying Machine Operators should take?

Tying Machine Operators should follow established safety protocols and wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs. They should be aware of the potential hazards associated with machinery, electricity, and chemicals, and should take steps to avoid accidents and injuries. Regular training and adherence to safety guidelines are crucial for maintaining a safe work environment.