Are you a seasoned V Groove Cutter seeking a new career path? Discover our professionally built V Groove Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

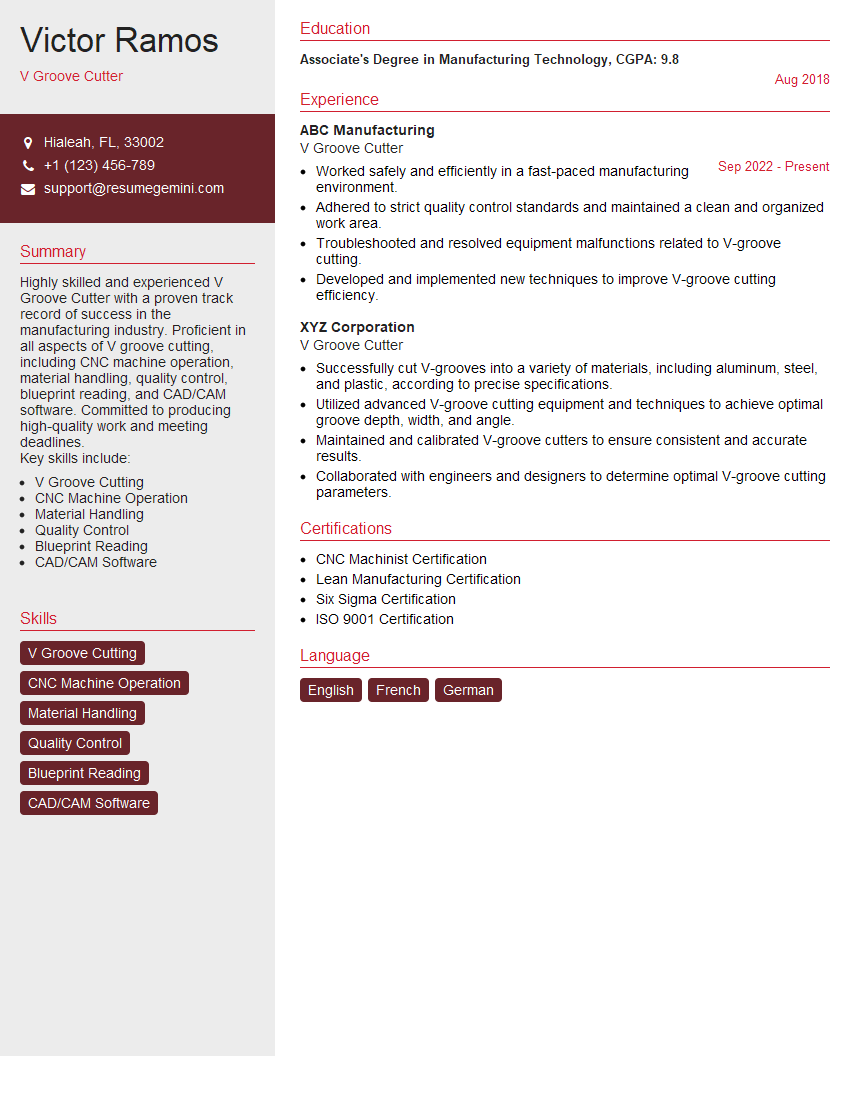

Victor Ramos

V Groove Cutter

Summary

Highly skilled and experienced V Groove Cutter with a proven track record of success in the manufacturing industry. Proficient in all aspects of V groove cutting, including CNC machine operation, material handling, quality control, blueprint reading, and CAD/CAM software. Committed to producing high-quality work and meeting deadlines.

Key skills include:

- V Groove Cutting

- CNC Machine Operation

- Material Handling

- Quality Control

- Blueprint Reading

- CAD/CAM Software

Education

Associate’s Degree in Manufacturing Technology

August 2018

Skills

- V Groove Cutting

- CNC Machine Operation

- Material Handling

- Quality Control

- Blueprint Reading

- CAD/CAM Software

Work Experience

V Groove Cutter

- Worked safely and efficiently in a fast-paced manufacturing environment.

- Adhered to strict quality control standards and maintained a clean and organized work area.

- Troubleshooted and resolved equipment malfunctions related to V-groove cutting.

- Developed and implemented new techniques to improve V-groove cutting efficiency.

V Groove Cutter

- Successfully cut V-grooves into a variety of materials, including aluminum, steel, and plastic, according to precise specifications.

- Utilized advanced V-groove cutting equipment and techniques to achieve optimal groove depth, width, and angle.

- Maintained and calibrated V-groove cutters to ensure consistent and accurate results.

- Collaborated with engineers and designers to determine optimal V-groove cutting parameters.

Certificates

- CNC Machinist Certification

- Lean Manufacturing Certification

- Six Sigma Certification

- ISO 9001 Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For V Groove Cutter

- Highlight your experience and skills in V groove cutting, CNC machine operation, and quality control.

- Quantify your accomplishments with specific metrics, such as the number of parts produced or the percentage of defects reduced.

- Showcase your knowledge of CAD/CAM software and your ability to read and interpret blueprints.

- Emphasize your attention to detail and commitment to producing high-quality work.

Essential Experience Highlights for a Strong V Groove Cutter Resume

- Operate CNC machines to cut V grooves in a variety of materials, ensuring accuracy and precision

- Set up and maintain CNC machines, including loading and unloading materials, and adjusting cutting parameters

- Inspect finished products for quality and accuracy, and correct any defects

- Read and interpret blueprints and CAD/CAM files to ensure proper cutting operations

- Follow safety protocols and maintain a clean and organized work area

- Troubleshoot and resolve machine issues, and perform basic maintenance

- Work effectively as part of a team and meet production deadlines

Frequently Asked Questions (FAQ’s) For V Groove Cutter

What is a V groove cutter?

A V groove cutter is a cutting tool used to create V-shaped grooves in materials. These grooves are often used for decorative purposes, but they can also be used for functional purposes, such as creating channels for wires or pipes.

What are the different types of V groove cutters?

There are many different types of V groove cutters, each designed for a specific purpose. Some of the most common types include single-angle cutters, double-angle cutters, and bullnose cutters.

How do I choose the right V groove cutter for my project?

The best way to choose a V groove cutter is to consider the material you will be cutting, the size and shape of the groove you want to create, and the type of machine you will be using.

How do I use a V groove cutter?

To use a V groove cutter, first secure the material you will be cutting to a stable surface. Then, position the cutter on the material and start the machine. Slowly lower the cutter into the material, taking care to keep the cutter perpendicular to the surface. Once the cutter has reached the desired depth, turn off the machine and remove the cutter.

What are some safety tips for using a V groove cutter?

When using a V groove cutter, always wear safety glasses and gloves. Keep your hands away from the spinning cutter and never leave the machine unattended while it is running.

What is the best way to clean a V groove cutter?

The best way to clean a V groove cutter is to use a soft brush or compressed air. Never use water or other liquids to clean a V groove cutter, as this can damage the cutting edge.

How often should I replace a V groove cutter?

The frequency with which you need to replace a V groove cutter will depend on the type of material you are cutting and the frequency with which you use the cutter. However, it is generally recommended to replace a V groove cutter after every 10-15 hours of use.