Are you a seasoned Vacuum Caster seeking a new career path? Discover our professionally built Vacuum Caster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

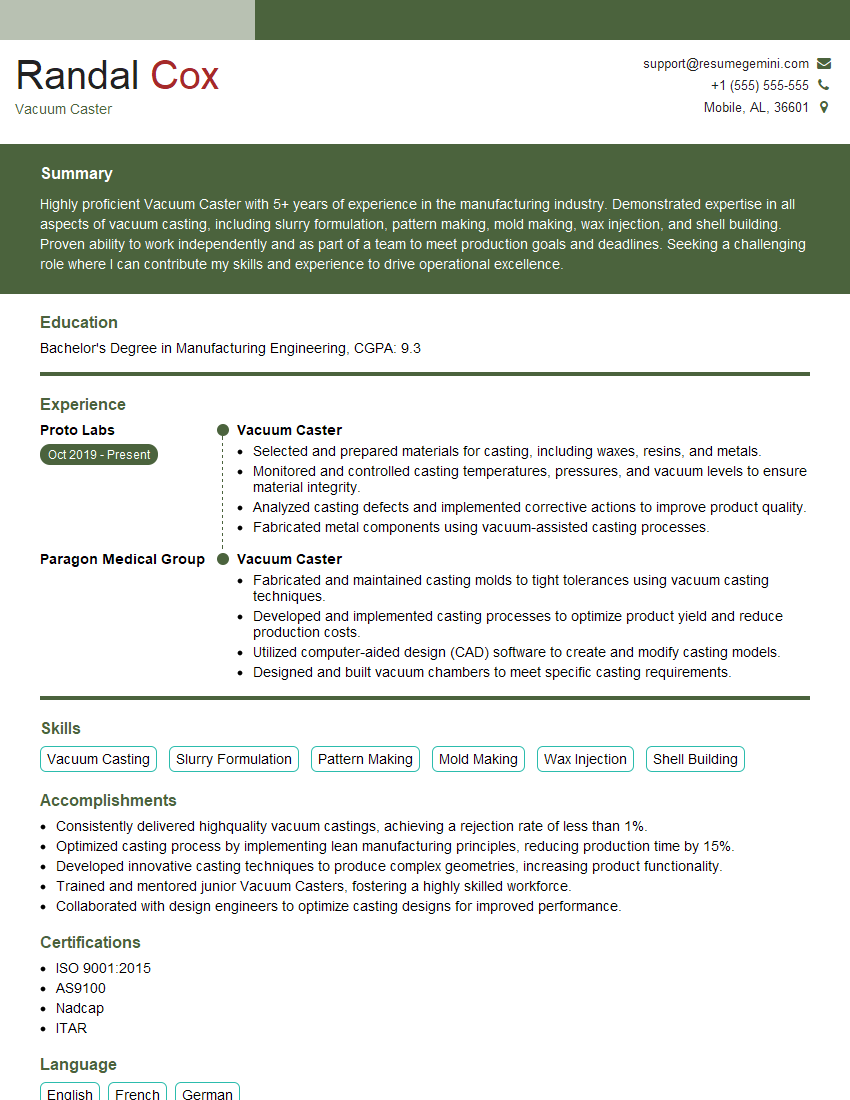

Randal Cox

Vacuum Caster

Summary

Highly proficient Vacuum Caster with 5+ years of experience in the manufacturing industry. Demonstrated expertise in all aspects of vacuum casting, including slurry formulation, pattern making, mold making, wax injection, and shell building. Proven ability to work independently and as part of a team to meet production goals and deadlines. Seeking a challenging role where I can contribute my skills and experience to drive operational excellence.

Education

Bachelor’s Degree in Manufacturing Engineering

September 2015

Skills

- Vacuum Casting

- Slurry Formulation

- Pattern Making

- Mold Making

- Wax Injection

- Shell Building

Work Experience

Vacuum Caster

- Selected and prepared materials for casting, including waxes, resins, and metals.

- Monitored and controlled casting temperatures, pressures, and vacuum levels to ensure material integrity.

- Analyzed casting defects and implemented corrective actions to improve product quality.

- Fabricated metal components using vacuum-assisted casting processes.

Vacuum Caster

- Fabricated and maintained casting molds to tight tolerances using vacuum casting techniques.

- Developed and implemented casting processes to optimize product yield and reduce production costs.

- Utilized computer-aided design (CAD) software to create and modify casting models.

- Designed and built vacuum chambers to meet specific casting requirements.

Accomplishments

- Consistently delivered highquality vacuum castings, achieving a rejection rate of less than 1%.

- Optimized casting process by implementing lean manufacturing principles, reducing production time by 15%.

- Developed innovative casting techniques to produce complex geometries, increasing product functionality.

- Trained and mentored junior Vacuum Casters, fostering a highly skilled workforce.

- Collaborated with design engineers to optimize casting designs for improved performance.

Certificates

- ISO 9001:2015

- AS9100

- Nadcap

- ITAR

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Vacuum Caster

- Highlight your experience and expertise in all aspects of vacuum casting, from slurry formulation to shell building.

- Showcase your knowledge of materials, processes, and equipment used in vacuum casting.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and quality.

- Tailor your resume to each specific job application, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Vacuum Caster Resume

- Developed and implemented vacuum casting processes to optimize production efficiency and quality.

- Formulated slurries to meet specific casting requirements and ensured proper material properties.

- Created patterns and molds using advanced design software and precision machining techniques.

- Injected wax into molds to create patterns for shell building.

- Built and maintained shells using ceramic materials to ensure part accuracy and durability.

- Operated and maintained vacuum casting equipment to ensure optimal performance and safety.

- Consistently exceeded production targets while maintaining high quality standards.

Frequently Asked Questions (FAQ’s) For Vacuum Caster

What is vacuum casting?

Vacuum casting is a metal casting process that involves the use of a vacuum to remove air and gases from a mold cavity before molten metal is poured in. This results in castings with high accuracy, surface finish, and mechanical properties.

What industries use vacuum casting?

Vacuum casting is used in a wide range of industries, including aerospace, automotive, medical, and jewelry. It is particularly well-suited for producing small, complex, and high-precision parts.

What are the advantages of vacuum casting?

Vacuum casting offers several advantages over other casting processes, including: improved accuracy and surface finish, reduced porosity, increased mechanical properties, and the ability to cast complex geometries.

What are the challenges of vacuum casting?

Vacuum casting can be a challenging process, especially for large or complex parts. Some of the challenges include: maintaining a vacuum during the casting process, preventing air leaks, and ensuring proper slurry formulation.

What is the future of vacuum casting?

Vacuum casting is a growing industry, driven by the increasing demand for high-quality, precision parts. As technology continues to advance, we can expect to see even more innovative and efficient vacuum casting processes in the future.

Is vacuum casting a good career choice?

Vacuum casting can be a rewarding career for those with the right skills and experience. The industry offers competitive salaries, opportunities for advancement, and a chance to work with cutting-edge technology.

How can I get started in vacuum casting?

There are a few different ways to get started in vacuum casting. You can: earn a degree in manufacturing engineering or a related field, complete a vocational training program, or apprentice with an experienced vacuum caster.